2004-2005 Cub Cadet Domestic 7000 Series Compact Tractor Service Manual (198 P.)

Complete hydraulic system documentation for 7200, 7205, 7260, 7264, 7265, 7300, 7305 compact tractors with Mitsubishi diesel and Kohler gas engine specifications, torque parameters, and component breakdown procedures.

Manual Preview

Sample pages from the 2004-2005 Cub Cadet Domestic 7000 Series Compact Tractor Service Manual (198 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Cub Cadet Domestic Series 7000 ( 769–01634) — 2004–2005 Licensed Strategic Specification | Compact Transmission Repository.

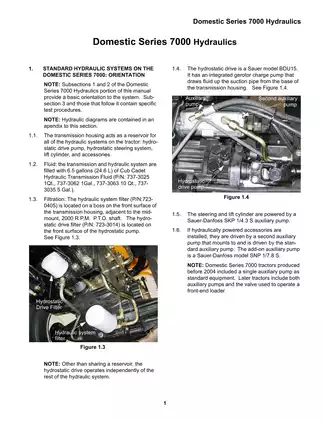

- Measured Holding Capacity: The transmission and hydraulic system are filled with 6.5 gallons (24.6 L) of Cub Cadet Hydraulic Transmission Fluid, establishing the baseline reservoir volume Benchmarks.

- Established Measurement Bounds: Charge pump pressure is maintained between 70 and 150 PSI (4.8 to 10.3 Bars) at 1,200 RPM, defines the pressurization limits Range.

- Factory Circuit Specs: The SKP1/4.3 S auxiliary pump produces roughly 3,600 PSI (250 bars) at engine speeds beyond 1,200 RPM, achieves maximum output potential Sequences.

- Integral RPM Specs: The auxiliary pump was observed to move about 4.6 Gal./min. (15 L/min.) at an engine speed of 3,000 RPM, determines system flow performance Baseline.

- Operational Installation Footprint: The category 1 three point hitch system should be capable of lifting 950 lbs. (430 Kg.), 24 in. (61 cm.) behind the hitch, sets the maximum load capacity Requirements.

- Critical Charge Quantity: Relief valve setting reaches 9,860–10,825 kPa (1,430–1,570 psi) for drop axle assembly protection, maintains system safety boundaries Threshold.

Professional Workshop Service Manual & Technical Specifications

Definitive Technical Documentation: Cub Cadet 7200 7205 7260 7264 7265 7300 7305 Tractor Service Manual Overhaul-Reference

Operational-Scope: Domestic Series 7000 compact tractors (Diesel/Gas variants) // System-Coverage: Hydraulic systems, transmission mechanics, electrical circuits, and drivetrain architecture // Service-Level: Complete technical specifications for authorized service technicians and experienced equipment specialists.

The document encompasses factory service procedures across five primary technical domains. Cooling system maintenance is addressed in dedicated sections covering radiator service, thermostat operation, and overflow system management. Power steering systems receive detailed treatment, including Sauer and Ross pump identification, cylinder operation, and pressure testing methodology. The troubleshooting chapter addresses common operational issues within hydraulic steering, discussing relief valve function, spool movement, and leaf spring performance. Electrical system logic is mapped across instrument panel circuits, switch configurations, and battery management protocols. Transmission disassembly procedures document motor shaft assembly extraction, PTO actuator removal, and differential lock mechanism service.

Technical notes are provided for multiple pump architectures (Sauer-Danfoss SKP and SNP models), variable displacement hydrostatic drive systems, and tandem auxiliary pump configurations. Quality checks are addressed for charging systems on Caterpillar, Briggs & Stratton, Kohler, and Kawasaki engine platforms. The manual documents torque specifications for MFD mounting brackets, steering cylinder hardware, and axle bearing assemblies to ensure proper assembly tension.

| Documentation Section | Technical Focus | Specifications Included |

|---|---|---|

| Hydraulic Systems | Charge pump operation, flow testing, relief valve adjustment | Pressure ranges 70-150 PSI (charge); 1,500 PSI (system relief) |

| Front Axle Assembly | Differential backlash, bearing preload, gear tooth contact | Pinion drag 22.5-31.5 lbs; backlash .004"-.006" |

| Transmission Housing | Component breakdown, seal specifications, oil capacity | 6-gallon hydraulic fluid capacity documented |

| Steering Components | Pump models, cylinder sizing, pressure relief settings | Sauer: 1,087-1,160 PSI; Ross: 1,450 PSI reference data |

| PTO Systems | Clutch assembly inspection, shaft alignment, detent positioning | Multiple RPM configurations with selection methodology |

Accurately demanding attention to component orientation and fastener application, the manual details engine removal and installation procedures including driveshaft separation, compression mount positioning, and flywheel marking protocols. The document includes wire routing diagrams for main harness integration, connector identification by color and gauge, and circuit logic documentation. Fuel system assembly is covered through filter replacement, line routing, and return-path verification. Brake system service encompasses wear measurement, link adjustment, and ferrule positioning. Three-point hitch removal and reinstallation procedures address upper arm extraction, feedback rod disconnection, and load test preparation. Four-wheel drive front axle service includes final drive assembly separation, pinion gear extraction, and differential setup using prussian blue pattern verification. Neutral control adjustment is documented with linkage routing detail and scissors bracket centering methodology.

The document provides references to included specifications for component assembly, detailing how hydrostatic transmission control requires proper neutral detent positioning, how PTO control lever travel must align with transmission engagement windows, and how brake pedal linkage adjustment affects stopping performance. Sections addressing universal joint clearance reference specifications for input shaft seal protection and spacer tool application. MFD bracket torque documentation is cross-referenced with locking feature status and thread compound application guidance.

| Component Category | Assembly Reference | Documentation Detail |

|---|---|---|

| Hydraulic Connections | Port identification and pressure ratings | Sauer vs. Ross pump port naming conventions included |

| Engine Gaskets | Material specifications and sealant requirements | Loctite product numbers and application thickness documented |

| Seal Installation | Driver tool requirements and chamfer orientation | Multiple seal types with specific installation depth references |

| Bearing Preload | Drag measurement methodology and torque application | Spring collapse techniques and final locking procedures detailed |

Throughout the transmission disassembly section, the manual documents component positioning within the housing, bearing retention methods, and gear mesh alignment procedures. PTO shield removal and installation sequences ensure proper cooling flow. Rear housing cover separation utilizes factory school-provided hex cap screws as prying leverage points, with subsequent reassembly requiring sealant application and bolt torque specification compliance. Two-speed collar orientation within the PTO back shaft assembly must maintain the thin groove facing toward the transmission rear. Hydraulic oil filter access and replacement procedures are detailed with capacity notation.

FAQ

Customer Reviews

Read what our customers say about this Cub Cadet Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)