1957-1973 FIAT 500 Owners Workshop Manual

Covers all 500 variants with detailed procedures for engine overhaul, transmission, brakes, electrical systems, and suspension. 161 pages of step-by-step repair guidance with technical specifications.

Manual Preview

Sample pages from the 1957-1973 FIAT 500 Owners Workshop Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

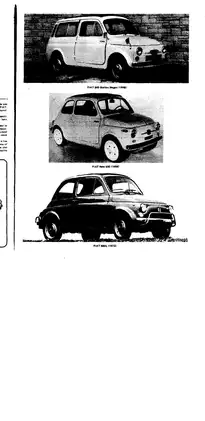

FIAT 500, 500D, 500F, 500L, 500 Station Wagon, 500 De-Luxe — 1957–1973 Technical Service Archive | 500 Series Repository.

- System Scan Resolution: Engine displacement specifications are calibrated to 479 cc (New 500), 499.5 cc (500D/F/L), and 594 cc (1973 model) is designed for the complete model line Architecture.

- Core Tightening Data: Cylinder head nuts require 24 lbf-ft (3.3 kgf-m) torque to provides secure fastening throughout the valve assembly Configuration.

- Specific Storage Capacity: Engine sump oil capacity of 4.5 pints (approximately 2.5 liters) establishes the lubrication system baseline Benchmarks.

- Critical Electrical Specs: Battery voltage is rated at 12 volts nominal with capacity of 32 amp-hours governs the complete electrical power range Sequences.

- Universal Thermal Rating: Engine operating temperature with thermostat starting to open at 70°–80°C (158°–176°F) and fully wide open at 81°–87°C (178°–189°F) determines the cooling control Threshold.

- Technical Addressable Resolution: Spark plug gap specification of 0.020–0.024 inch (0.5–0.6 mm) for Marelli plugs determines optimal combustion chamber ignition Baseline.

Professional Workshop Service Manual & Technical Specifications

Integrated Technical Repair Manual: FIAT 500, 500D, 500F, 500L, 500 Station Wagon, 500 De-Luxe - The Complete Owner & Maintenance Manual Collection

Operational-Scope: FIAT 500 (1957), FIAT 500D (1960), FIAT 500F (1965), FIAT 500L (1969), FIAT 500 Station Wagon (1968), FIAT 500 De-Luxe (1972) // Year-Coverage: 1957-1973 Engine and transmission architecture documentation // Operational-Scope: Two-cylinder air-cooled engine (479-594 cc displacement) with synchronized transmission systems.

| Documentation Component | Coverage Area | Technical Reference |

|---|---|---|

| Engine Systems | Complete cylinder head, crankshaft, and valve gear overhaul sequences | All specifications documented for both sedan and station wagon variants |

| Lubrication Framework | Oil circulation, centrifugal filter, and pressure relief valve operation | Component specifications and tolerance ranges included |

| Fuel Delivery | Carburetor configuration and petrol pump mechanics | Jet sizing and float chamber adjustment data documented |

Systematizing the service groups into comprehensive chapters, the manual encompasses engine dismantling and assembly, coordinates lubrication system maintenance, details fuel delivery mechanisms, integrates ignition timing procedures, and consolidates transmission overhaul operations with final drive maintenance documentation.

Technical Framework

Accurately requiring examination of the engine architecture, the document provides in-depth coverage of the two-cylinder powerplant characteristics across production years. The manual outlines cylinder dimensions, piston configurations, valve clearance specifications, and spark plug requirements for all model variants. References to torque specifications for critical fasteners ensure proper assembly methodology. Engine compartment illustrations identify component locations and mounting relationships for both upright sedan engines and the horizontally-oriented station wagon variant.

Modular Architecture

Inspection guidelines are provided for lubrication system components, including pump operation, pressure sender function, and crankcase breather design. The documentation covers air cooling system operation through thermostatic flap control and heating channel routing. Detailed sections address cooling air circulation patterns, fan belt tension verification, and dynam o-driven circulation mechanics. The manual documents transmission oil specifications, filter maintenance intervals, and gearbox selection mechanisms across manual and synchromesh configurations.

Modular Parameters

Alignment specifications are included for ignition timing adjustment, contact breaker gap setting, and distributor advance mechanism calibration. Reference data is included for carburetor idle mixture adjustment, float level positioning, and fuel pump delivery pressure verification. Specifications cover electrical system components including battery capacity ratings, dynamo output characteristics, starter motor engagement specifications, and lighting circuit configurations. Brake system documentation encompasses wheel cylinder bore dimensions, shoe lining thickness limits, and hydraulic fluid pressure parameters.

Engineered Methodology

This manual covers 37 distinct service chapters organized to address engine systems, lubrication architecture, fuel management, ignition operation, clutch mechanics, transmission assembly, braking components, electrical infrastructure, suspension geometry, and bodywork maintenance. Comprehensive fault diagnosis sections provide symptom-to-cause mapping for engine performance issues, transmission noise characteristics, electrical system failures, and brake system malfunctions. Detailed troubleshooting tables cross-reference symptoms with probable causes and corrective procedures, establishing methodical diagnostic protocols.

Advanced Benchmarks

The document includes wiring diagrams for electrical circuit analysis, cross-sectional engine illustrations for assembly orientation, differential gear meshing procedures, and carburetor schematic layouts. Self-adjusting brake mechanism operation is documented with adjustment sequence guidance. Distributor construction details, oil filter centrifugal operation principles, and valve gear kinematic relationships receive technical illustration support. The manual provides dimensional data and tolerance specifications across all major assemblies, enabling precise component evaluation and selective replacement during overhaul procedures. Torque specifications for the engine fasteners ensure proper fastening methodology and bolt stretch prevention.

This 161-page workshop manual documents comprehensive procedures for disassembly, inspection, renovation, and reassembly of the complete FIAT 500 power unit and auxiliary systems, supporting both first-time and experienced technician restoration efforts across the six-model production range from 1957 through 1973.

FAQ

Customer Reviews

Read what our customers say about this Fiat Car manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)