1992-2006 Argo Avenger, Conquest, Response, Bigfoot, Vanguard Service Manual

Complete technical reference for Argo amphibious all-terrain vehicles including engine, transmission, brake, and clutch systems. Factory documentation for maintenance and repair procedures. Part Number 673-04-1.

Manual Preview

Sample pages from the 1992-2006 Argo Avenger, Conquest, Response, Bigfoot, Vanguard Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Argo 6x6 Bigfoot, Vanguard, Vanguard2, Response, Conquest; 8x8 Avenger, Conquest, Response, Frontier — 1992–2006 Comprehensive Specification Registry | Argo Series Reference Module.

-

Maximum End Play Specification: 480 cc (16 h.p.) Briggs & Stratton V-Twin 4-cycle air cooled engine displacement is established at baseline engine architecture Bounds.

-

Universal Power Framework: 20 h.p. Kawasaki FD620D liquid cooled engine delivers maximum rated horsepower standardized to 60,000 rpm operational threshold Topology.

-

Fundamental Torque Data: Driver clutch nut fastening reaches 100 FT. LBS. (135.6 N·m) peak crankshaft assembly requirement Matrix.

-

Specific Dimensional Limits: Fuel tank capacity requires 32 litres (7.0 Imperial gallons, 8.4 U.S. gallons) for standard vehicle operation Standards.

-

Published Torque Data: Brake caliper assembly mounting specifies 45 FT. LBS. (61.0 N·m) pressure application margin for transmission interface Protocol.

-

System Measurement Bounds: Vehicle load capacity represents 454 kg (1000 lbs.) land rating with maximum 317 kg (700 lbs.) water displacement capability Guidelines.

Professional Workshop Service Manual & Technical Specifications

Specialized Hydraulic Manual: 6x6 1992-2006 Argo Amphibious All-Terrain Vehicle Service Documentation Engine-Compendium

Documentation-Type: Argo S, SN, BF, RB, C, CB, V, A, B, N, R (1992-2006), Argo 8x8 Avenger, Conquest, Response, Frontier // Diagnostic-Area: Hydraulic and Mechanical System Logic // Performance-Values: 430-page comprehensive technical reference.

| System Component | Coverage Area | Documentation Status |

|---|---|---|

| Engine Operations | Briggs & Stratton, Kawasaki FD620D, Kohler Aegis | Complete specifications provided |

| Brake Systems | Hydraulic and mechanical caliper assemblies | Reference procedures included |

| Clutch Assembly | Driver and driven torque converter mechanisms | Service procedures documented |

| Drive Chain System | Tensioner assemblies and sprocket maintenance | Detailed guidance available |

| Electrical Wiring | Battery, starter, charging systems with schematics | Complete wiring diagrams included |

| Axle and Wheel System | Bearing extensions, idler shafts, tire specifications | Installation and removal procedures |

| Fuel System | Tank removal, filter replacement, venting specifications | See Chapter FS reference |

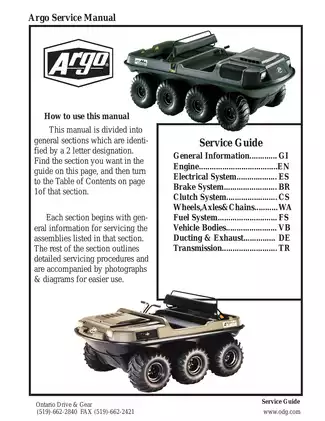

The documentation provides guidance on multiple drive system sections including general information, engine removal procedures, electrical component service, brake system maintenance, clutch system operation, wheels and axles configuration, fuel system layout, and vehicle body assembly. Steering and hydraulic brake assembly procedures are detailed for models manufactured throughout the specified production years. Transmission information encompasses gear shifting operations, drive belt functionality, and torque converter system dynamics.

Diagnostic Benchmarks

System operation descriptions cover engine oil maintenance, air filter inspection, spark plug service, and coolant level verification across Briggs & Stratton V Twin, Kawasaki liquid-cooled, and Kohler engines. The document addresses charging system inspection, battery fluid level monitoring, and electrical connection maintenance for vehicles ranging from early 1992 production through 2006 specifications. Ignition system wiring and starter motor configuration data are included for multiple engine variants.

Modular Nexus

The documentation addresses brake system component inspection, hydraulic fluid condition assessment, and mechanical brake pad wear evaluation. Assembly instructions are detailed for master cylinder reassembly, brake caliper disassembly, and hydraulic plunger pin adjustment procedures. Brake disc removal, installation, and alignment specifications are documented for transmission-mounted applications across 6x6 and 8x8 configurations.

Core Parameters

Hydraulic schematics are included for steering lever travel adjustment, brake cooling fan operation, and master cylinder piston positioning. Chain tensioner system assembly procedures reference both earlier upper-lower block designs and later semi-self-adjusting cam mechanisms. Idler chain deflection parameters, drive chain connecting link installation, and sprocket alignment procedures are documented with specific measurement tolerances.

Strategic Interface

Removal and reinstallation procedures encompass engine mounting to power pack frame assemblies, firewall quick-release mechanisms, and fuel tank accessibility for maintenance operations. The manual documents torque specifications for the drivetrain system to ensure proper fastener security and documents torque specifications for the transmission assembly to ensure proper mechanical integrity. Bearing extension installation, axle seal replacement, and wheel assembly procedures provide complete component orientation guidance.

Ontario Drive & Gear Limited (PH. 519-662-2840) // Part #673-04-1 // Original Publication 05/06

FAQ

Customer Reviews

Read what our customers say about this Case 6x6 manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)