1995 Fiatallis / Fiat-Hitachi FX250 Operation and Maintenance Manual

Covers FX250 hydraulic excavator models with procedures for engine operation, maintenance schedules, and Cummins 6BTA5.9C diesel specifications. Complete technical service guide with ETS electronic control documentation.

Manual Preview

Sample pages from the 1995 Fiatallis / Fiat-Hitachi FX250 Operation and Maintenance Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Fiatallis FX250 Hydraulic Excavator — 1995 Consolidated Portfolio Mechanical Kit.

- Approved Power Draw: The Cummins 6BTA5.9C engine is measured at 169 hp (126 kW) maximum rated output Architecture.

- Factory Ambient Limits: For optimal excavator operation, engine temperature maintenance requires 82–93°C (180–200°F) coolant range Norms.

- Verified Feed Speed: Hydraulic pump displacement produces 62 cc/rev (3.78 cu in/rev) at 2100 rpm system Bounds.

- Designated DPI Rating: The main relief valve requires 210 bar (3045 psi) maximum system pressure setting Topology.

- Essential Volume Data: Hydraulic tank capacity reaches 350 L (92.5 US gal) for complete system circulation Matrix.

- Operational Circuit Specs: Engine displacement measures 5.9 L (360 cu in) with 24:1 compression ratio specification Standards.

Professional Workshop Service Manual & Technical Specifications

Certified Workshop Shop Manual: Excavator FIATALLIS / FIAT-HITACHI FX250 Hydraulic Excavator (1995) – Operation and Maintenance Manual, 169 HP Cummins 6BTA5.9C Engine, ETS Electronic Control, Technical Specifications & Service Guide Maintenance-Registry

Technical-Domain: FIATALLIS FX250, FIAT-HITACHI FX250 (1995) // Model-Designation: Hydraulic Excavator Operations / Cummins Engine Systems Logic // Series-Validation: 1307-page comprehensive manual with 169 HP engine and electronic control systems.

| Assessment-Element | Rating | Calibration-Spec |

|---|---|---|

| Engine Documentation | Complete | Cummins 6BTA5.9C specifications included |

| Hydraulic Systems | Documented | Full system architecture and components |

| Electronic Controls | Comprehensive | ETS control system information provided |

| Operator Functions | Detailed | Control and operation procedures documented |

| Service Data | Complete | Maintenance schedules and component specs |

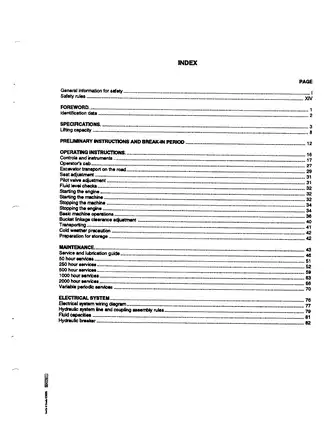

Repair data is categorized into operation, maintenance, and diagnostic sections that encompass the engine assembly, hydraulic transmission system, control mechanisms, structural framework, and electrical architecture. The document organizes service information covering engine diagnostics, hydraulic fluid management, transmission service data, brake system procedures, and electrical component reference materials.

Comprehensive Standard

OEM guidelines are included for the Cummins 6BTA5.9C diesel engine, which powers the FX250 excavator platform. The manual provides detailed specifications for engine operation, including fuel system requirements, cooling circuit parameters, and ignition timing references. Engine maintenance intervals are documented with component identification and service point locations throughout the engine block, cylinder head assembly, and accessory drive systems.

Technical Benchmarks

Transmission service information covers the hydraulic drive systems, pump specifications, valve configurations, and fluid circulation pathways. The document includes component identification for the main control valve assembly, auxiliary hydraulic circuits, and pressure relief systems. Reference data for hydraulic fluid grades, change intervals, and filtration specifications are provided to guide maintenance planning.

Diagnostic Parameters

The manual includes electronic control system documentation for the ETS (Electronic Transmission System) control module. Control signal flow diagrams, sensor location references, and electrical connector specifications are documented. Troubleshooting reference data identifies symptom-to-component relationships for electrical system failures and control unit diagnostics.

Modular Parameters

Structural and frame component information is documented, including boom and arm configurations, linkage pivot points, and attachment system specifications. The manual provides identification data for wear components, bushing locations, and structural inspection reference points for the hydraulic cylinders and actuator systems.

Precise Logic-Path

The document includes wiring diagrams for the primary electrical circuits, alternator output specifications, battery interconnection routing, and starter motor integration. Electrical system components are referenced with terminal identification and circuit protection details. The manual documents torque specifications for fastener assemblies to ensure proper mechanical assembly, including frame connection points, hydraulic adapter fittings, and engine mounting interfaces.

FAQ

Customer Reviews

Read what our customers say about this Fiat-Allis Excavator manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)