HP Color LaserJet 2550 Series Printer Service Manual (317 P.)

Field service reference for 2550L/Ln/n models with laser/scanner diagnostics, carousel alignment, and imaging drum replacement procedures. Abe008

Manual Preview

Sample pages from the HP Color LaserJet 2550 Series Printer Service Manual (317 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

HP Color LaserJet 2550L, 2550Ln, 2550n — 2004 Engineering Consolidated Dossier | Color LaserJet 2550 Series Volume.

- Nominal System Fill: 20 ppm black and 19 ppm A4 pages is set to letter-size printing Mapping.

- Principal Deviation Limits: For optimal color reproduction, 4 ppm color printing corresponds to maximum throughput Topology.

- Rated Load Capacity: During printing in color mode, 224 W average power consumption dictates active device Matrix.

- Calibrated Cycle Rate: The operating temperature requires 15° to 32.5°C (59° to 90.5°F) Range.

- Documented Package Size: ImageREt 2400 technology is standardized to 2400 dpi color quality through multilevel printing Sequences.

- Design Containment Volume: Standard memory reaches 64 MB with expandable capacity to 192 MB maximum Baseline.

Professional Workshop Service Manual & Technical Specifications

Systematic Service Manual: HP Color LaserJet 2550 Series Printer Electrical-Reference

Performance-Values: HP Color LaserJet 2550L, 2550Ln, 2550n // Reference-Category: Laser Printer / Electrophotographic Logic // Diagnostic-Area: 110-240V power systems, imaging drum calibration, carousel rotation mechanics.

| Specification | Baseline | Validation-Data |

|---|---|---|

| Document Overview | 317-page technical reference | Complete service procedures documented |

| Print Engine Systems | Laser/scanner, imaging drum, transfer belt | Removal and replacement sequences provided |

| Electrical Components | Dc controller, high-voltage PCA, low-voltage power unit | Connector locations and wiring diagrams included |

| Paper Path Mechanics | Tray 1 multipurpose, optional 250-sheet, optional 500-sheet | Jam detection sensor specifications documented |

| Carousel Assembly | Four-position print cartridge rotary mechanism | E-label reader calibration procedures included |

| Fuser Configuration | 110-127V and 220-240V variants | Temperature control circuit diagnostics provided |

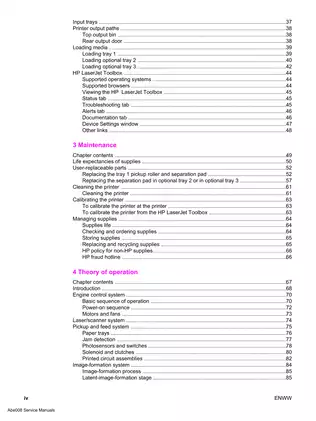

The documentation provides guidance on removal and replacement strategies, covers electrostatic discharge precautions, addresses image-formation system theory, identifies photosensors and switches throughout the paper path, and catalogs printed circuit assemblies across the engine control architecture.

Drivetrain specifications are addressed in the main drive assembly section, detailing the gear train motor interface with registration clutch mechanisms and roller-engaging clutch operations. The rotary-drive assembly coordinates developer motor functions with carousel-engagement sequences, while the fuser motor drives pressure roller rotation through dedicated gear assemblies. Component locations are identified for the laser/scanner beam-detect circuitry, primary charging roller contact points, and transfer belt cleaning mechanisms positioned within the imaging drum cartridge.

Service intervals are documented for separation pad replacement in all three input trays, pickup roller inspection schedules based on page count thresholds, and imaging drum rotation cycle limits. The manual documents torque specifications for the carousel pressure assembly mounting hardware to ensure proper flange face sealing. Waste-toner sensor calibration intervals correlate with density sensor adjustment procedures, while top-of-page sensor alignment depends on registration shutter positioning accuracy.

Service procedures are documented for control panel light message interpretation, supplies status monitoring through E-label memory circuits, and functional checks including engine test protocols. Timing charts illustrate WAIT period sequences, INTR initial rotation phases, and PRINT period carousel positioning. The troubleshooting section references repetitive defect measurement tables, dc controller connection diagrams, and main wiring schematics spanning low-voltage power distribution to high-voltage transformer outputs.

Reassembly procedures are specified forFormatter cage reinstallation with proper cable routing through grounding plate channels, transfer roller plate alignment maintaining correct spring tension values, and top plate positioning over laser/scanner assembly mounts. The parts catalog cross-references assembly locations across front frame, middle frame, rear frame, and power-supply base configurations, with numerical and alphabetical ordering systems for field replaceable unit identification.

FAQ

Customer Reviews

Read what our customers say about this Hewlett Packard Printer manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)