1982-1989 Ferrari 308 / 328 Quattrovalvole GTB GTS Service Manual (115 Pages)

Complete engine, transmission, and cooling system specifications. Includes detailed procedures for 308 Quattrovalvole and 328 GTB/GTS models with factory torque values and fluid capacities.

Manual Preview

Sample pages from the 1982-1989 Ferrari 308 / 328 Quattrovalvole GTB GTS Service Manual (115 Pages) manual

Purchase & Download

Models Covered & Key Technical Specifications

Ferrari 308 Quattrovalvole, 328 GTB, 328 GTS — 1982–1989 Engineering Reference Handbook | 308/328 Series Packet.

- Nominal Displacement Data: 2926.9 cc (308) and 3186 cc (328) is set to establish the total engine cylinder volume Configuration.

- Prescribed Power Rating: For maximum output, 176.5 kW at 7000 rpm (308) and 198.6 kW at 7000 rpm (328) reaches the rated horsepower Benchmarks.

- System Torque Specification: Peak output yields 259.9 Nm at 5000 rpm (308) and 304 Nm at 5500 rpm (328) crankshaft thrust Standards.

- Technical Compression Ratio: The cylinder head requires 9.2:1 (308) and 9.8:1 (328) for optimal combustion chamber pressure Range.

- Standard Bore Dimension: Cylinder bore is established at 81 mm (308) and 83 mm (328) for accurate piston-to-wall clearance Sequences.

- Defined Stroke Value: Piston travel corresponds to 71 mm (308) and 73.6 mm (328) as the crankshaft throw tolerance Baseline.

Professional Workshop Service Manual & Technical Specifications

Standard Field Manual: Ferrari 308/328 Quattrovalvole GTB GTS Service Manual (1982-1989) Logic-Archive

Design-Core: Ferrari 308 Quattrovalvole, 328 GTB, 328 GTS (F105A, F105C) // Machine-Range: Eight-cylinder mid-engine V90 configuration with carbureted fuel delivery // Calibration-Scope: Comprehensive technical specifications and component reference data for V8 powerplant and transmission systems.

| System Documentation | Technical Component | Reference Material Provided |

|---|---|---|

| Powertrain Assembly | Eight-cylinder engines (2926.9cc and 3186cc displacement) | Complete specifications documented |

| Mechanical Systems | Crankshaft, pistons, connecting rods, cylinder heads | Dimensional tolerances and clearance data included |

| Lubrication & Cooling | Oil circulation, thermal management, fluid specifications | Pressure parameters and capacity information referenced |

Diagnostic procedures address engine disassembly and component verification, enabling technicians to identify cylinder head condition and bearing wear, while also covering clutch system operation and synchronizer function, and further providing gearbox assembly methodology with shifter linkage adjustment protocols, then extending to differential bearing preload procedures and axle shaft joint inspection, concluding with timing system calibration using both goniometric measurement and belt tension verification. The manual documents torque specifications for the eight-cylinder powerplant to ensure proper structural alignment throughout reassembly operations. Wiring harness routing, cooling circuit pressurization, and fuel delivery system component locations are systematically mapped within supplementary sections.

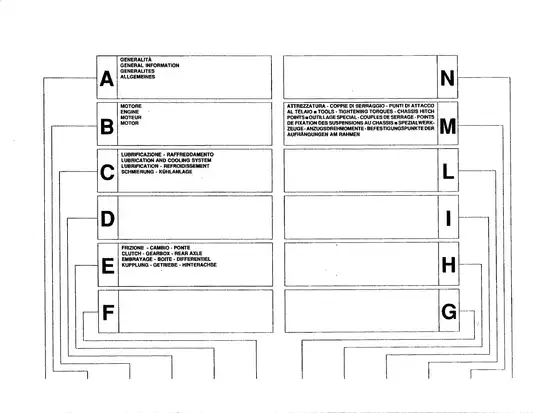

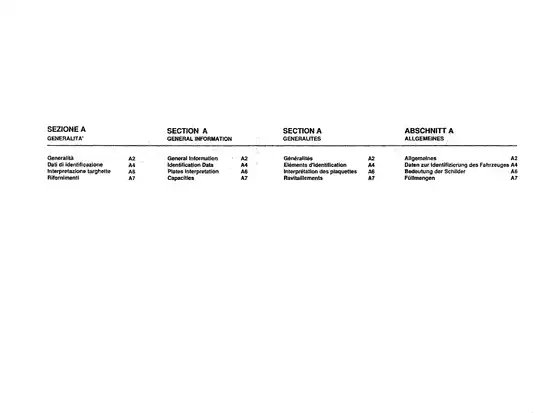

Five chapters included span engine mechanical systems—encompassing block restoration, crankshaft examination, and piston/rod service—connecting through transmission architecture with detailed synchronizer technology explanation and gear ratio tables, advancing to clutch mechanism adjustment procedures and pedal calibration methods, subsequently addressing brake and suspension integration at chassis attachment points, and concluding with complete specification tables referencing bolt torques, oil capacities, and dimensional tolerance boundaries for manufacturer-specified factory service sequences.

FAQ

Customer Reviews

Read what our customers say about this Ferrari Car manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)