1999 Cub Cadet Series 3000 Models 3165/3185/3186/3205/3225 Service Manual (134 P.)

Series 3000 garden tractor with hydrostatic drive, power steering cylinder removal, BDU-21L transmission, and hydraulic system procedures. Manual 770-10227.

Manual Preview

Sample pages from the 1999 Cub Cadet Series 3000 Models 3165/3185/3186/3205/3225 Service Manual (134 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Cub Cadet Series 3000 Models 3165, 3185, 3186, 3205, 3225 — 1999 Advanced Systematic Digital Database Archive | 3000 Series Repository.

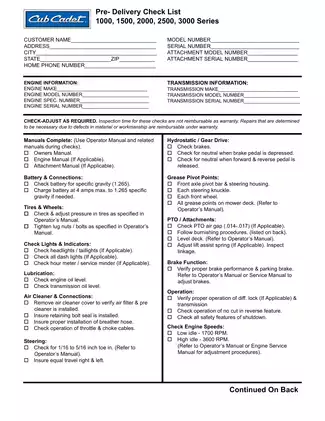

- Prescribed Charge Quantity: 4.5 gallons (17.0 L) is designed for the fuel storage tank Bounds.

- Standard Alignment Specs: For tire installation, 16" × 7.5" front and 24" × 10.5" rear tires are configured at operational specifications Topology.

- Maximum Power Framework: 1700 RPM low idle to 3600 RPM high idle indicates the engine speed operating envelope Matrix.

- System Throughput Data: The auxiliary implement pump provides 1.5 gpm flow rate at 500 PSI control pressure, reaching 3200 RPM at peak performance Standards.

- Calibrated Gross Dimensions: The turning radius requires 27 inches for standard maneuverability margin under full lock Margin.

- Nominal Capacity Limits: Forward speeds reach 0–7 MPH while reverse operation provides 0–4 MPH for safe equipment Protocol.

Professional Workshop Service Manual & Technical Specifications

Precision Specification Shop Manual: Tractor Cub Cadet Series 3000 Models 3165 3185 3186 3205 & 3225 - Comprehensive Garden Tractor Service Manual 1999 Standards-Vault

Technical-Benchmarks: Series 3000, Models 3165, 3185, 3186, 3205, 3225 (1999) // Unit-Designations: Hydrostatic drive system / Multi-cylinder engine platforms // Asset-ID: Service documentation with 18 sections covering complete tractor systems.

| Metric | Value | Calibration-Spec |

|---|---|---|

| Total Pages | 137 pages | Complete documentation |

| Section Coverage | 18 technical modules | All major systems included |

| Engine Options | B&S Twin, Kohler V-Twin, Kawasaki | Multiple configurations documented |

| Transmission Type | BDU-21L Hydrostatic | Full schematic specifications provided |

| Hydraulic System | Power steering, lift control | Pressure test procedures included |

The service manual covers pre-delivery inspection protocols and engineering updates for 1999 production, establishes detailed procedures for component removal and reinstallation, documents transmission inspection and reassembly methodology, and provides electrical schematic diagrams for all engine variants.

Component locations are identified for the fender assembly, power steering cylinder, center lift mechanism, and pump adapter integration. Service procedures are documented for the hydraulic steering pump, steering control valve disassembly, and auxiliary pressure testing operations. Calibration requirements are specified for neutral control adjustment, hydrostatic transmission pressure measurement, and charge pump verification. Electrical system documentation covers wiring harness configurations for Briggs & Stratton, Kohler, and Kawasaki engine platforms across ignition, starting, charging, lighting, and PTO circuit sequences. Suspension service documentation covers brake assembly maintenance, wheel hub procedures, and differential lock actuator operation.

The manual documents torque specifications for steering control end cap fasteners, differential housing bolts, transmission plate hardware, and brake mounting components to ensure proper fastener integrity.

System overview addressing the BDU-21L transmission auxiliary implement circuit (1.5 gpm rated flow at 500 PSI), charge pump relief valve configuration, and closed-loop hydraulic architecture. The documentation includes assembly procedures for charge pump installation, shaft seal replacement protocols, bypass valve servicing, and charge check valve inspection methodology. Major repair sections establish disassembly sequences for center section removal, motor and pump cylinder block separation, and swashplate assembly extraction. Reassembly protocols specify piston installation with retention bands, cylinder block running surface flatness requirements (0.0004 inch maximum removal allowance), and control shaft end play measurement between 0.020 and 0.060 inches. Minor repair guidance covers lip seal installation with shaft wrapping protection, bearing spacer washer positioning, and thread locker application for differential housing fasteners.

FAQ

Customer Reviews

Read what our customers say about this Cub Cadet Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)