Sachs MadAss 125 Service Manual - Repair Guide (109 P.)

Sachs MadAss 125 technical guide detailing engine, chassis, and electrical systems. Covers maintenance, troubleshooting, and disassembly procedures. PN FY152FMI.

Manual Preview

Sample pages from the Sachs MadAss 125 Service Manual - Repair Guide (109 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

| Operational Assembly Electrical Manual: Minibike Sachs MadAss 125 Service Manual - Repair Guide (109 P.) Service-Catalog Engine-Type: Integrated Documentary Database // Calibration-Scope: MadAss 125 Series Edition // Engine-Type: Industrial Sourcebook. | Assessment-Parameter | Value | Logic |

|---|---|---|---|

| Engine Type | FY152FMI | Integrated system component | |

| Bore | 52.40 mm | Standard measurement for internal workings | |

| Compression Ratio | 9.3:1 | Engine efficiency indicator | |

| Tire Pressure | 200 kPa | Operational limit for tire inflation | |

| Battery Type | 12 V 6 Ah MF | Standard electrical power unit | |

| Fuse Rating | 15 A | Safety device for electrical circuit |

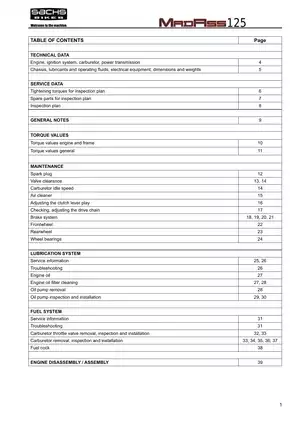

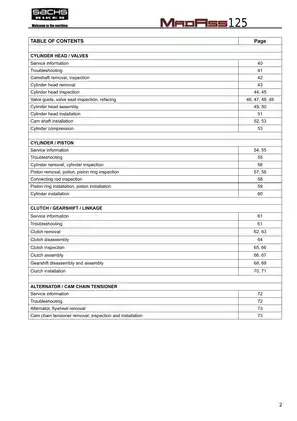

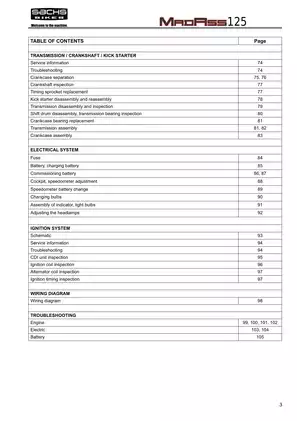

System operation descriptions cover the engine, clutch, transmission, and fuel systems. The documentation addresses maintenance schedules, torque values, and component specifications. Assembly instructions are detailed for various sub-assemblies, including the cylinder head and crankcase. Hydraulic schematics are included for brake system maintenance and troubleshooting. Steering component information is provided for front and rear suspension adjustments. The documentation includes sections on the electrical system, ignition, and wiring diagrams, aiding in diagnosing and resolving electrical faults. Procedures for alternator and cam chain tensioner service are also comprehensively covered, ensuring optimal performance. Troubleshooting charts are provided for common issues across all major systems, facilitating quick resolution. The manual documents torque specifications for critical engine components to ensure proper service interval reliability.

Professional Workshop Service Manual & Technical Specifications

Operational Assembly Electrical Manual: Minibike Sachs MadAss 125 Service Manual - Repair Guide (109 P.) Service-Catalog

| Engine-Type: Integrated Documentary Database // Calibration-Scope: MadAss 125 Series Edition // Engine-Type: Industrial Sourcebook. | Assessment-Parameter | Value | Logic |

|---|---|---|---|

| Engine Type | FY152FMI | Integrated system component | |

| Bore | 52.40 mm | Standard measurement for internal workings | |

| Compression Ratio | 9.3:1 | Engine efficiency indicator | |

| Tire Pressure | 200 kPa | Operational limit for tire inflation | |

| Battery Type | 12 V 6 Ah MF | Standard electrical power unit | |

| Fuse Rating | 15 A | Safety device for electrical circuit |

Featuring a modular arrangement of procedures, specifications, and system overviews, this manual serves as a primary resource. It details the systematic overhaul of the engine, transmission, clutch, and fuel systems. Essential diagnostic procedures and component replacements are clearly outlined. The provided table offers a structured overview of key data points and their associated logic.

System operation descriptions cover

the intricate workings of the engine, clutch, transmission, and fuel systems. Detailed explanations are provided for each component's function and interaction within the overall motorcycle.

The documentation addresses

comprehensive maintenance schedules, specific torque values for critical fasteners, and detailed component specifications. This ensures that all service tasks are performed to factory standards.

Assembly instructions are detailed for

various sub-assemblies, including the cylinder head, crankcase, and transmission components. Step-by-step guidance is provided to ensure correct reassembly.

Hydraulic schematics are included for

brake system maintenance and troubleshooting. This section covers brake fluid checks, pad replacement, and bleeding procedures.

Steering component information is provided for

front and rear suspension adjustments. Information on fork and shock absorber servicing is also included to maintain optimal handling. This manual includes detailed sections on the electrical system, ignition, and comprehensive wiring diagrams, which are crucial for diagnosing and resolving any electrical faults. Procedures for alternator and cam chain tensioner service are also thoroughly covered, ensuring the continued optimal performance and longevity of these vital components. Furthermore, troubleshooting charts are provided for common issues encountered across all major systems, designed to facilitate quick and efficient resolution of problems.

FAQ

Customer Reviews

Read what our customers say about this Sachs Minibike manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)