2001-Later Takeuchi TL126 Excavator Parts Catalog (207 P.)

ISUZU A-4JB1PAA10 engine specifications and component assembly. OEM parts list covering hydraulic systems, control valves, and travel motors. Book No. PT5-101Z5

Manual Preview

Sample pages from the 2001-Later Takeuchi TL126 Excavator Parts Catalog (207 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Takeuchi ISUZU TL126 (PT5-101Z5) — 2001 and Later Advanced Systematic Vault | TL126 Series Division.

- Approved Volume Data: 4.566 L (278.6 cu in) is measured at the engine displacement capacity Bounds.

- Baseline Charge Quantity: For optimal hydraulic performance, 85 L (22.4 US gal) maintains the main system reservoir Topology.

- Measured End Play: The main hydraulic pump delivers 40 cc/rev displacement configuration Matrix.

- Verified Cooling Specs: Operating coolant capacity represents 12.5 L (3.3 US gal) at thermal limit Standards.

- Certified Mass Specs: Total operating weight reaches 12,600 kg (27,778 lb) at full capacity Margin.

- Reference Twist Specifications: Maximum engine torque is rated at 265 N·m (195 lb-ft) at 2000 rpm Protocol.

Professional Workshop Service Manual & Technical Specifications

OEM-Grade Documentation Manual: Excavator Official Takeuchi ISUZU TL126 Excavator (2001 and Later) Maintenance & Repair Manual - OEM-Grade Procedures System-Standards

Coverage-Scope: ISUZU TL126 (2001 and later) // Technical-Scope: Hydraulic, Undercarriage, and Engine Systems // Technical-Domain: Complete component reference documentation with part numbers and assembly configurations.

| System Category | Components Documented | Documentation Type |

|---|---|---|

| Undercarriage Assembly | Track rollers (rubber/steel), front idler, track adjuster, travel device, crawler belt | Complete parts diagrams and part number reference |

| Engine & Electrical | ISUZU A-4JB1PAA10 engine, cooling systems, wiring harness, control box, battery | Detailed component breakdown and interconnection data |

| Hydraulic Systems | Control valve, pilot valves, sub valve, arm cylinder, bucket cylinder, travel motors, hydraulic pump | Full assembly diagrams across four serial number ranges |

| Structural & Cab | Main frame, arm stopper, floor frame, seat options, front door, side window, canopy, heater | Component listing with specification references |

The manual presents information on undercarriage systems and track components, documents hydraulic piping and pump assemblies, and includes control valve subcategories for arm and bucket operation. Wiring diagrams are provided for electrical system integration, fuel system procedures are documented for engine-related maintenance, and timing procedures are documented for the ISUZU A-4JB1PAA10 engine installation. Adjustment procedures are detailed for track tension and control systems, with complete parts catalogs for both rubber and steel crawler configurations.

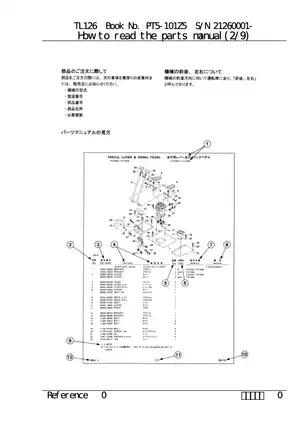

Service procedures are grouped by major mechanical assembly, with separate sections addressing the main frame and control lever systems, hydraulic tank and fuel tank configuration, and full coverage and cab component options. The document includes wiring diagrams for the control box and electrical harness assembly, along with reference data for decals and painted color finish options. Proper protocol for reading exploded-view diagrams is included in the initial sections to support accurate parts identification and procurement.

The manual documents torque specifications for fastener assembly to ensure proper mechanical engagement and structural integrity across all component groups.

| Chapter or Section | Primary Focus | Resource Type |

|---|---|---|

| How to Read the Parts Manual | Diagram interpretation and part number cross-reference methodology | Reference guide with visual examples |

| Undercarriage & Track Systems | Roller assemblies, idler mechanisms, adjuster cylinders, travel motors | Parts catalog with quantity and serial number tracking |

| Engine Reference Materials | ISUZU A-4JB1PAA10 engine components and mounting configuration | Engine-specific diagram set for 40+ pages |

| Hydraulic Devices & Controls | Multi-stage valve assemblies, cylinder specifications, pump construction details | Technical parts breakdown across four pump variant configurations |

| Cab & Operator Environment | Seating, door hinges, window mechanisms, heater circuit, noise absorbent materials | Complete parts listing with material options (rubber/steel/UV-resistant) |

| Decal & Identification | Safety markings, operational warnings, color finish specifications | Decal part numbers and application reference |

| Numerical Index | Cross-reference of all 1000+ part numbers with page location | Complete searchable parts reference |

FAQ

Customer Reviews

Read what our customers say about this Takeuchi Excavator manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)