1997-2002 DAF 95XF Trucks (FT, FA, FTP, FTG, FTS, FTT, FAC, FAD) Service Manual

Service and maintenance manual covering DAF 95XF trucks (FT, FA, FTP, FTG, FTS, FTT, FAC, FAD) with detailed procedures and diagrams. Ref: DAF-95XF-Series-Truck.zip

Manual Preview

Sample pages from the 1997-2002 DAF 95XF Trucks (FT, FA, FTP, FTG, FTS, FTT, FAC, FAD) Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

1997-2002 DAF 95XF Trucks (FT, FA, FTP, FTG, FTS, FTT, FAC, FAD) Service Manual | Comprehensive Coverage This manual provides detailed technical information for DAF 95XF trucks.

- Published Technical Data: 1200 dpi establishes the maximum print output Architecture.

- Specific Operational Parameters: For optimal system function, 75.022 mm defines the cylinder bore at return point Framework.

- Integral System Specifications: Piston-pin bore diameter is 15.018 mm -- signifies the calibrated dimension Threshold.

- Operational Diagnostic Standards: The formatter board requires 64 MB for standard operation Logic.

- Fundamental Component Data: For consistent operation, 0.25 - 0.35 bar defines the differential pressure Standards.

- Universal Calibration Protocol: Crankshaft main bearing, non-driving end maintains 34.963 mm Protocol.

Professional Workshop Service Manual & Technical Specifications

DAF 95XF Trucks (FT, FA, FTP, FTG, FTS, FTT, FAC, FAD) Service Manual: 1997-2002 Field-Reference

Application-Range: All 95XF models // Year-Coverage: 1997-2002 // Application-Range: FT, FA, FTP, FTG, FTS, FTT, FAC, FAD Logic

| Service-Nexus | System-Path | Calibration-Data |

|---|---|---|

| Compressor Specs | Wabco 911 504 500 0 | 2-cylinder, water-cooled |

| Brake System | Service-Brake Valve | Knorr MB 4694 II/14119 |

| Load-Sensing Valve | Leaf-Spring Suspension | Size A: 350 mm |

| Brake Light Switch | Messmer 131 733 | Approx. 0.5 bar |

| Air Dryer | Haldex | Basic brake travel: 35-40 mm |

| Automatic Slack Adjuster | Wabco 475 010 400 0 | Setting: 8.0 bar |

Reference chapters include: INSPECTION AND ADJUSTMENT, REMOVAL AND INSTALLATION, DISASSEMBLY AND ASSEMBLY, BALANCING OF VEHICLE COMBINATIONS.

Compressor Components

This section details the compressor, including its design, specifications, and rejection criteria. It covers aspects like cylinder bore, piston ring groove height, and bearing dimensions, providing essential data for maintenance.

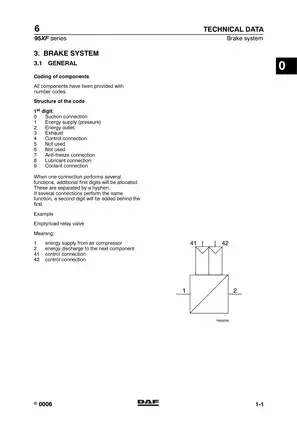

Brake System Components

Explores various brake system components such as service-brake valves, load-sensing valves, and brake-light switches. It includes application details, purpose, and operational descriptions for each part.

Brake Drum and Lining Inspection

Provides guidance on inspecting brake drums and linings, including permissible crack widths and lengths for drums, and aspects of brake linings like glazing, wear, and corrosion. It outlines procedures for reconditioning and fitting.

Automatic Slack Adjuster

Details the inspection and adjustment of the automatic slack adjuster, covering slack adjuster stroke, internal slip checks, and procedures for maintaining optimal brake performance.

Troubleshooting and Maintenance

Covers essential maintenance tasks such as air dryer filter element replacement and brake adjustment. It emphasizes correct procedures and specifications to ensure system reliability.

FAQ

Customer Reviews

Read what our customers say about this DAF Truck manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)