2000-2003 KTM 250 / 400 / 520 SX / MXC / EXC RACING Engine Service Manual

KTM two-stroke engine service documentation with cylinder head gasket, crankshaft bearing, and transmission repair procedures. Nikasil coating specifications, valve clearance adjustments, and timing chain tensioner data. Part number 3206007-E

Manual Preview

Sample pages from the 2000-2003 KTM 250 / 400 / 520 SX / MXC / EXC RACING Engine Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

KTM 250–525 SX, MXC, EXC Racing — 2000–2003 Detailed Reference Manual | KTM Racing Series Module.

- Verified Assembly Gap: Crankshaft axial clearance corresponds to 0.1–0.2 mm (0.0039–0.0078 in) Margin.

- Key Load Capacity: For optimal lubrication, 1.25 liters achieves the required engine oil volume Protocol.

- Principal Thermal Envelope: The liquid cooling system defines 1 liter coolant with 40% antifreeze coverage Architecture.

- Advanced Size Parameters: The cylinder bore diameter is calibrated to 89.000–89.025 mm (3.5039–3.5049 in) Norms.

- Design Fastening Values: Cylinder head screws are rated at 40–50 Nm (30–38 ft.lb) torque Bounds.

- Designated Running Clearance: Valve stem gap is standardized to 0.12 mm (0.0047 in) cold setting Topology.

Professional Workshop Service Manual & Technical Specifications

Functional Installation Hydraulic Manual: Engines (Gasoline) Official KTM 250 SX, 250 MXC, 250 EXC RACING, 400 SX, 400 MXC, 400 EXC RACING, 520 SX, 520 MXC, 520 EXC RACING - Comprehensive Engine Service Manual (2000-2003) Calibration-Manual

Application-Range: KTM 250 SX, 250 MXC, 250 EXC, 400 SX, 400 MXC, 400 EXC, 520 SX, 520 MXC, 520 EXC (2000-2003) // Application-Range: Single-cylinder four-stroke liquid-cooled / Engine and transmission systems Logic // Application-Range: 170 pages, comprehensive technical documentation covering complete engine service procedures.

| Specification | Technical-Path | Calibration-Spec |

|---|---|---|

| Engine Displacement | 250cc, 400cc, 520cc variants documented | Complete specifications provided |

| Service Procedures | Disassembly, component servicing, assembly phases included | Full procedural documentation |

| Electrical System | Ignition system, charging, starter components covered | Complete electrical schematics included |

| Fuel System | Carburetor types and adjustment data documented | Reference specifications included |

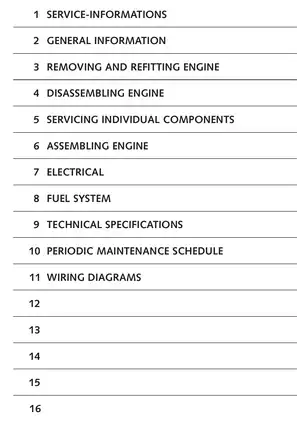

Cataloging major assemblies into oil system documentation, clutch mechanical data, ignition components, fuel system calibration, carburetor adjustment sequences, transmission assembly phases, and exhaust system configuration represents the scope of this comprehensive reference work. The manual organizes engine procedures through systematic component breakdown, covering lubrication circuits through oil pump operation, clutch functionality via disc and spring assembly data, ignition system timing through pulser coil resistance measurements, fuel delivery via carburetor jet sizing and float calibration, gear engagement through transmission shaft assembly, electrical power generation via alternator specifications, and cooling system circulation through water pump operation.

Integrated Architecture

Correctly requiring systematic documentation, the manual presents sixteen major chapters addressing foundational engine systems and periodic service requirements. Service intervals are documented for oil filter replacement, spark plug inspection, and hydraulic clutch fluid maintenance across specified operating hour schedules. Engine lubrication receives dedicated coverage through oil circuit diagrams showing long oil screen positioning, bypass valve function, and oil nozzle spray patterns for piston cooling. The document provides detailed exploded drawings and numbered component references throughout.

Diagnostic Threshold

Component locations are identified for all major engine systems including crankshaft bearing positions, connecting rod assembly points, cylinder head mounting surfaces, and transmission shaft alignment specifications. Calibration requirements are specified for valve clearance measurement, carburetor mixture adjustment, throttle cable slack verification, and hand decompression lever backlash settings. The manual includes reference data for engine oil grade specifications, cooling liquid composition ratios, and fuel quality requirements meeting RON 95 minimum octane ratings.

Structured Standard

Electrical system documentation covers battery specifications, charging voltage parameters at idle and load conditions, spark plug resistance measurements, ignition coil ohm ratings, and stator output voltage ranges. Wiring diagrams illustrate connector configurations and cable routing for four different model years (2000-2003), with separate USA and EU variants. The manual documents torque specifications for engine case assembly through fastener tightening sequences and bolt preload requirements.

Technical Protocol

Service procedures are documented for removing and refitting the engine from the frame, disassembling individual components including pistons, valves, and gear assemblies, inspecting bearings and seals for wear limits, and reassembling complete engine units with correct part orientation. Fuel system documentation covers carburetor disassembly procedures for both FCR 35/39 and FCR-MX 37/39/41 variants, including jet needle positioning, float chamber inspection, and accelerator pump diaphragm replacement guidance. The document includes reference tables for bore and piston dimensions across size categories and model variations.

Precise Methodology

Periodic maintenance schedules appear for model years 2000, 2001, 2002, and 2003, specifying service points at 3-hour, 15-hour, 30-hour, 60-hour, and extended service intervals. The manual documents torque specifications for engine case bolts, cylinder head fasteners, primary gear nuts, clutch spring mounting, and valve adjustment counternut tensioning. Valve clearance reference data and spark plug gap measurements are included, and the document documents torque specifications for clutch slave cylinder bolts to ensure proper hydraulic engagement joint prevention.

Sources from PDF Content:

- Chapter 1: Service Information (pages 2-1C through 2-9C)

- Chapter 2: General Information and Oil Systems (pages 2-1C through 2-9C)

- Chapter 3: Engine Mounting and Removal (pages 3-1C through 3-5C)

- Chapter 4: Engine Disassembly Procedures (pages 4-1C through 4-13C)

- Chapter 5: Component Service and Inspection (pages 5-1C through 5-27C)

- Chapter 6: Engine Assembly Procedures (pages 6-1C through 6-17C)

- Chapter 7: Electrical System Documentation (pages 7-1C through 7-11C)

- Chapter 8: Fuel System and Carburetor Data (pages 8-1C through 8-21C)

- Chapter 9: Technical Specifications and Torque Data (pages 9-1C through 9-16C)

- Chapter 10: Periodic Maintenance Schedules (pages 10-1C through 10-11C)

- Chapter 11: Wiring Diagrams for All Models (pages 11-1C through 11-13C)

FAQ

Customer Reviews

Read what our customers say about this KTM Engines (Gasoline) manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)