Comprehensive STILL Electric Forklift Workshop Manual, Models R20-15, R20-16, R20-18, R20-20

Manual Preview

Sample pages from the Comprehensive STILL Electric Forklift Workshop Manual, Models R20-15, R20-16, R20-18, R20-20 manual

Purchase & Download

Models Covered & Key Technical Specifications

- R20-15 (2008-2014)

- R20-16 (2008-2014)

- R20-18 (2008-2014)

- R20-20 (2008-2014)

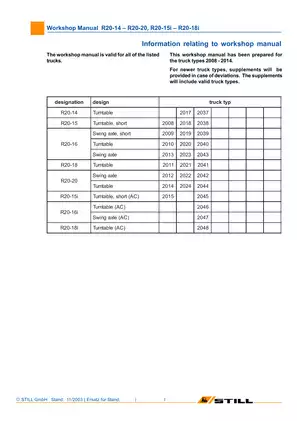

- R20-14 Turntable (2017-2024 / 2037-2044)

- R20-15 Turntable, short (2008-2014 / 2018-2024 / 2038-2044)

- R20-15 Swing axle, short (2009-2014 / 2019-2024 / 2039-2044)

- R20-16 Turntable (2010-2014 / 2020-2024 / 2040-2044)

- R20-16 Swing axle (2013-2014 / 2023-2024 / 2043-2044)

- R20-18 Turntable (2011-2014 / 2021-2024 / 2041-2044)

- R20-18 Swing axle (2012-2014 / 2022-2024 / 2042-2044)

- R20-20 Turntable (2014 / 2024 / 2044)

- R20-15i Turntable, short AC (2015 / 2045)

- R20-15i Turntable AC (2046)

- R20-16i Swing axle AC (2047)

- R20-18i Turntable AC (2048)

Professional Workshop Service Manual & Technical Specifications

STILL Electric Forklift Workshop Manual – R20-14 to R20-20 & R20-15i to R20-18i Series

This professional-grade workshop manual is the definitive technical resource for the STILL R20 series, covering both the standard DC and the advanced AC (i-series) electric fork trucks. Spanning over 1,000 pages of deep-dive technical documentation, this manual is designed for master mechanics and fleet managers who require factory-level precision for maintenance, diagnostics, and complex overhauls.

Comprehensive Model Coverage

This manual includes all documented configurations, including Turntable and Swing Axle designs across their respective production cycles:

- R20-15 (2008-2014)

- R20-16 (2008-2014)

- R20-18 (2008-2014)

- R20-20 (2008-2014)

- R20-14 Turntable (2017-2024 / 2037-2044)

- R20-15 Turntable, short (2008-2014 / 2018-2024 / 2038-2044)

- R20-15 Swing axle, short (2009-2014 / 2019-2024 / 2039-2044)

- R20-16 Turntable (2010-2014 / 2020-2024 / 2040-2044)

- R20-16 Swing axle (2013-2014 / 2023-2024 / 2043-2044)

- R20-18 Turntable (2011-2014 / 2021-2024 / 2041-2044)

- R20-18 Swing axle (2012-2014 / 2022-2024 / 2042-2044)

- R20-20 Turntable (2014 / 2024 / 2044)

- R20-15i Turntable, short AC (2015 / 2045)

- R20-15i Turntable AC (2046)

- R20-16i Swing axle AC (2047)

- R20-18i Turntable AC (2048)

Technical Excellence & Key Specifications

The R20 series is known for its dual-motor front drive and high maneuverability. This manual provides the specific data needed to maintain these high standards:

- Advanced Drive Systems: Detailed service for AE 18-02 wheel drive units, including reduction gear cross-sections and precise torque specs (e.g., slotted nut M60x2 at 650 + 20 Nm).

- Steer Axle Versatility: Full coverage for both the 90-degree Turntable steering and the 80-82 degree articulating Swing Axle variants.

- Hydraulic Precision: Complete schematics for the control valve blocks, featuring pressure relief valve settings (fixed at 250 bar) and auxiliary functions (3rd and 4th hydraulics).

- Digital Control & Electronics: Instructions for the A9 controller, including parameterization for drive programs 1–5 (VMAX, acceleration, and deceleration settings).

- Insulation & Safety: Essential testing procedures for electrical components, requiring a minimum insulation resistance of 48 kOhm (1000 Ohm/Volt).

Detailed Workshop Contents:

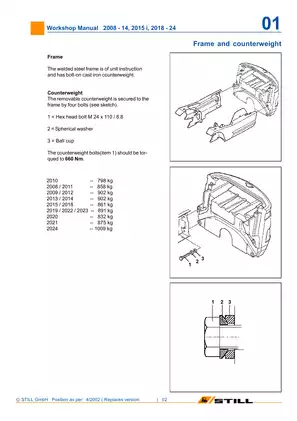

- Chassis & Frame: Procedures for jacking up the truck, frame unit construction, and counterweight bolt torques (660 Nm).

- Drive Units: Motor removal (FM1/FM2), transmission oil specs (SAW 80), and planetary gear repairs.

- Brake System: Service and parking brake adjustments, including brake lining wear limits (2mm minimum thickness).

- Steering System: Service for Danfoss OSPC control units and priority valves (pre-load pressure 7 bar).

- Console & Interface: Full guide to the LCD display levels, password levels 1 and 2, and software version history.

- Mast & Hydraulics: Chain adjustment for Telescopic, Hi-Lo, and Triple masts; lift/tilt speeds; and line failure safety device (LBS) operations.

Unique Reference Data

For exact part identification and system cross-referencing, this manual includes:

- Manual Ident-No: 164526 (en)

- Controller ID: 01601503

- General Series Ref: R50-00

- Lubricant Reference: STILL Ident No. 148659 (Stub axle grease)

Whether you are performing a routine battery computer reset or a full hydraulic pump overhaul, this manual delivers the specific voltages, torques, and circuit diagrams required for professional results. Keep your STILL fleet in factory-spec condition with the most informative technical guide available.

FAQ

Customer Reviews

Read what our customers say about this Still Forklift manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)