2002-2004 Triumph Daytona 955i / Speed Triple Service Manual

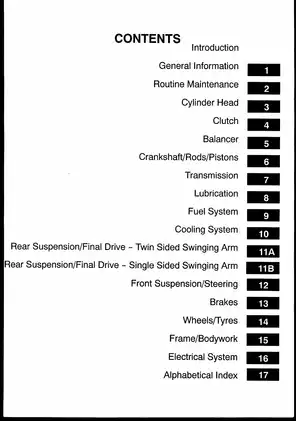

Complete factory service documentation for both Daytona 955i and Speed Triple motorcycles from 2002 onwards. Covers engine rebuilds, transmission service, and electrical diagnostics. Factory part number 3850595.

Manual Preview

Sample pages from the 2002-2004 Triumph Daytona 955i / Speed Triple Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Triumph Daytona 955i & Speed Triple (3850595) — 2002–2004 Service Manual Archive | Daytona/Speed Triple Repository.

-

Nominal Displacement Data: The cylinder volume achieves 955 cc (58.3 cu in) across both engine configurations, representing the core architecture baseline.

-

Principal Power Output: Maximum performance reaches 149 PS at 10700 RPM for the Daytona, and 120 PS at 9100 RPM for the Speed Triple specification.

-

Rated Torque Specification: Peak crankshaft torque is specified at 100 Nm at 8200 RPM (Daytona) and 100 Nm at 5100 RPM (Speed Triple) frameworks.

-

Technical Valve Clearance: Intake valve gap requires 0.10–0.20 mm cold adjustment, while exhaust valves demand 0.20–0.30 mm operating range.

-

Standard Oil Capacity: The lubrication system demands 3.50 litres dry fill volume, with 3.20 litres for wet fill including filter parameters.

-

Defined Fuel Tank Volume: Fuel storage capacity reaches 22 litres with 4 litres remaining trigger point for low level warning threshold.

Professional Workshop Service Manual & Technical Specifications

In-Depth Shop Technical Manual: Motorcycle Triumph Daytona 955i & Speed Triple - Precision Service Handbook Workshop-Compendium

Product-Line: Daytona 955i (2002 onwards), Speed Triple (2002 onwards) // Technical-Scope: Engine and transmission systems Service Logic // Model-Specs: 955cc transverse in-line triple-cylinder DOHC engines with electronic fuel injection and digital ignition.

| Service-Nexus | Diagnostic-Logic | Logic |

|---|---|---|

| Cylinder Head Systems | Valve clearance, camshaft timing, cam chain tension | Complete procedures documented |

| Crankshaft Assembly | Bearing selection, connecting rod installation, piston ring gaps | Specifications and wear limits included |

| Transmission Operation | Selector mechanism, input/output shaft assemblies, starter drive system | Full disassembly and assembly sequences provided |

| Lubrication Circuit | Oil pump operation, pressure relief valve settings, oil cooler integration | Circuit diagrams and component locations detailed |

| Fuel System Management | Injector pulse timing, fuel pressure regulation, throttle body balancing | Electronic control module parameters documented |

Repair procedures are structured around the cylinder head and valves, where intake and exhaust valve specifications cover seat angles, stem clearances, and spring loading characteristics. The documentation details the camshaft installation process, including proper alignment at top dead centre and verification of timing mark positions. Cam chain tensioner setup procedures ensure correct blade positioning and plunger engagement, while valve clearance measurement and adjustment protocols reference shim selection across multiple thickness increments.

Precise Protocol

Disassembly instructions are documented for the crankshaft, connecting rods, and piston assemblies, providing bearing shell selection charts based on journal diameter measurements and crankcase bore dimensions. The manual addresses big end bearing clearance verification using Plastigage methodology, alongside crankpin wear limits specific to each model variant. Connecting rod installation sequences incorporate progressive nut tightening stages and torch turn gauge procedures, ensuring proper fastener engagement without over-stressing components.

Diagnostic Interface

Wear limits are specified for cylinder bore diameter, piston ring end gaps, and gudgeon pin fitment tolerances across both intake and exhaust positions. The document includes detailed inspection protocols for detecting blue discoloration on balancer gears, examining cam chain for stiffness or kinking, and measuring suspension bearing grease distribution. Service limit tables reference maximum acceptable clearances for main bearing journals, camshaft outrigger positions, and transmission selector fork grooves.

Modular Threshold

System operation descriptions cover the electronic fuel injection architecture, featuring barometric pressure sensing integrated within the engine control module and intake air temperature compensation via dedicated airbox sensors. The documentation references closed-loop oxygen sensor feedback during idle and cruise conditions, with long-term fuel trim adaptation procedures that automatically adjust mixture ratios based on exhaust gas content analysis. Throttle position sensor voltage mapping and coolant temperature sensor resistance data enable precise fueling calculations across thermal operating ranges.

Precise Framework

The documentation addresses the idle air control stepper motor positioning system, which regulates bypass air flow to maintain stable idle speed and manage engine overrun conditions at altitude. Secondary air injection system operation is described for applicable markets, detailing reed valve depression cycles timed to exhaust valve opening events and solenoid valve energization logic. Purge valve duty cycle control during cold start and hot soak conditions receives detailed explanation, including canister integrity verification and vapor return line routing.

Structured Framework

Assembly instructions are detailed for the fuel tank mounting plate, pressure regulator installation with new O-ring seals, and fuel filter orientation verification with directional arrow alignment. The manual documents torque specifications for the fuel pump mounting plate fixings, noting cautionary measures against overtightening threaded tank inserts. Comprehensive engine oil circuit diagrams distinguish between Daytona and Speed Triple cooling system architectures, with separate oil feed paths to gearbox shafts and crankshaft main bearings. The document includes oil pump rotor clearance limits, pump body tolerance specifications, and oil pressure relief valve opening thresholds set at 75 lb/in², alongside complete oil filter wrench tool identification and replacement interval scheduling. Bolt torque specifications for cylinder head applications ensure proper head gasket sealing, with three-stage tightening procedures and 90-degree final turn methodology documented to prevent gasket failure and maintain long-term reliability.

FAQ

Customer Reviews

Read what our customers say about this Triumph Motorbike manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)