John Deere 5200 / 5300 / 5400 Tractor Technical Manual PDF

The official Factory-Level Engineering Calibration Manual for John Deere 5200, 5300, and 5400 Tractors, covering detailed service and repair procedures for all units. PN TM1520 (09MAR92)

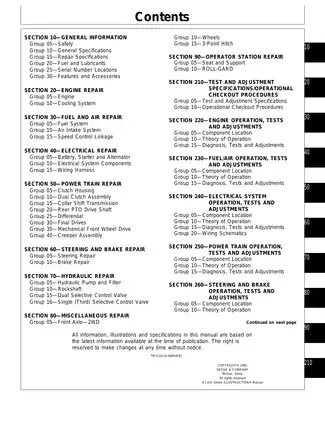

Manual Preview

Sample pages from the John Deere 5200 / 5300 / 5400 Tractor Technical Manual PDF manual

Purchase & Download

Models Covered & Key Technical Specifications

Factory-Level Engineering Calibration Manual: John Deere 5200, 5300, 5400 Tractor Technical Manual – 820 Pages | Shop Standards Service-Dossier Technical reference for John Deere 5200, 5300, 5400 Series Tractors. | TM1520 Record.

- John Deere 3000 Series Engine Specs: 3029DLV01 30kw (40 hp) power output established for the 5200 model Specifications.

- Collar Shift Transmission Details: Nine forward speeds and three reverse speeds are configured at the transmission for optimal operation Standards.

- Open-Center Hydraulic System: Tandem gear hydraulic pumps are driven directly off engine timing gears Matrix.

- PTO Power Rating: Rear PTO operates at 540 rpm for efficient power transfer Standards.

- Electrical System Voltage: Utilizes a 12-Volt system for reliable operation Protocols.

- Fuel Tank Capacity: Holds 68 L (18 U.S. gal) for extended operational ranges Norms.

Professional Workshop Service Manual & Technical Specifications

Factory-Level Engineering Calibration Manual: John Deere 5200, 5300, 5400 Tractor Technical Manual – 820 Pages | Shop Standards Service-Dossier

Asset-ID: TM1520-09MAR92 // Performance-Values: Tractor / Engine Logic // Asset-ID: 1992

| Performance-Element | Diagnostic-Logic | Architecture |

|---|---|---|

| Engine | 3029DLV01/3029DLV02/3029TLV01 | 3-Cylinder Diesel |

| Transmission | Collar Shift | 9-Speed Forward |

| PTO | 540 RPM | Live PTO |

| Steering | Hydrostatic Power | |

| Brakes | Wet Disc | Self-Equalizing |

Providing a structural breakdown of the technical information.

The troubleshooting chapter addresses common issues and diagnostic procedures for all major systems. Testing requirements are specified for various components to ensure proper function. Cooling system maintenance is addressed in detail, including radiator and thermostat procedures. Clearance measurements are detailed for critical components to maintain precise operation. Specific procedures are outlined for engine removal and installation. Careful attention is given to the electrical system and component replacement.

This manual documents torque specifications for various components to ensure proper assembly stress control.

FAQ

Customer Reviews

Read what our customers say about this John Deere Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (6)