1992-1998 BMW 3 Series M3/318i/323i/325i/328i Service Manual

E36 platform service procedures for sedan, coupe, and convertible models. Complete factory maintenance, diagnostics, and repair specifications for M42, M44, M50, M52, S50US, and S52US engines.

Manual Preview

Sample pages from the 1992-1998 BMW 3 Series M3/318i/323i/325i/328i Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

BMW 3 Series E36 (M3, 318i, 323i, 325i, 328i) — 1992–1998 Mechanical Digest Sourcebook | 3 Series Kit.

- Verified Rotational Force: The M44 engine is rated at 103 hp at 6000 rpm as a maximum power Architecture.

- Key Storage Capacity: For optimal fuel management, the engine displacement reaches 2.8 L (170.4 cu in) on the M52 engine Norms.

- Prescribed Fit Tolerances: The compression ratio is designed for 10.2:1 on premium fuel combustion Bounds.

- Nominal Climate Specs: Operating coolant capacity spans 10.5 L (11.1 US qt) for the M52/S52 engine Topology.

- Design Travel Rate: Maximum engine speed supports 6000 rpm for peak horsepower delivery Matrix.

- Designated Clamp Forces: Cylinder head fasteners is calibrated to 30 Nm in stage one tightening Standards.

Professional Workshop Service Manual & Technical Specifications

Specialized Configuration Safety Manual: BMW 3 Series (E36) M3, 318i, 323i, 325i, 328i Service Documentation Factory-Standards

Design-Core: BMW M3, 318i, 323i, 325i, 328i sedan, coupe, convertible (1992–1998) // Technical-Domain: Engine, transmission, suspension, electrical systems service logic // Asset-ID: 757-page factory service documentation, OBD I/II diagnostics support.

| Performance-Element | Operational-Logic | Validation-Data |

|---|---|---|

| Cylinder head assemblies | Double overhead camshaft chain timing procedures | Chapter references 113, 116, 117 provided |

| Transmission systems (manual/automatic) | Service intervals and rebuild documentation | Chapters 200–260 included |

| Brake and suspension networks | Inspection and adjustment protocols | Chapter 340 specifications documented |

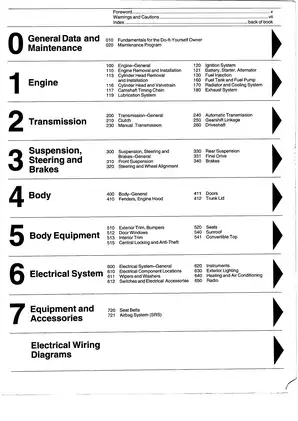

The repository is divided into nine primary sections encompassing engine fundamentals, powertrain systems, chassis architecture, body structures, electrical wiring schematics, and equipment integration. Documentation includes engine removal procedures, camshaft timing chain adjustment, cylinder head reconditioning methodology, lubrication system maintenance, and ignition system diagnostics, plus transmission service covering both manual clutch hydraulics and automatic transmission fluid protocols, and comprehensive suspension inspection procedures addressing front and rear geometry, steering alignment verification, and brake system component wear assessment.

Diagnostic Protocol

Careful attention to On-Board Diagnostics (OBD) enables technicians to retrieve fault codes stored in engine control modules across both OBD I (1992–1995 models) and OBD II (1996–1998 models) platforms. The document references includes detailed fault code tables, sensor testing methodology for crankshaft position sensors, camshaft synchronization verification, and oxygen sensor efficiency monitoring to support catalytic converter diagnostics.

Strategic Methodology

Removal procedures are documented for engine assemblies, cylinder heads with valve train components, timing chain systems incorporating VANOS variable valve timing control units, and integrated fuel injection rail assemblies. The manual provides torque specification standards for all critical fastening points, including stretch-bolt protocols requiring replacement after removal, and procedural sequences for crankshaft and camshaft positioning using specialized locking tools to ensure proper valve train geometry alignment.

Precise Methodology

Technical specifications are provided for compression pressure validation, hydraulic valve adjuster inspection protocols on M44 engines, and cam follower serviceability assessment across all engine variants (M42, M44, M50, M52, S50US, S52US). Documentation includes valve guide wear tolerance data, valve seat dimension references, spring fatigue evaluation criteria, and head gasket resurfacing limits to guide cylinder head reconditioning decisions.

Structured Benchmarks

Factory specifications are documented for engine oil viscosity grade selection according to ambient temperature ranges, coolant mixture ratios using phosphate-free formulations, brake fluid replacement intervals, automatic transmission fluid specifications (Dexron III ATF designation), and final drive synthetic lubricant requirements with limited-slip differential variant data. The manual documents torque specifications for the fuel system, cooling system connections, and electrical component mounting hardware across all model configurations.

Strategic Threshold

Engine rebuild procedures are documented encompassing piston ring inspection, connecting rod bearing assessment, crankshaft journal examination, and main bearing installation sequences. Service intervals follow BMW's adaptive maintenance indicator system responding to engine operating parameters including speed, temperature, trip duration, and start frequency to determine Oil Service versus Inspection I/II maintenance scheduling. The document includes reference data for electrical wiring diagrams, component location illustrations, and exploded-view assembly sequences to support technician comprehension of complex system integration.

The manual documents torque specifications for camshaft timing components to ensure proper tensioner preload and chain slack elimination during reassembly procedures.

FAQ

Customer Reviews

Read what our customers say about this BMW Car manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)