1958-1964 Massey Ferguson MF 65 Tractor Shop Manual – Comprehensive Maintenance, Troubleshooting & Repair Procedures

This comprehensive shop manual covers the Massey Ferguson MF 65 tractor, detailing maintenance, troubleshooting, and repair procedures for all models. Ref: SM-MF65

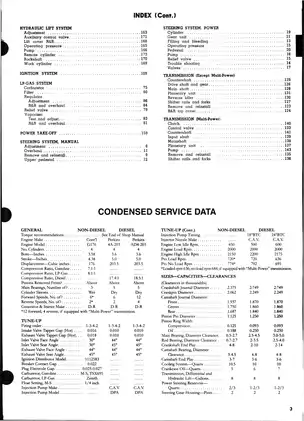

Manual Preview

Sample pages from the 1958-1964 Massey Ferguson MF 65 Tractor Shop Manual – Comprehensive Maintenance, Troubleshooting & Repair Procedures manual

Purchase & Download

Models Covered & Key Technical Specifications

Massey Ferguson MF 65 Tractor Shop Manual: Comprehensive Maintenance, Troubleshooting & Repair Procedures 1958-1964 Reference-Archive

Covers MF 65 Standard / MF 65 Hi-Arch / MF 65 Utility / MF 65 Tricycle / MF 65 Regular Diesel / MF 65 Direct Injection Diesel / MF 65 Gasoline / MF 65 LP-Gas | Repair Procedures Directory Unit.

- Approved Tolerance Values: 0.002-0.008 is the specified end play for the axle center member Margin.

- Baseline Interference Fit: For critical component seating, 0.003 is the recommended interference fit Standards.

- Verified Electrical Load: For optimal power transfer, 2300 RPM signifies the standard operating speed Architecture.

- Designated Production Rate: The governor controls engine speed, setting the idle speed at 400-450 RPM Protocol.

- Certified Imaging Specs: For engine timing accuracy, 6 degrees BTC is the specified ignition timing parameter Standards.

- Reference Clearance Data: Optimal valve stem clearance ranges from 0.0006-0.0029 inches Parameters.

Professional Workshop Service Manual & Technical Specifications

Massey Ferguson MF 65 Tractor Shop Manual: Comprehensive Maintenance, Troubleshooting & Repair Procedures 1958-1964 Reference-Archive

Product-Line: Tractor // System-Coverage: All Major Systems Logic // Service-Level: Repair Data

Comprehensively establishing procedures for the Massey Ferguson MF 65 Tractor. This manual details the tractor's systems, providing essential service information. Technical units are distributed across various sections, covering engine specifications, transmission, hydraulics, and more.

Technical Specs Overview

| Assessment-Parameter | Diagnostic-Logic | Context |

|---|---|---|

| Engine Displacement | 176-203.5 cubic inches | Engine Specifications |

| Ignition Timing | 4-6 degrees BTDC | Engine Timing |

| Fuel System | Carbureted or Diesel | Fuel Delivery System |

| Transmission Type | Dual Range, 3-Speed + Multipower | Powertrain System |

| Hydraulic System | Piston Pump, Remote Cylinder Control | Hydraulic System |

Table Position: MIDDLE

This manual outlines procedures for various maintenance and repair tasks. It covers engine disassembly, component replacement, and system adjustments. Specific sections detail the hydraulic lift system, carburetor adjustments, and electrical system testing.

Disassembly instructions are documented for engine components, including the cylinder head, pistons, and crankshaft. Wear limits are specified for critical engine parts to ensure proper operation and longevity.

System operation descriptions cover the transmission, including the dual range and Multipower units. Detailed procedures are provided for steering system maintenance and repair.

The documentation addresses the brake system, belt pulley unit, and power take-off systems, offering guidance for adjustments and overhauls.

Assembly instructions are detailed for each major component, ensuring correct reassembly and alignment. The manual also documents torque specifications for critical engine components to ensure proper vibration dampening.

Torque Context: vibration dampening

FAQ

Customer Reviews

Read what our customers say about this Massey-Ferguson Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)