1991 Mitsubishi 3000GT / SL / VR-4 Service Manual (1,146 P.)

Factory service documentation for 3000GT series covering 2,972 cc DOHC engine systems, chassis diagnostics, and body repair procedures with torque specifications.

Manual Preview

Sample pages from the 1991 Mitsubishi 3000GT / SL / VR-4 Service Manual (1,146 P.) manual

Purchase & Download

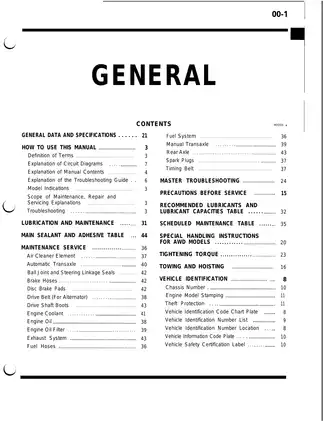

Models Covered & Key Technical Specifications

Mitsubishi 3000GT, 3000GT SL & 3000GT VR-4 — 1991

Technical Catalog for Specification | 3000GT Series Package.

- Designated Cooling Specs: 8.0 liters (8.5 US quarts) is specified as the total coolant system capacity Sequences.

- Primary Throughput Data: For optimal performance, 220 hp at 6000 rpm requires the maximum rated horsepower Baseline.

- Advanced Dimensional Limits: The wheelbase dimension delivers 2,470 mm (97.2 in) as the fixed front-to-rear axle spacing Requirements.

- Defined Torque Data: Peak crankshaft output indicates 307 N·m (226 lb-ft) at 2500 rpm for the VR-4 turbocharged variant Threshold.

- Key Containment Volume: Fuel tank capacity controls 75 liters (19.8 US gallons) for the standard fuel storage system Mapping.

- Essential Environmental Range: Operating temperature range supports -20°C to 40°C (-4°F to 104°F) ambient conditions Configuration.

Professional Workshop Service Manual & Technical Specifications

Reference-Grade Manual: 1991 Mitsubishi 3000GT / SL / VR-4 Service Manual Documentation-Framework

Operational-Framework: Mitsubishi 3000GT, 3000GT SL & 3000GT VR-4 — 1991 // Service-Level: Engine, Chassis & Body / Electronic Control Logic // Product-Line: V60° DOHC Architecture (2,972 cc displacement / Multi-Point Injection).

| Reference Categories | Coverage Scope | Documentation Status |

|---|---|---|

| Engine Control Systems | MPI system diagnostics, fuel injection sequencing, ignition timing protocols | Complete specifications provided |

| Chassis & Drivetrain | Manual transaxle (F5M33), automatic transaxle (F4A33), AWD transfer assembly | Documented |

| Suspension & Steering | Electronic control suspension, 4-wheel steering system, power plant mounting | See Chapter 33-37 |

| Brake Systems | Service brakes, parking brakes, ABS integration procedures | Complete specifications provided |

| Electrical Architecture | Engine control unit circuits, sensor arrays, actuator diagnostics | Documented |

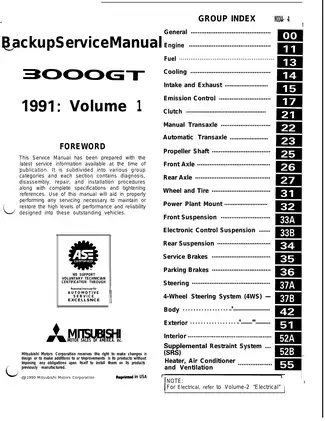

Integrated service sections encompass engine mechanical disassembly procedures, covering fuel system architecture, detailing cooling system maintenance, examining emission control networks, and referencing transmission assemblies.

Verification procedures are included for compression pressure testing across all six cylinders of the 3,972 cc V-configuration powerplant. The manual provides technical reference data for the multi-point injection system, incorporating air flow sensor calibration values, throttle position sensor adjustment protocols, and idle speed control servo specifications. Repair information is provided for camshaft oil seal replacement, timing belt installation sequences, and crankshaft bearing clearance measurements. The document includes coverage of the electronic control suspension system with stepper motor diagnostics and position sensor verification. Brake system specifications are included for disc brake pad thickness limits, hydraulic pressure testing procedures, and anti-lock brake signal integration. Safety procedures are documented for supplemental restraint system component handling, air bag module removal sequences, and clock spring connector service protocols.

The architecture of the 6G72 DOHC engine is presented through sectional diagrams illustrating the dual overhead camshaft configuration with 24-valve arrangement. Consistent technical specifications define the compression ratio at 10.0:1 for non-turbocharged variants and 8.0:1 for turbocharged VR-4 models, with firing order sequence 1-2-3-4-5-6 across both cylinder banks. Service procedures address valve timing specifications, camshaft bearing oil clearance measurements, and piston-to-cylinder bore tolerances. The fuel delivery system documents the Karman vortex air flow sensor operation, electromagnetic injector pulse width modulation, and fuel pressure regulator settings of 335 kPa for non-turbo and 300 kPa for turbocharged applications. Electrical system diagnostics utilize multi-use tester protocols for reading self-diagnosis codes, monitoring sensor voltage outputs, and performing actuator drive tests across engine control unit terminals.

This reference manual documents torque specifications for the engine assembly with cylinder head bolt tightening sequences performed in progressive stages to achieve 120-130 Nm cold-engine values. The manual provides crankshaft main bearing installation procedures, piston ring end gap measurements, and connecting rod bearing oil clearance standards. Transmission service data includes gear ratio specifications for the 5-speed manual F5M33 transaxle with final reduction ratio of 4.153, and the 4-speed automatic F4A33 unit with torque converter stall speed parameters. Chassis documentation addresses front suspension geometry with MacPherson strut removal sequences, and rear multi-link suspension component identification. The document includes coverage of the variable induction control servo utilizing DC motor actuation, waste gate control solenoid valve operation for boost pressure regulation, and EGR temperature sensor circuit diagnostics for California-specification emissions compliance.

FAQ

Customer Reviews

Read what our customers say about this Mitsubishi Car manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)