Caterpillar 320C / 320C L Track-Type Excavator Service Manual

This Service Manual provides detailed repair procedures for Caterpillar 320C and 320C L excavators. Ref: 1229 Pages.

Manual Preview

Sample pages from the Caterpillar 320C / 320C L Track-Type Excavator Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Caterpillar 320C / 320C L Track-Type Excavator (1229 Pages) | Workshop Ready Standards-Vault

Documents service procedures for Caterpillar 320C and 320C L excavators. | Series: Excavator | Container: Unit

- Calibrated Containment Volume: 410 L establishes the fuel tank capacity Matrix.

- System Fit Tolerances: 34,300 kPa supports the main relief pressure Standards.

- Published Voltage Specs: 24V establishes the electrical system Margin.

- Authorized Output Performance: 103 kW governs the net power Protocol.

- Core Net Mass: 107 kN achieves the drawbar pull Architecture.

- Standard Fluid Levels: 210 L signifies the hydraulic system Norms.

Professional Workshop Service Manual & Technical Specifications

Caterpillar 320C / 320C L Track-Type Excavator Parts Manual: Caterpillar 320C Full Caterpillar 320C Track-Type Excavator Parts Manual (852 Pages) | Workshop Ready Standards-Vault

Engineering-Base: Full Coverage: 320C Track-Type Excavator / 320C L Track-Type Excavator // Validation-Data: Category: Bulldozer / System: Diesel Engine Logic // Repair-Classification: 6.37L (389 cu in) Displacement.

Diagnostic procedures address the following systems and procedures:

- Power & Drive Core: Features the Caterpillar 3066 Diesel Engine, delivering 138 HP (103 kW) Net Power at 1800 RPM.

- Technical Systems: Includes a Load-Sensing Hydraulic System and Hydrostatic Triple-Reduction Final Drive with Electronic Governor Control.

- Essential Benchmarks: Outlines parameters such as 4980 PSI (34,300 kPa) Main Relief Pressure and 24,100 lb (107 kN) Drawbar Pull.

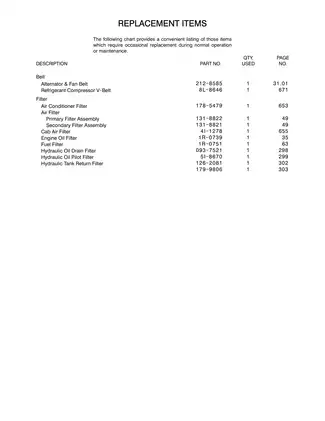

- Capacities & Consumables: Details tank capacities including a 108.3 gal (410L) Fuel Tank and 7.9 gal (30L) Engine Oil capacity, specifying part numbers for filters like 1R-0739 Oil Filter.

- Operational Controls: Documents the Pilot-Operated Control Mechanism and Control Lever functions.

- Attachments: Lists various attachments, including Bucket Linkage, different Stick configurations, and Tool Control options.

| Identifier | Diagnostic-Logic | Framework |

|---|---|---|

| 320C | Track-Type Excavator | Caterpillar |

| 3066 Engine | Diesel | 6.37L |

| Hydraulic System | Load-Sensing | 4980 PSI |

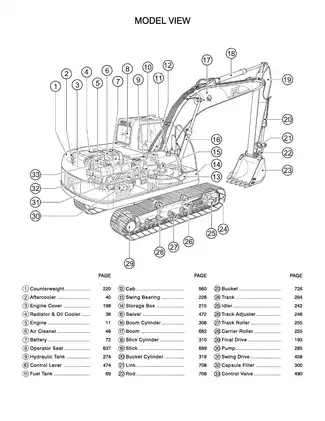

This manual details the following systems and procedures:

- Engine Arrangement: Covers basic engine components, lubrication systems, cooling systems, and air intake/exhaust systems.

- Fuel System: Includes information on fuel injection pumps, filters, lines, and nozzles.

- Electrical and Starting System: Details battery and wiring configurations, alternator mounting, and starter motor components.

- Hydraulic Systems: Outlines various hydraulic assemblies such as boom and stick line groups, as well as pump and swing drive components.

- Control Systems: Documents control levers, governor controls, and electrical control units.

Torque specifications are documented for mating surface contact to ensure proper assembly.

Parts identification is covered for a wide range of components including the cab, counterweight, track groups, and various hydraulic and engine components.

FAQ

Customer Reviews

Read what our customers say about this Caterpillar Bulldozer manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)