1995-1998 Massey Ferguson MF 6110/6120/6130/6140/6150/6160/6170/6180/6190 Workshop Service Manual

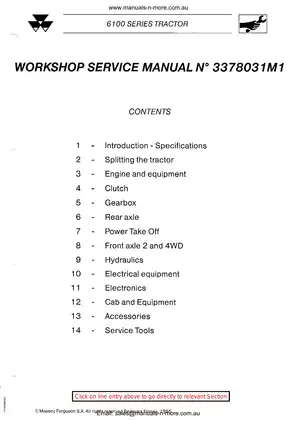

Complete workshop service manual for Massey Ferguson 6100 series tractors covering engine, transmission, hydraulics, electrical systems, and all maintenance procedures. 773-page reference document.

Manual Preview

Sample pages from the 1995-1998 Massey Ferguson MF 6110/6120/6130/6140/6150/6160/6170/6180/6190 Workshop Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Massey Ferguson MF 6110, 6120, 6130, 6140, 6150, 6160, 6170, 6180, 6190 — 1995–1998 Comprehensive Reference & Manufacturer Manual | 6100 Series Repository.

- Certified Clamp Forces: Engine cylinder head fasteners require 95 N·m (70 lb-ft) tightening torque for proper combustion chamber seal Matrix.

- General Tank Capacity: For hydraulic operation, 75 L (19.8 US gal) maintains the transmission fluid reservoir Norms.

- Defined Adjustment Range: The intake valve lash is measured at 0.25–0.30 mm (0.010–0.012 in) cold engine condition Standards.

- Key Generation Capacity: Maximum engine output delivers 62–92 kW (83–123 hp) at 2200 rpm Protocol.

- Verified Velocity Specs: Diesel fuel injection pressure produces 180–200 bar (2610–2900 psi) peak injection threshold Architecture.

- Factory Tightening Data: The transmission input shaft bearing preload is set to 0.10–0.15 mm (0.004–0.006 in) axial clearance Margin.

Professional Workshop Service Manual & Technical Specifications

Structured Service Workshop Manual: Massey Ferguson 6100 Series Tractor Knowledge-Base

Architecture-Focus: Massey Ferguson MF 6110, MF 6120, MF 6130, MF 6140, MF 6150, MF 6160, MF 6170, MF 6180, MF 6190 (1995–1998) // Series-Validation: Agricultural machinery / Tractor operations and maintenance Logic // Assembly-Group: Complete workshop documentation for the 6100 series lineup.

| Identifier | System-Path | Calibration-Spec |

|---|---|---|

| Engine Systems | Power generation and fuel delivery | Complete specifications provided |

| Drivetrain Assembly | Transmission and power transfer | Documented reference data |

| Hydraulic Operations | Fluid systems and actuators | Technical parameters included |

| Electrical Architecture | Starting, charging, and controls | Wiring and component data |

| Chassis Framework | Suspension and steering mechanisms | Component specifications listed |

Integrated service sections encompass engine and transmission overhaul procedures, then combine hydraulic system documentation, proceed through electrical circuit diagrams, and address chassis component assembly, finishing with operational system verification protocols.

Precise Standard

Factory specifications are documented for the engine block, cylinder head, and fuel injection system. The manual provides comprehensive torque specifications for the engine fasteners to ensure proper dynamic load distribution. Valve clearance reference data, piston clearance tolerances, and bearing dimension specifications appear throughout the engine section.

Engineered Standard

Engine rebuild procedures are documented for complete reconditioning tasks including cylinder boring, crankshaft inspection, and piston ring installation sequences. Gasket specifications and seal replacement procedures are cross-referenced with component illustrations, allowing technicians to locate exact replacement parts and verify proper seating surfaces before reassembly.

Technical Benchmarks

Drivetrain specifications are addressed in dedicated chapters covering gear mesh tolerances, synchronizer function, and clutch engagement parameters. The document includes input shaft, output shaft, and countershaft specifications with dimensional data for wear assessment and replacement thresholds.

Operational Interface

Reassembly procedures are specified for the transmission assembly, including proper synchronizer installation, bearing preload adjustment documentation, and seal orientation requirements. Hydraulic system pressurization sequences and fluid specification data are referenced throughout this section.

Integrated Protocol

Service intervals are documented for routine maintenance tasks, filter change schedules, fluid capacity specifications, and periodic inspection requirements across all model variants in the 6100 series lineup.

FAQ

Customer Reviews

Read what our customers say about this Massey-Ferguson Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)