1998 Honda Integra Service Manual & Repair Guide (1713 Pages)

Cylinder head bolts require dual-torque specification: 22 lb-ft initial, 61 lb-ft final. Covers B18 engine variants with detailed valve clearance protocols and coolant specs.

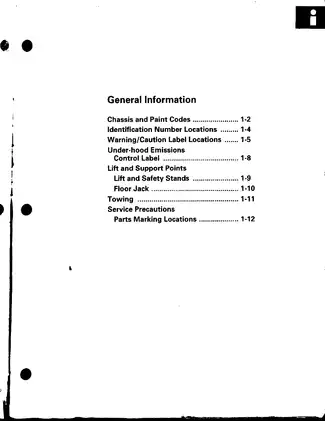

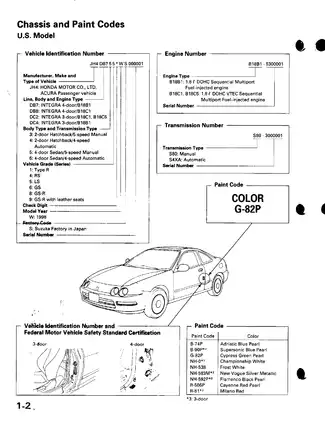

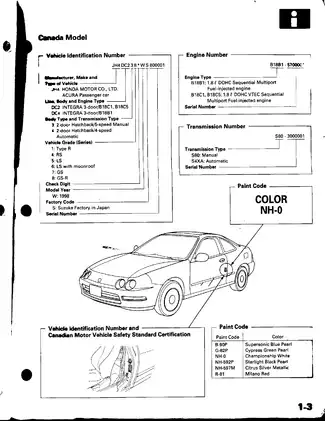

Manual Preview

Sample pages from the 1998 Honda Integra Service Manual & Repair Guide (1713 Pages) manual

Purchase & Download

Models Covered & Key Technical Specifications

Honda Integra RS, LS, GS, GS-R — 1998 Industrial Resource for Documentation | B18 Series Compendium

- Cylinder head bolts require 22 lb-ft for initial torque sequence, then 61 lb-ft for final tightening in the B18 engine block assembly

- Engine oil capacity for B18C1 and B18C5 variants measures between 3.7 L minimum and 4.8 L maximum including filter replacement

- Valve clearance tolerances span 0.08-0.12 mm for intake valves and 0.15-0.20 mm for exhaust valves when measured cold

- Engine coolant operating temperature maintains 176-200°F (80-93°C) range during normal driving conditions with thermostat regulation

- Idle speed specifications call for 750±50 rpm on B18B1 and B18C1 engines, while B18C5 requires 800±50 rpm at operating temperature

- Main bearing cap bolts demand 56 lb-ft (76 N·m or 7.8 kgf·m) torque specification for proper crankshaft assembly

Professional Workshop Service Manual & Technical Specifications

Consolidated Reference Calibration Manual: 1998 Honda Integra Service Manual & Repair Guide (1713 Pages) Service-Dossier

Specification-Class: Honda Integra (RS, LS, GS, GS-R) — 1998 // Performance-Values: B18 Series Module / Clutch System Logic // Specification-Class: Valve clearance tolerances, cylinder head bolt sequences, engine oil capacity specifications.

| Performance-Element | Baseline | Logic |

|---|---|---|

| Engine Assembly | B18B1, B18C1, B18C5 variants | Complete cylinder head removal/installation sequences, crankshaft bearing clearance specifications, valve timing procedures |

| Fuel System Pressure | 320-370 kPa (B18C1/B18C5), 250-310 kPa (B18B1) | PGM-FI system diagnostic terminal locations, fuel injector resistance values, pressure regulator testing protocols |

| Torque Specifications | Cylinder head: 85 N⋅m, Main bearing caps: 64-76 N⋅m | Sequential tightening patterns, connecting rod specifications, flywheel mounting procedures |

| Valve Clearances | Intake: 0.15-0.19 mm, Exhaust: 0.17-0.21 mm | Cold engine measurement procedures, adjusting screw specifications, VTEC rocker arm clearances |

| Transmission Fluid | Honda MTF, 1.9 L capacity | Synchromesh operation principles, gear ratio specifications, clutch hydraulic system bleeding |

| Timing Belt Service | Replace at 105,000 miles | Camshaft timing mark alignment, tensioner adjustment specifications, water pump removal sequences |

| Diagnostic Codes | P0106, P0107, P0108 MAP sensor codes | ECM terminal voltage specifications, connector pinout diagrams, sensor resistance testing |

| Maintenance Intervals | Normal: 7,500 miles, Severe: 3,750 miles | Oil filter replacement schedules, air cleaner service, spark plug specifications |

Providing a structural breakdown of engine removal procedures, the manual addresses cylinder head servicing, addresses timing belt replacement methodology, addresses valve clearance adjustment protocols, and addresses crankshaft installation specifications across comprehensive technical chapters.

Documenting the B18B1 non-VTEC and B18C1/B18C5 VTEC engine variants, this reference material contains complete disassembly sequences for cylinder head components, valve train assemblies, and crankshaft bearing installations. The content specifies cylinder head bolt torque values of 85 N⋅m applied in documented sequential patterns, valve stem-to-guide clearance tolerances of 0.04-0.10 mm for intake valves, and camshaft journal oil clearance specifications ranging from 0.030-0.089 mm. Engine removal procedures document disconnection of fuel lines, electrical connectors, cooling system hoses, and transmission mounting points with step-by-step component identification.

The PGM-FI electronic fuel injection system receives detailed coverage including fuel pressure specifications of 320-370 kPa for VTEC engines and 250-310 kPa for non-VTEC variants, measured at idle with pressure gauge connection to the fuel filter service bolt. Diagnostic procedures enumerate ECM terminal voltage testing specifications, fuel injector resistance values of 1.5-2.5 Ω, and throttle position sensor output characteristics across opening angles. The manual catalogs diagnostic trouble codes including P0106 (MAP sensor range/performance), P0107 (MAP sensor circuit low input), and P0135 (oxygen sensor heater circuit), with corresponding ECM terminal testing protocols and component replacement procedures.

Timing belt replacement methodology encompasses camshaft timing mark alignment specifications, crankshaft TDC positioning procedures, and tensioner adjustment techniques using spring tension measurements. The documented service interval of 105,000 miles includes water pump inspection requirements, valve clearance verification protocols, and crankshaft seal replacement specifications. Camshaft pulley bolt torque values of 37 N⋅m and timing belt adjuster bolt specifications are enumerated alongside AUTO-TENSIONER operating principles for applicable engine variants.

Transmission chapters contain synchromesh mechanism operation principles, gear ratio specifications for all forward gears and reverse, and hydraulic clutch system bleeding procedures using the two-person method. Clutch disc specifications detail facing thickness measurements, spring tension values, and pressure plate diaphragm spring height tolerances. The manual specifies Honda MTF (Manual Transmission Fluid) as the required lubricant with 1.9 L capacity, documenting fill plug torque specifications and fluid level inspection procedures.

Maintenance schedules differentiate normal driving conditions (7,500-mile intervals) from severe service requirements (3,750-mile intervals), defining severe conditions as extensive idling, dusty environments, trailer towing, or mountainous terrain operation. Service procedures catalog engine oil capacity of 3.8 L with filter replacement, API SJ or SH grade specifications, and oil filter torque values. Air cleaner element replacement intervals, spark plug specifications (NGK ZFR5F-11 or equivalent), and cooling system capacity of 6.2 L are documented with corresponding inspection criteria.

EVAP system architecture includes canister purge control valve operation, two-way valve specifications, fuel tank pressure sensor characteristics, and purge flow testing procedures. The manual documents evaporative emission system component locations, vacuum hose routing diagrams, and diagnostic procedures for fuel vapor pressure abnormalities. Fuel tank removal sequences, filler neck specifications, and rollover valve operation principles receive systematic coverage.

Valve train specifications enumerate rocker arm geometry, camshaft lobe lift measurements, valve spring free length tolerances, and valve seat angle specifications of 45°. VTEC system operation receives dedicated coverage including spool valve assembly specifications, rocker arm synchronizing pistons, and oil pressure switch activation thresholds. The manual contains valve guide replacement procedures, valve seat cutting specifications, and cylinder head warpage measurement protocols using straightedge and feeler gauge methodology.

Crankshaft installation procedures specify main bearing cap torque sequences of 64 N⋅m followed by additional 56° rotation, connecting rod bearing oil clearance tolerances of 0.018-0.035 mm, and crankshaft thrust clearance specifications. Piston ring end gap measurements, piston-to-cylinder clearance values, and piston pin interference fit specifications are enumerated. The reference material documents oil pump clearance tolerances, pressure relief valve specifications, and oil pan mounting bolt torque values.

Electrical system chapters catalog ECM connector terminal assignments, sensor voltage specifications, and actuator testing procedures. Oxygen sensor heater circuit resistance values, idle air control valve operation characteristics, and ignition coil primary/secondary winding specifications receive detailed coverage. The manual enumerates EGR system component testing, intake air temperature sensor resistance characteristics across temperature ranges, and coolant temperature sensor voltage output specifications.

Torque Specification Reference:

Cylinder head bolts: 85 N⋅m (sequential pattern) • Main bearing caps: 64 N⋅m + 56° • Connecting rod nuts: 30 N⋅m + 56° • Camshaft pulley: 37 N⋅m • Flywheel mounting: 112 N⋅m • Oil pan bolts: 12 N⋅m • Timing belt adjuster: 44 N⋅m • Intake manifold: 23 N⋅m • Exhaust manifold: 33 N⋅m • Valve cover: 11 N⋅m

FAQ

Customer Reviews

Read what our customers say about this Honda Car manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)