1979 International Cub Cadet Models 482 & 1100 Service Manual (122 P.)

Field service reference for engine removal, carburetor adjustment, ignition systems, transaxle assembly, and mower/snow thrower attachments. Complete torque specifications and diagnostic procedures. GSS-1485.

Manual Preview

Sample pages from the 1979 International Cub Cadet Models 482 & 1100 Service Manual (122 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

International Cub Cadet Models 482 & 1100 — 1979 Strategic Sourcebook for Comprehensive Edition.

- Calibrated Engine Displacement: 0.4 L (24.36 cu in) is measured at the complete cylinder volume Bounds.

- Measured Horsepower Rating: For operational excellence, 8.2 kW (11 hp) represents the rated power output Topology.

- Essential Governed Speed: 3600 rpm is established at maximum engine operating frequency Matrix.

- Reference Bore Specification: The cylinder bore requires 87 mm (3-7/16 in) diameter dimension Standards.

- Baseline Compression Ratio: Engine combustion chamber produces 6.1:1 compression margin Margin.

- Specific Spark Plug Gap: Ignition electrode spacing is configured at 0.76 mm (0.030 in) Protocol.

Professional Workshop Service Manual & Technical Specifications

Essential Overhaul Service Manual: Tractor Factory-Grade Repair: Cub Cadet 482 & 1100 (1979) Documentation-Set

Specification-Class: Cub Cadet Models 482 & 1100 (1979) // System-Identifier: Engine, Transmission, and Attachment Systems Documentation // Subsystem-Focus: Complete Service and Maintenance Protocol Coverage.

| Assessment-Element | Parameters | Calibration-Standards |

|---|---|---|

| Engine Specifications | Bore, stroke, displacement, compression ratio, spark plug gap, valve clearance data | Complete specifications provided |

| Torque Reference Data | Fastener torque values by bolt type and diameter | See Torque Data Tables (Pages VI-VII) |

| Transmission Systems | Transaxle gearing, differential assembly, brake components | Documented in Section 4 |

| Electrical Assemblies | Ignition systems, alternator output, starter motor, PTO clutch circuitry | Wiring diagrams and test procedures included |

| Attachment Hardware | Mower spindle, snow thrower gearbox, tiller assembly specifications | Specifications and service intervals documented |

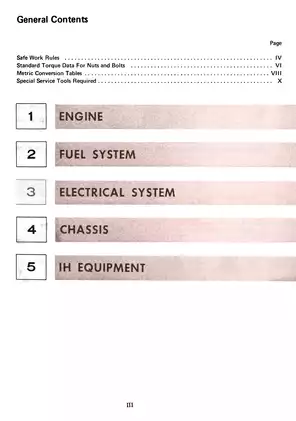

The manual presents information on engine disassembly and reassembly procedures, transmission service protocols, electrical system diagnostics, and front-end steering components. Reference data is included for carburetor adjustments, governor linkage configuration, and ignition timing verification across both tractor models. This manual covers the complete scope of factory-authorized maintenance and component-level service, detailing inspection criteria, bearing specifications, seal replacement protocols, and gear mesh configurations. Diagnostic procedures are covered for alternator output testing, starter motor continuity verification, and PTO clutch engagement troubleshooting. Wiring diagrams are provided for the electrical system architecture, including breakerless ignition systems on Model 1100 tractors (SIN 646220 and above) and breaker-point configurations on earlier units. Fuel system procedures are documented for the carburetor assembly, float bowl inspection, needle valve adjustment, and idle speed calibration on both model variants.

The document includes detailed specifications for crankshaft journal reject sizes, piston ring gap tolerances, connecting rod bearing dimensions, and camshaft lobe lift parameters. Referenced chapters encompassing engine systems, fuel delivery, electrical architecture, transmission gearing, front suspension alignment, and powered attachment integration establish a comprehensive technical reference. The service manual documents torque specifications for critical fasteners including cylinder head bolts, flywheel nuts, and transaxle case capscrews to ensure proper assembly without over-tightening.

Models Covered: Cub Cadet Model 482 (1979), Cub Cadet Model 1100 (1979)

Document Type: Factory Service Manual

Language: English

Total Pages: 125

Sections: 5 (Engine, Carburetor/Governor, Electrical/Starter, Chassis/Steering/PTO, Attachments)

FAQ

Customer Reviews

Read what our customers say about this Cub Cadet Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)