1979 Cub Cadet Tractors 86-1650 Service Manual (146 P.)

Cub Cadet service documentation covering models 86 through 1650 with complete transmission, hydrostatic drive, and differential specs. Includes clutch, brake, and PTO adjustment procedures with torque data GSS-1464.

Manual Preview

Sample pages from the 1979 Cub Cadet Tractors 86-1650 Service Manual (146 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

International Cub Cadet 86, 108, 109, 128, 129, 149, 169, 800, 1000, 1200, 1250, 1450, 1650 — 1979 Integrated Industrial Manual | Series Repository.

- Published Assembly Gap: The single dry disc friction assembly is established at 4-1/2 inches diameter specification Matrix.

- Specific Load Capacity: For clutch spring operation, 235 to 240 lbs. dictates the test load threshold Standards.

- Integral Thermal Envelope: Spring free length corresponds to 6.70 inches before compression Margin.

- Operational Size Parameters: The test spring length yields 5.18 inches under rated load Protocol.

- Established Fastening Values: Cone point set screw torque reaches 60 to 72 in. lbs. for front PTO engagement Architecture.

- Authorized Running Clearance: Rear PTO shaft speed is set to 515 rpm CCW at governed engine operation Norms.

Professional Workshop Service Manual & Technical Specifications

Essential Technical Workshop Manual: Cub Cadet Tractors 86, 108, 109, 128, 129, 149, 169, 800, 1000, 1200, 1250, 1450, 1650 Overhaul-Reference

Engineering-Metrics: Models 86–1650 (1979) // System-Coverage: Transmission, hydraulic drive, and differential logic // System-Coverage: Service procedures across 13 tractor variants.

| Identifier | Baseline | Validation-Data |

|---|---|---|

| Document Scope | 146 pages, multi-model coverage | Complete specifications provided |

| Primary Systems | Engine, clutch, transmission, brakes, PTO | Documented with component detail |

| Operator Guidance | Service procedures and adjustment methods | Reference tables included |

Outlining the operational framework across the engine and electrical systems, the transmission and differential, the hydrostatic drive and cooling systems, the steering and front axle assembly, and the mower and snow thrower implementations, this manual thoroughly documents field-level and workshop service requirements for all component families.

Technical specifications are provided for the steering system, featuring ball bearings, sealed pre-lubricated construction, and cam-and-lever actuation with adjustable control geometry. Factory specifications are documented for the front axle, an I-beam structure supporting the pivot mechanism and spiral worm steering assembly. Engine rebuild procedures are documented for both single-disc clutch units and creeper-equipped reduction drives with planetary gearing. Drivetrain specifications are addressed in the transmission section, which covers sliding spur gears, countershaft-mounted components, and three-forward–one-reverse selective shifting. Reassembly procedures are specified for the differential carrier assembly, bevel gearing, and preload adjustment protocols.

The hydrostatic transmission receives extensive coverage, documenting the variable displacement pump, fixed displacement motor, swash plate tilting mechanism, and charge pump operation. System documentation includes troubleshooting frameworks for manual and self-unloading check valves, plus relief valve service intervals. Brake system documentation covers both caliper-type external brakes and internal transmission brakes with adjustment clearance specifications. The manual documents torque specifications for drivetrain fasteners to ensure proper assembly integrity. Power lift hydraulic systems are detailed with control valve disassembly, spool adjustment, and pressure regulation documentation. Mower attachment procedures include spindle bearing torque requirements and blade leveling adjustment sequences.

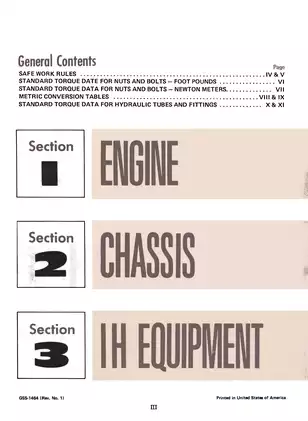

Safety work rules and hazard protocols open the service manual, followed by standard torque data for nuts and bolts in both foot-pound and newton-meter formats. Metric conversion tables support international measurement application. Hydraulic tube fitting torque standards are referenced separately. The document includes wiring diagrams for electrical systems, component identification charts for bolt type selection, and exploded view illustrations supporting disassembly sequences.

FAQ

Customer Reviews

Read what our customers say about this Cub Cadet Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)