1965-1985 Detroit Diesel Series 53 Service Manual

Complete service procedures for 2-53, 3-53, 4-53, 6V-53 and 8V-53 engines. Full coverage of maintenance, tune-up, troubleshooting and overhaul operations.

Manual Preview

Sample pages from the 1965-1985 Detroit Diesel Series 53 Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Detroit Diesel Series 53 (2-53, 3-53, 4-53, 6V-53, 8V-53) — 1965–1985 Professional Industrial Compendium | Series 53 Engine Kit.

- Calibrated Rotation Data: Two-stroke cycle engines establish the fundamental operating principle at maximum 3200 rpm rated speed Architecture.

- Rated Cylinder Bore: For optimal precision engineering, 3.875 inches (98.4 mm) defines the piston diameter Margin.

- Published Stroke Length: The connecting rod travel achieves 4.5 inches (114.3 mm) total reciprocating distance Protocol.

- Authorized Displacement Range: The 2-53 model supports 106 cubic inches (1.74 L) minimum to 8V-53 model provides 424 cubic inches (6.95 L) maximum Norms.

- Maximum Compression Ratio: Standard engines establish 17:1 compression ratio while turbocharged models achieve 21:1 for enhanced combustion efficiency Bounds.

- Documented Fuel Injection System: Unit fuel injectors govern precise timing with multiple cam profiles available for low-velocity or high-velocity combustion chamber configurations Topology.

Professional Workshop Service Manual & Technical Specifications

In-Depth Service Diagnostic Manual: Detroit Diesel Series 53 Engines Service Documentation

Architecture-Focus: 2-53, 3-53, 4-53, 6V-53, 8V-53 (1965–1985) // Maintenance-Category: Engine systems servicing and component management // Operational-Framework: Comprehensive service and maintenance protocols with technical specifications.

| Documentation Section | Coverage Area | Reference Materials |

|---|---|---|

| Engine Assembly & Components | Cylinder block, crankshaft, pistons, connecting rods, liners | Complete specifications provided |

| Fuel & Air Systems | Fuel injection, air intake, governors, blower assemblies | System data documented |

| Lubrication & Cooling | Oil distribution, bearing specifications, coolant passages | Full system diagrams included |

| Electrical & Power Systems | Starting motors, generators, protective systems, torque converters | Component reference data |

| Maintenance Procedures | Preventive servicing, inspection intervals, storage protocols | Operational guidelines documented |

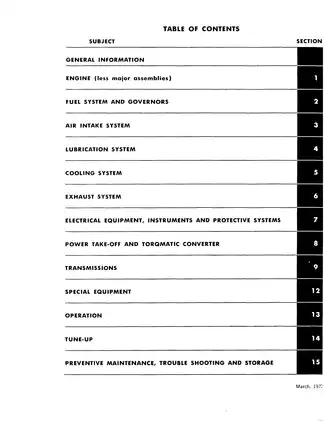

Integrated service sections encompass the removal and installation of cylinder block assemblies, including detailed guidance for crankshaft and connecting rod bearing maintenance. The manual documents fuel system architecture, covering governors, fuel pumps, and injector operating mechanisms. Air intake system content addresses blower drives, accessory configurations, and scavenging air pathways.

Advanced Threshold

Lubrication system procedures include oil pump specifications and cooling system interactions throughout the engine structure. Exhaust valve maintenance receives comprehensive coverage, with instructions for valve guide installation, seat insert reconditioning, and spring pressure documentation. The manual provides detailed information on piston and ring servicing, including measurements for piston-to-liner clearance and specifications for bushing installation in connecting rods.

Strategic Protocol

Crankshaft servicing content encompasses journal measurements, bearing shell thickness specifications, and procedures for identifying cracks through magnetic particle inspection methods. Power take-off and transmission coupling information documents flexible coupling operation and clutch pilot bearing maintenance. The manual includes accessory drive configurations for both gear-driven and belt-driven equipment mounted to the camshaft and balance shaft gears.

Advanced Benchmarks

Engine timing procedures reference gear train alignment using marked timing symbols on crankshaft, camshaft, and idler gears. Balance weight positioning and front cover assembly instructions are documented with corresponding torque specifications. The manual documents torque specifications for the crankshaft fasteners to ensure proper component alignment retention.

Operational Standard

Cylinder head removal and installation sequences provide mounting flange specifications and compression gasket placement guidance. Rocker arm and valve operating mechanism servicing includes cam follower inspection procedures and push rod spring load testing methodology. Valve spring testing procedures establish opening pressure requirements for both two-valve and four-valve cylinder head assemblies.

Engineered Parameters

Bearing clearance specifications and crankshaft thrust washer dimensions are documented throughout the manual for in-line and V-type engine configurations. Main bearing bore machining tolerances and camshaft bearing installation positioning details support precision engine rebuilding. The documentation references oil circulation passages in the block, connecting rod drilled passages, and seal ring installation locations for comprehensive system understanding.

Reference chapters include shop notes addressing magnetic particle crack detection, plastic strip bearing clearance measurement techniques, and line boring specifications for cylinder block main bearing bores. Troubleshooting sections document causes of abnormal wear conditions and guidance for identifying contamination sources affecting bearing service life.

FAQ

Customer Reviews

Read what our customers say about this Detroit Diesel Engine manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)