1978 Yamaha Chappy LB2/LB2M Service Manual (129 Pages)

Complete 50cc minibike service documentation covering engine overhaul, carburetion, chassis maintenance, and electrical systems. Specifications include compression ratios, torque settings, and detailed repair procedures for all major components.

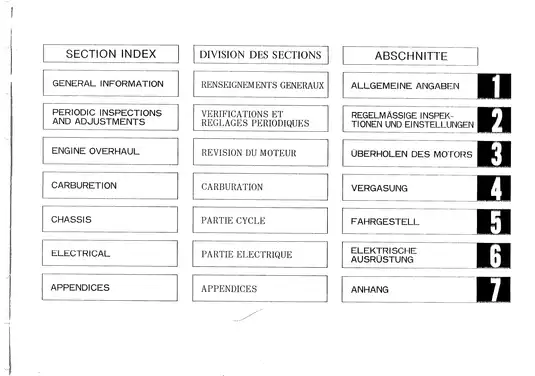

Manual Preview

Sample pages from the 1978 Yamaha Chappy LB2/LB2M Service Manual (129 Pages) manual

Purchase & Download

Models Covered & Key Technical Specifications

Yamaha LB2 / LB2M — 1978 Specialized Detailed Documentation Library.

- Measured Footprint Data: 1,585 mm length and 1,050 mm wheelbase is set to the overall vehicle dimensions Requirements.

- Established Imaging Specs: The 49 cc engine displacement specifies a single-cylinder, two-stroke, air-cooled configuration Threshold.

- Factory Tightening Data: Spark plug torque yields 2.5 m-kg (18 ft-lb) as the fastener specification Mapping.

- Integral Gap Specs: The crankshaft assembly width reaches 37.990–37.995 mm for proper bearing clearance Configuration.

- Operational Power Draw: 6V, 4 Amperes-heure — dictates the electrical system energy storage Benchmarks.

- Critical Component Weight: Fuel tank capacity produces 3.5 liters (0.92 US gallons) as the fuel reserve Range.

Professional Workshop Service Manual & Technical Specifications

Detailed Technical Reference Manual: Yamaha LB2/LB2M 50cc Minibike (1978) Logic-Archive

Component-Focus: LB2 (1978), LB2M (1978) // Unit-Designations: Engine, transmission, and chassis systems Logic // Technical-Scope: Complete service and maintenance documentation including specifications, inspection procedures, and assembly sequences.

| Document Category | Coverage Scope | Reference Information |

|---|---|---|

| Engine Systems | Ignition timing, carburation, and combustion chamber procedures | Complete specifications provided |

| Transmission & Reduction | Primary and secondary drive mechanisms with gear ratios | See Chapter B specifications |

| Chassis & Suspension | Wheel bearings, brake assemblies, and steering head data | Documented across Chapter 5 sections |

Systematizing the service groups into engine overhaul, periodic maintenance, transmission adjustment, chassis inspection, electrical diagnostics, and troubleshooting guide, the document identifies crankshaft deflection limits, establishes clutch lever freeplay tolerance, and addresses steering head bearing adjustment with integrated schematic diagrams. Cooling system maintenance is addressed in the carburetor and air cleaner sections, fuel system servicing follows lubrication intervals, and reed valve assembly inspection requires reference measurement data. Testing requirements are specified for ignition point gap, battery specific gravity, and charging system output across engine speed ranges. Clearance measurements are addressed for piston-to-bore fit, connecting rod end play, and transmission gear backlash.

The manual documents torque specifications for fastener fatigue prevention, including spark plug installation (2.5 m-kg), cylinder head attachment (1.0 m-kg), and drivetrain component assembly (4.5–5.5 m-kg range). Specifications encompass displacement (49 cc), bore and stroke (40.0 × 39.7 mm), compression ratio (5.43:1 or 6.6:1 variant), and clutch friction plate thickness limits (3.5 mm new, 3.2 mm minimum). Reed valve bending tolerance is documented as 0.3 mm maximum deflection. Carburetor data includes jet sizing, needle jet positioning, float level adjustment (22.0–22.5 mm ±1 mm), and idling speed reference (1,350 ± 100 rpm). Air/fuel mixture adjustment procedures reference pilot screw positioning and jet needle clip location. Autolube pump stroke length ranges from 0.15–0.20 mm (minimum) to 0.70–1.02 mm (maximum) depending on model variant. Tire pressure specifications are documented for front (1.2 kg/cm²) and rear (1.5 kg/cm²) application. Electrical system data includes ignition coil spark gap (6 mm minimum at 500 rpm), contact point gap (0.3–0.4 mm), and battery charge specifications (6V, 4Ah capacity). Lighting output and charging coil resistance values are provided for multiple market variants (Germany, Austria, Sweden, Denmark, France, Switzerland).

Precisely establishing the document's technical scope, the manual includes wiring diagrams for regional variants, cable routing schematics, and component identification drawings. Circuit diagrams reference switch positions, battery connections, and harness assembly orientation. Troubleshooting guidance addresses compression pressure diagnosis, spark generation faults, fuel delivery blockage, and carburetor operation anomalies. The document incorporates French and German translations of all English-language content for multi-market service support. Maintenance intervals table specifies inspection frequency at 500 km initial, 1,500 km, 3,000 km, and 6,000 km service points. Lubrication schedule references SAE 10W-30 Type "SE" motor oil selection, lithium soap grease application, and medium-weight wheel bearing grease specification. Component inspection procedures detail cylinder bore measurement technique, piston ring end gap verification, crankshaft runout assessment, and clutch shoe lining thickness evaluation (2.5 mm new, 2.0 mm replacement limit). Ignition timing adjustment method uses dial gauge apparatus with referenced top-dead-center piston position and flywheel rotation sequence.

FAQ

Customer Reviews

Read what our customers say about this Yamaha Minibike manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)