1956-1964 Massey-Ferguson 35 Tractor Workshop Service Manual (383 P.)

Complete factory workshop service manual for all Massey-Ferguson 35 models including petrol, diesel, and vaporizing oil engines. Covers engine overhaul, cooling system, fuel system, and governor control with precision specifications and service procedures.

Manual Preview

Sample pages from the 1956-1964 Massey-Ferguson 35 Tractor Workshop Service Manual (383 P.) manual

Purchase & Download

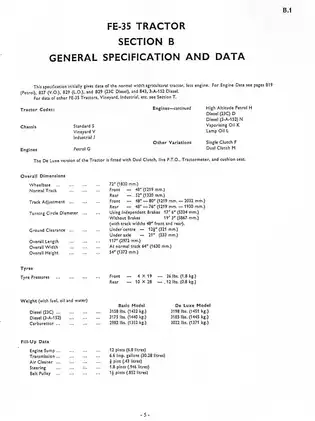

Models Covered & Key Technical Specifications

Massey-Ferguson 35 Tractor Series — 1956–1964 Technical Service Manual | Agricultural Tractor Collection.

- Calibrated Displacement Data: 2186.5 cc (133.4 cu in) is specified as the engine cylinder volume Architecture.

- Rated Fuel Tank Capacity: For agricultural operation, 94 Imperial gallons (42 litres) defines the primary fuel storage Parameters.

- Compression Ratio Specification: The 3-A-152 diesel engine requires 17.43:1 for efficient combustion chamber pressure Standards.

- Primary Power Output: Brake horsepower reaches 37.25 hp at rated engine speed Threshold.

- Transmission Fluid Volume: The gearbox reservoir controls 6.6 Imperial gallons (30.28 litres) Norms.

- Critical Bearing Torque Setting: Main bearing attachment fasteners are specified as 110–120 lbs/ft (15.21–16.59 kg.m.) Protocol.

Professional Workshop Service Manual & Technical Specifications

Essential Repair Wiring Manual: Massey-Ferguson MF35 Tractor Service Documentation

Diagnostic-Area: Comprehensive 3-cylinder diesel and petrol engine systems // Coverage-Scope: Multi-system technical framework encompassing mechanical subsystems // Technical-Scope: Factory-authorized workshop specifications including torque data and dimensional tolerances.

| Component System | Technical Category | Documentation Status |

|---|---|---|

| Engine Assembly (23C/3-A-152 Diesel, 87mm Petrol) | Powertrain Core Operations | Detailed specifications provided |

| Transmission & Rear Axle | Drive Train Mechanics | Complete dimensional data included |

| Hydraulic Lift & Mechanism | Power Control Systems | Operational parameters documented |

| Fuel System (Injection/Carburetion) | Fuel Delivery Networks | Pressure settings and filter specifications |

| Cooling System Water Jacket | Thermal Management | Thermostat and pump performance data |

| Electrical Distribution | Power Generation & Starting | Charging and ignition specifications |

Providing a structural breakdown of the document, the manual comprehensively addresses foundational engine architecture alongside transmission behavior, further encompasses hydraulic lift functionality, and clarifies fuel system operation while simultaneously covering electrical system configuration and cooling mechanisms. Assembly instructions are detailed for connecting rod installation, hydraulic schematics are included for lift mechanism circuits, steering component information is provided for front axle adjustment, inspection guidelines are provided for bearing clearances, and alignment specifications are included for transmission case mounting. The manual establishes a logical framework connecting crankshaft journal specifications to main bearing cap assembly, progresses through camshaft timing procedures, and documents piston ring gap verification within cylinder liner bore measurement standards, then addresses rocker shaft pedestal alignment before concluding with flywheel run-out examination protocols.

The documentation includes torque specifications for fastener fatigue prevention across all major engine bolts, transmission case studs, and hydraulic system connections to ensure durable service life.

Document contents: Sections address engine removal and replacement procedures, cylinder head assembly with valve seat reconditioning, crankshaft bearing maintenance, piston assembly alignment, timing cover installation, and fuel pump integration. Technical data encompasses bore diameters ranging from 87mm petrol variants through 23C diesel (84.137mm) to 3-A-152 diesel engines (91.44mm), stroke measurements from 92mm to 127mm displacement variants, and compression ratios spanning 6.0:1 petrol through 17.43:1 diesel configurations. Complete tightening torque tables reference forces from 2.5 Ib./ft. through 120 Ib./ft. across component categories. Dimensional tolerances specify bearing fits to ±.0001" increments and oil seal engagement specifications. The cooling system section documents thermostat opening temperatures (58-95°C range), water pump impeller clearances (0.080-0.090"), and radiator bypass valve operation. Fuel system coverage delineates carburetor jet settings, injection pump timing at T.D.C. alignment marks, injector nozzle pressure (120-130 atmospheres), and feed pump delivery capacity (3.95-5.35 gallons per minute). Governor control mechanisms are detailed for load regulation and speed maintenance functions. Air cleaner service intervals prescribe daily oil bath refilling in standard conditions with increased frequency for dusty environments. Crankcase ventilation describes breather tube routing and canister filter element replacement. Electrical specifications reference battery capacities (38-43 amp-hour ratings), dynamo output characteristics (C39P2 type, 1.72x engine speed), and starter motor engagement parameters (distance 1.563", teeth count 113-115). Front axle geometrics include spindle bushing tolerances, hub bearing clearances, and steering drag link alignment procedures. Rear axle documentation encompasses crown wheel ratio (6.16:1), differential bearing end float (0.002-0.008"), and half-shaft collar positioning. Power take-off shaft configuration specifies spline dimensions (6 splines, major/minor diameters 1.374/1.098"), slot groove depth (0.365-0.379"), and ground speed coupling backlash (0.003-0.007"). The hydraulic system section illustrates pump displacement (2.8-3.333 gallons per minute), relief valve nominal setting (2,500 Ib. sq. in.), lifting capacity tables (ranging 1,270-4,800 lbs depending on tractor variant), and cylinder bore specifications for early/late production versions. Timing gear backlash ranges (0.003-0.006" camshaft, 0.012-0.018" lubricating oil pump) define acceptable wear limits. Service tooling recommendations reference specialized extractors, bearing pullers, and bushing reamers for precision maintenance. The manual encompasses five sections spanning 175+ pages of factory documentation.

FAQ

Customer Reviews

Read what our customers say about this Massey-Ferguson Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)