Professional Polaris Indy 500 Snowmobile Service Manual (2000) 412 Page Volume | Shop Standards

Manual Preview

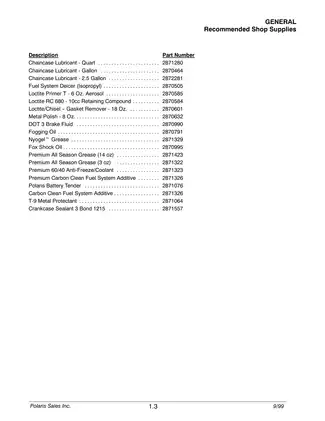

Sample pages from the Professional Polaris Indy 500 Snowmobile Service Manual (2000) 412 Page Volume | Shop Standards manual

Purchase & Download

Models Covered & Key Technical Specifications

-

POLARIS INDY 500 SERIES (2000) | Series: GEN II / S00-Series

-

Archive includes: Indy 500 | 500 Classic | Classic Touring | WideTrak LX | 500 XC | 500 SKS | 500 XC SP 45th Anniv. | 500 RMK

-

Model Identity: Polaris Indy 500 / 2000 / GEN II Chassis / Liquid-Cooled Twin

-

Archive includes: S00SB4BS / S00SD4BS / S00ST4BS / S00SU4BS / S00SB5AS / E00SS5AU / S00SP5CS / S00SR5AS

-

Power & Drive Core: Fuji 488cc Piston Port (Standard) / Domestic 500cc Case Reed (XC/SP) | 7000-8500 RPM | P-85 Drive Clutch | VM34SS to TM38 Mikuni

-

Technical Systems: P-85 Variable Transmission | Liquid Cooling System | CDI Ignition | Hydraulic HPB or Mechanical Disc Brakes

-

Essential Benchmarks: Ignition Timing: 28° BTDC (Fuji) / 12°-26° BTDC (Domestic) | Spark Plug Gap: 0.028" (0.7mm) | Piston Clearance: .0035"-.0049" (Fuji) / .0045"-.0063" (Domestic)

-

Capacities & Consumables: Fuel: 11.0-12.0 gal | Oil: 2.0-3.0 qt | Coolant: 3.0-5.0 qt | Chaincase: 7-11 fl.oz (Standard) / 20 fl.oz (WideTrak)

Professional Workshop Service Manual & Technical Specifications

POLARIS INDY 500 SERIES (2000) Service Manual

This master-level technical guide provides the essential data required for precision maintenance of the 2000 liquid-cooled 488cc and 500cc twin-cylinder platforms. Snowmobile engine longevity and track-drive efficiency depend on meeting strict factory benchmarks for timing, torque, and clearance. Professionals utilizing these protocols eliminate the risks associated with diagnostic guesswork and ensure secondary systems like the XTRA suspension and hydraulic HPB brakes operate at peak safety.

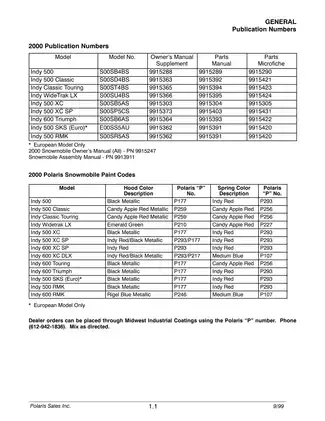

Active Model Coverage & Configuration Data

Actionable repair data in this volume covers the following primary Gen II and specialized chassis variants for the 2000 model year:

- Indy 500 / Indy 500 Classic: S00SB4BS / S00SD4BS

- Indy Classic Touring / WideTrak LX: S00ST4BS / S00SU4BS

- Indy 500 XC / 500 XC SP: S00SB5AS / S00SP5CS

- Indy 500 SKS (European) / 500 RMK: E00SS5AU / S00SR5AS

- Series Inclusions: Coverage extends to 45th Anniversary editions and high-utility liquid-cooled configurations utilizing Fuji and Domestic case-reed powerplants.

Technical Document Logistics

- File Format: High-Resolution PDF

- Total Page Count: Approximately 412 Pages

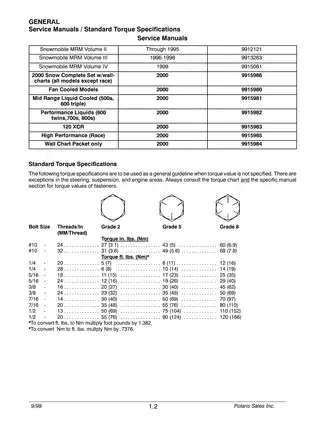

- Publication Code: PN 9915981 (Mid-Range Liquid Cooled 500/600)

- Official Revision Date: September 1999

Operational Investment & Equipment ROI

- Avoid "Component Swapping": Use exact electrical resistance values for stators and CDI units to prevent unnecessary part costs.

- Maintain Critical Clearances: Precision Piston-to-Cylinder gaps (0.0035" - 0.0063") prevent premature seizure and power loss.

- Protect Drive Components: Strict clutch offset and alignment specifications ensure maximum drive belt life and torque transfer.

- Safety Protocol Enforcement: Follow torque-to-yield sequences on steering and suspension fasteners to prevent mechanical failure during high-speed operation.

Integrated Technical Data Matrix

| Service Point | Benchmark Target | Maintenance Benefit |

|---|---|---|

| Piston Clearance | 0.0035" - 0.0049" (Fuji) | Optimized compression / Seizure prevention |

| Ignition Timing | 28° BTDC @ 3000 RPM (Fuji) | Peak combustion efficiency / Detonation control |

| Spark Plug Gap | 0.028" (0.7 mm) | Reliable cold starting / Consistent spark arc |

| Fuel Requirement | 87 Non-Oxy / 89 Oxygenated | Engine cooling / Pre-ignition prevention |

| Clutch Torque | 60-65 ft. lbs. (Flywheel) | Drive system stability / Safety |

| HPB Fluid Type | DOT 3 Brake Fluid | Fade resistance / Hydraulic integrity |

High-Resolution Schematic Depth

Visual protocols include ultra-high-resolution wiring diagrams for specialized 45th Anniversary CDI systems and standard pulse-timing setups. Detailed thread-paths for mechanical brake linkages and hydraulic hose routing for LC (Liquid Cooled) calipers ensure error-free reassembly. Exploded views cover P-85 drive and driven clutch internals, documenting every shim, roller, and spring position for precise CVT tuning.

Electrical & System Logic Diagnostics

- Ignition Troubleshooting: Systematic testing for the CDI control box, exciter coils, and pulser (trigger) coils using dedicated Ohms (Ω) resistance values.

- Speed Control Assurance: Functional logic tests for the two-series throttle safety switches to prevent "runaway" engine conditions.

- TPS Calibration: Full procedures for the Throttle Position Sensor (Domestic Engines) with a target range of 3.70 to 4.50 Volts at Wide Open Throttle (WOT).

- Cooling Integrity: Pressure testing guidelines for the surge tank and radiator cap (LR9/LR2 regulators) to verify system circulation and boil-over protection.

Primary Service Chapters

- Chapter 1: General Information & Detailed Model Specifications

- Chapter 2: Maintenance, Tune-Up, and Off-Season Storage Protocols

- Chapter 3: Engine Overhaul (Fuji 488cc / Domestic 500cc Case-Reed)

- Chapter 4: Fuel Systems (Mikuni VM34SS, VM38SS, and TM38 Service)

- Chapter 5: Clutches & Drive Belts (P-85 System Calibration)

- Chapter 6: Body, Steering, and IFS Front Suspension Alignment

- Chapter 7: Rear Suspension (XTRA-10, XTRA-12, and XTRA-Lite tuning)

- Chapter 8: Brakes & Final Drive (Chaincase, Gears, and Hydraulic Service)

FAQ

Customer Reviews

Read what our customers say about this Polaris Snowmobile manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)