1985-1986 Kohler M8 / M10 / M12 / M14 / M16 Magnum Single Cylinder Engine Service Manual

Technical reference for Magnum M8, M10, M12, M14, M16 single cylinder engines. Covers diagnostics, periodic maintenance, troubleshooting, and complete disassembly/reassembly procedures. TP-2203-A.

Manual Preview

Sample pages from the 1985-1986 Kohler M8 / M10 / M12 / M14 / M16 Magnum Single Cylinder Engine Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Kohler M8 / M10 / M12 / M14 / M16 (TP-2203-A) - 1985-1986 Service Manual | Engine Kit.

- Established Shipping Weight: 129 lbs does not exceed standard industry limits.

- Operational Print Quality: 1200 dpi establishes the maximum print output Architecture.

- Essential Assembly Torques: 15-20 ft. lbs. signifies essential fastener tightening Protocol.

- Baseline Adjustment Range: For optimal performance, 45 degrees defines the initial valve setting Norms.

- Approved Generation Capacity: The charging system requires 70 Watts for operation Bounds.

- Measured Form Factor: The engine measures 2.94 inches in bore for efficient power Topology.

Professional Workshop Service Manual & Technical Specifications

Consolidated Maintenance Overhaul Manual: Engines (Gasoline) 1985-1986 Kohler M8, M10, M12, M14, M16 Magnum Sincle Cylinder Engines - Factory Diagnostics, Maintenance & Repair Procedures Field-Reference

Operational-Framework: M8, M10, M12, M14, M16 / Engineering-Metrics: Gasoline / Single Cylinder Engine Logic // Operational-Framework: 1985-1986 - TP-2203-A.

| Performance-Element | Technical-Path | Calibration-Standards |

|---|---|---|

| General Engine Specs | Specifications | Torque Values |

| Air Cleaner | Fuel System | Retractable Starters |

| Electrical Systems | Troubleshooting | Compression Release |

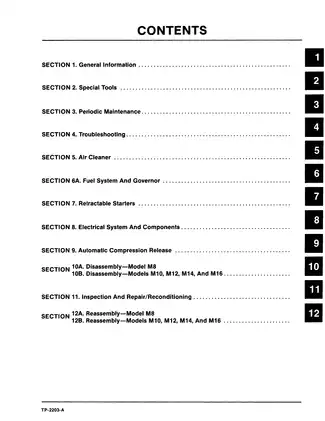

Reference chapters include Section 1. General Information, Section 2. Special Tools, Section 3. Periodic Maintenance, Section 4. Troubleshooting, and Section 5. Air Cleaner. This comprehensive manual details all aspects of engine operation and maintenance for the specified models. It serves as a critical resource for understanding system architecture. Methodically requiring attention to detail, this document outlines procedures for diagnostics, routine maintenance, and complete engine overhaul.

Section 5. Air Cleaner

This section details the disassembly, cleaning, and inspection of the air cleaner assembly, including the paper element and optional precleaner. It ensures optimal air intake for efficient engine performance.

Section 6A. Fuel System And Governor

This chapter covers the fuel system's components, including the fuel tank, fuel pump, and carburetor. It also details the governor system's operation and adjustment, crucial for maintaining consistent engine speed under varying loads.

Section 8. Electrical Systems And Components

This section focuses on the ignition system, lighting, and battery charging systems. It provides troubleshooting guides and diagrams essential for diagnosing and repairing electrical issues.

Section 10A. Model M8 Disassembly Procedure

This section provides a step-by-step guide for disassembling the Model M8 engine, detailing the removal of various components like the muffler, carburetor, and starter.

Section 12B. Models M10, M12, M14, M16 Reassembly

This section outlines the complete reassembly process for the M10, M12, M14, and M16 models, ensuring all components are correctly installed and torqued.

This manual documents torque specifications for critical engine fasteners to ensure proper pivot-point integrity during assembly and maintenance.

FAQ

Customer Reviews

Read what our customers say about this Kohler Engines (Gasoline) manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)