2000 HP LaserJet 3200/3200S All-in-One Service Manual (268 P.)

Troubleshooting, repair sequences, and component service for LaserJet 3200 series: fuser assembly, paper path diagnostics, scanner recalibration. Ref: C7052A

Manual Preview

Sample pages from the 2000 HP LaserJet 3200/3200S All-in-One Service Manual (268 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

HP LaserJet 3200, 3200S (C7052A, C7053A, C7055A) — 2000 Analytical Database for Engineering Sourcebook Module.

- Prescribed Fit Tolerances: 0.6% (1.5 mm over 250 mm in length) is designed for left print skew deviation Matrix.

- Standard Consumption Data: For optimal operation, 200 watts in continuous copy mode is configured at the maximum rated power consumption Standards.

- Core Thermal Limits: Operating envelope indicates 15–32.5°C (59–90.5°F) for temperature and 20–80% relative humidity Margin.

- Rated Linear Velocity: Print speed controls 9 ppm with 1200 dpi resolution providing output quality Protocol.

- Calibrated Scan Resolution: 600 dpi optical requires 256 levels of gray and 24-bit color capability Architecture.

- Nominal Adjustment Range: Maximum sound pressure level provides 57 dB at operator position for acoustical emissions Norms.

Professional Workshop Service Manual & Technical Specifications

Standard Hydraulic Manual: HP LaserJet 3200 / 3200S All-in-One Service Manual (268 P.) Documentation-Framework

Calibration-Scope: HP LaserJet 3200, 3200S (C7052A, C7053A, C7055A) // Application-Range: Printer / Scanner / Copier / Fax Logic // Technical-Benchmarks: 1200 dpi print resolution, 600 dpi optical scan capability, 9 ppm output specifications.

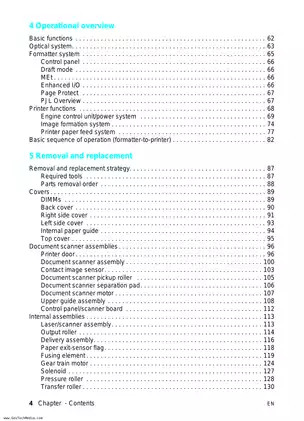

Maintenance information covers product information sections, addressing installation and operation chapters, reviewing operational overview materials, detailing removal and replacement procedures, and presenting troubleshooting diagnostics alongside parts and diagrams resources. The manual provides comprehensive technical documentation for service personnel working with this multifunction device platform.

Calibration requirements are specified for the contact image sensor assembly, document scanner path components, and image formation systems. The documentation addresses photosensitive drum conditioning stages, laser/scanner assemblies, and transfer roller mechanisms within the electrophotographic process architecture.

Electrical system documentation covers the Engine Control Unit (ECU) operations, DC power distribution circuits at +3.3 Vdc, +5 Vdc, and +24 Vdc levels, high-voltage power supply configurations for primary charging and developing rollers, and AC power distribution to fusing assembly heating elements. The formatter system specifications include MCF5202 microprocessor operations at 35 MHz, bidirectional ECP and USB interface protocols, and memory configurations supporting 8 MB RAM standard with DIMM expansion capabilities up to 64 MB.

Disassembly instructions are documented for major subassemblies including document scanner components (contact image sensor, pickup roller assembly, separation pad kit, upper guide assembly), internal printer assemblies (laser/scanner unit, delivery assembly, fusing element, gear train motor, pressure roller, transfer roller, paper-pickup assembly), and electrical components (formatter, LIU, ECU pan). Removal procedures specify required tools, parts removal sequences, and cover disassembly steps progressing through DIMMs, back cover, side covers, internal paper guide, and top cover access points. The manual documents torque specifications for the solenoid assembly to ensure proper corrosion joint prevention.

| Document Section | Component Coverage | Technical Detail Level |

|---|---|---|

| Product Information | Hardware description, firmware capabilities, model specifications (C7052A/C7053A/C7055A) | Complete specifications provided including 200-watt power consumption, 15–32.5°C operating envelope, 9 ppm throughput |

| Installation and Operation | Control panel interface, media selection protocols, document feeder tray operations | Documented procedures for loading media (letter/legal/A4), output path selection, and environmental requirements |

| Maintenance | Consumable life expectancies, cleaning procedures, user-replaceable parts | See Chapter 3 for toner cartridge (2,500 pages), pickup roller (25,000 pages), separation pad specifications |

| Operational Overview | Optical system functions, formatter architecture, ECU/power system, image formation stages | Documented across basic functions, optical systems with LED arrays and rod lens configurations, printer paper feed sequences |

| Removal and Replacement | Field replaceable unit procedures, assembly locations, exploded diagrams | Complete specifications provided for 88 removal sequences with required tool listings |

| Troubleshooting | Basic troubleshooting flowcharts, error code tables, functional checks, service mode access | Documented procedures for engine tests, half-self-test checks, high-voltage power supply verification, T.30 protocol trace analysis |

| Parts and Diagrams | Assembly locations, alphabetical/numerical parts lists, exploded views | Complete part number cross-references with 228 alphabetical and 233 numerical listings |

Wear limits are specified for consumable components throughout the 268-page technical reference. The document includes printer transfer roller assemblies rated at 25,000-page intervals, document scanner pickup roller specifications at 10,000-page service cycles, and fusing element operational parameters. Practical module diagnostics address image formation troubleshooting with repetitive defect ruler measurements, paper feed problem resolution matrices, and control panel error message interpretation tables spanning communication errors, jam detection protocols, and hardware fault codes (50 FUSER ERROR through 81 SERVICE conditions).

FAQ

Customer Reviews

Read what our customers say about this Hewlett Packard Printer manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)