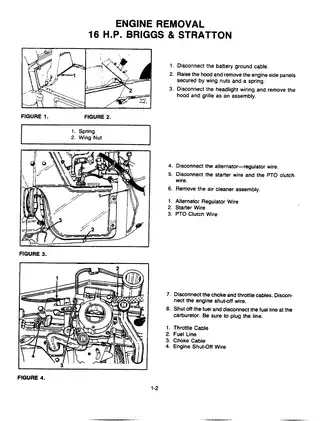

Briggs & Stratton 16 HP / Kohler 17 HP Twin / Onan 20 HP Service Manual

Covers engine removal and installation procedures for Briggs & Stratton 16 HP, Kohler 17 HP twin cylinder, and Onan 20 HP diesel engines with step-by-step technical guidance and component specifications.

Manual Preview

Sample pages from the Briggs & Stratton 16 HP / Kohler 17 HP Twin / Onan 20 HP Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Briggs & Stratton 16 HP, Kohler 17 HP Twin, Onan 20 HP — Diesel Engine Series Certified Reference Archive | Diesel Engine Segment.

- Designated Thermal Envelope: The engine cooling system is standardized to maintain 180–200°F (82–93°C) operational temperature Mapping.

- Verified RPM Specs: For optimal performance, 3600 rpm defines the rated engine speed Configuration.

- Nominal Physical Specs: The 16 HP Briggs & Stratton achieves 42 kg (92.5 lb) dry weight Benchmarks.

- Design Coupling Torques: Maximum crankshaft output reaches 43 N·m (32 lb-ft) at rated speed Range.

- Engineered System Fill: Oil capacity determines 1.9 L (2 qt) for proper lubrication Sequences.

- Essential Cooling Specs: Radiator coolant volume reaches 3.8 L (1 US gal) system baseline Baseline.

Professional Workshop Service Manual & Technical Specifications

Complete Wiring Manual: Diesel Engine Official Briggs & Stratton 16 HP, Kohler 17 HP Twin & Onan 20 HP Diesel Engine Removal & Installation Procedures Chassis-Documentation

System-Coverage: 16 H.P. Briggs & Stratton, 17 H.P. Twin Cylinder Kohler, 20 H.P. Onan // Coverage-Scope: Diesel engine removal and installation procedures / Multi-manufacturer technical logic // Series-Validation: 190-page comprehensive diesel engine documentation.

| Document Section | Content Focus | Reference Status |

|---|---|---|

| Engine Systems Overview | Diesel powerplant configuration and component layout | Documented across manual sections |

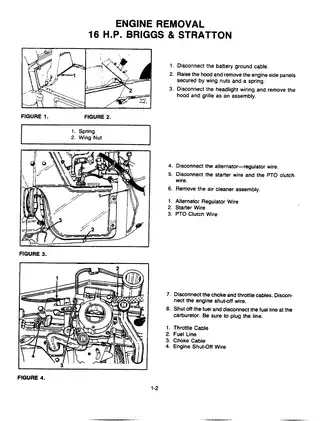

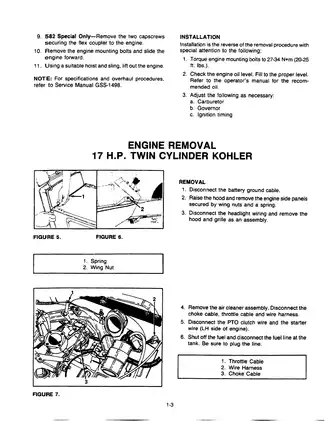

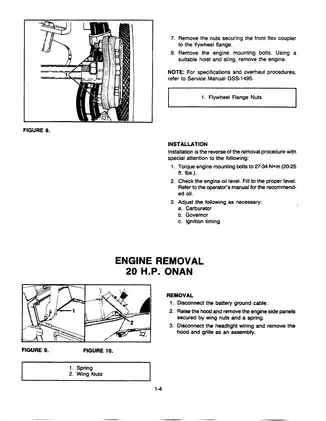

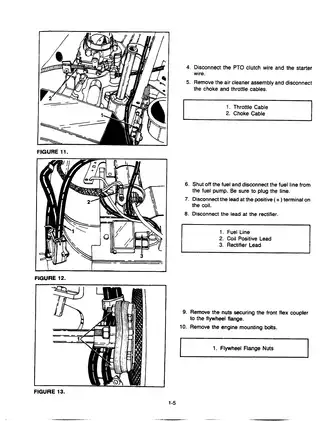

| Removal Procedures | Step-by-step methodology for engine extraction | Complete specifications provided |

| Installation Protocols | Reassembly sequence and alignment procedures | See detailed chapters |

Coverage is segmented into engine removal procedures, installation methodologies, component assembly sequences, operational verification protocols, and technical reference data. This manual combines removal and installation guidance across three distinct diesel engine platforms, addressing the Briggs & Stratton 16 horsepower single-cylinder design, the Kohler 17 horsepower twin-cylinder configuration, and the Onan 20 horsepower unit.

Timing procedures are documented for engine synchronization and operational readiness. Technical notes are provided for component compatibility and fastener requirements. Quality checks are addressed for post-installation verification. The electrical system section documents wiring architecture and circuit integration pathways. The troubleshooting chapter addresses common operational concerns and diagnostic procedures.

Accurately requiring precise attention to specification details, the manual documents torque specifications for critical fasteners to ensure proper fastener fatigue prevention. This practical pathway through engine removal and installation procedures provides the necessary technical framework for multi-brand diesel engine service work across industrial and agricultural equipment applications.

FAQ

Customer Reviews

Read what our customers say about this Briggs Diesel Engine manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)