1984-1992 Yamaha 9.9/15 HP Outboard Motor Service Manual

Covers Yamaha 9.9 and 15 HP outboard motors (N-Q models) with full system diagnostics, repair procedures, and detailed component data. Ref: LIT-18616-00-04.

Manual Preview

Sample pages from the 1984-1992 Yamaha 9.9/15 HP Outboard Motor Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Yamaha 9.9/15 HP Outboard Motor (LIT-18616-00-04) - 1984-1992 | Professional Database for Outboard Motors Archive. Verified Consumption Data: The nominal processing speed is 5,000 r/min is set to limit maximum engine output. Key Electrical Load: The lighting coil delivers an output of 80 W using a 4-pole magneto. Principal Cold Start Limits: The spark plug gap limits to 0.9–1.1 mm (0.035–0.043 in) for consistent combustion Baseline. Advanced Form Factor: The total piston displacement is 246 cc (15.0 cu.in.) to produce simultaneous sparks in the two cylinders, a capacitor-discharge ignition (CDI) system is used. Defined Tightening Data: The spark plug tightening torque is 20 Nm (2.0 m·kg, 14 ft-lb). General Power Rating: The engine type is 2-stroke.

Professional Workshop Service Manual & Technical Specifications

Professional Training Technical Manual: Yamaha 9.9 & 15 (N-Q) Outboard Motors (1984–1992) System-Standards

Unit-Designations: Yamaha 9.9/15 (N–Q) Service Manual (LIT-18616-00-04) // Engine-Type: Outboard Motor / Engine Logic // Unit-Designations: Technical Documentation

| TOP | Assessment-Element | System-Path | Calibration-Standards |

|---|---|---|---|

| Nominal Processing Speed: | For optimal operation, | 5,000 r/min is set to limit maximum engine output. | |

| Principal Mass Specs: | For optimal operation, | 150 kg (330 lb) defines the overall unit weight Framework. | |

| Rated Precision Specs: | The | 0.03–0.12 mm (0.001–0.005 in) dictates the piston-to-cylinder clearance Logic. | |

| Standard Locking Torques: | The | ignition timing is standardized to 5°–30° Range. | |

| Technical Measurement Bounds: | For optimal operation, | 1.35 US gal (5 L/h) is set to define maximum fuel consumption Benchmarks. | |

| Defined Cycle Rate: | The | spark plug gap limits to 0.9–1.1 mm (0.035–0.043 in) for consistent combustion Baseline. |

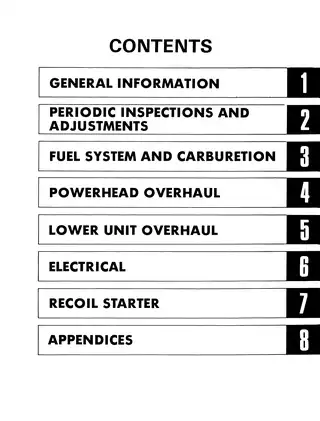

Maintenance hierarchies are structured into

- GENERAL INFORMATION

- FUEL SYSTEM AND CARBURETION

- ELECTRICAL

- GEAR CASE DISASSEMBLY

- ENGINE ASSEMBLY AND ADJUSTMENT

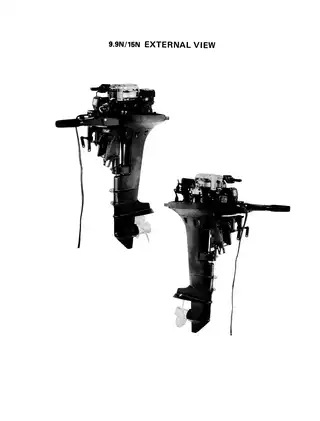

This manual documents the complete diagnostic and repair procedures for Yamaha 9.9 and 15 horsepower outboard motors, covering model years 1984 through 1992 (N-Q series). It details the systems and components integral to the reliable operation of these engines.

Reassembly procedures are specified for engine components, including the power head, lower unit, and recoil starter assembly, ensuring correct assembly and functionality after maintenance.

Service intervals are documented for all major maintenance tasks, encompassing periodic inspections, lubrication schedules, and recommended checks to ensure longevity and optimal performance.

Component locations are identified for all key parts, facilitating easier identification and access during disassembly and repair processes. This includes detailed diagrams and labeling.

Service procedures are documented for common maintenance and repair tasks, such as carburetor adjustment, ignition system checks, and lower unit overhaul, providing step-by-step guidance.

Calibration requirements are specified for critical engine parameters, including idle speed, spark plug gap, and fuel flow, to ensure the engine operates within factory specifications.

The manual details torque specifications for critical engine components to ensure proper axial load stability during assembly and maintenance.

FAQ

Customer Reviews

Read what our customers say about this Yamaha Outboard Motor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)