EPSON Stylus CX6300 / CX6400 / CX6500 / CX6600 Service Manual

Comprehensive service manual for EPSON Stylus CX6300/CX6400/CX6500/CX6600 printers. Covers all aspects of maintenance, disassembly, and troubleshooting. Part numbers like C545 MAIN and T0441 included.

Manual Preview

Sample pages from the EPSON Stylus CX6300 / CX6400 / CX6500 / CX6600 Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

EPSON Stylus CX6300/CX6400/CX6500/CX6600 (C545 MAIN) — 2003–2004 Printer / Scanner / Copier Service Manual Archive | CX Series Dossier.

- Maximum Fluid Levels: 1440 × 720 dpi corresponds to the maximum print resolution capability Parameters.

- Universal Adjustment Range: For optimal scanning performance, 1200 × 2400 dpi is calibrated to the optical capture standard Topology.

- Fundamental Energy Draw: 180 monochrome nozzles — determines the printhead ejection architecture Specifications.

- Specific Burn-in Temperature: The operating envelope requires 10–35°C for standard thermal conditions Protocol.

- Published Enclosure Specs: Device weight reaches 9.0 kg and sets the physical configuration boundaries Framework.

- System Storage Capacity: Total displacement dictates 450 × 429 × 218 mm (W × D × H) dimensional constraint Topology.

Professional Workshop Service Manual & Technical Specifications

EPSON Stylus CX6300 / CX6400 / CX6500 / CX6600 Service Manual (125 P.) Service-Portfolio

Documentation-Type: Service Manual // Application-Range: CX6300, CX6400, CX6500, CX6600 // Technical-Scope: Printer, Scanner, Copier

Fundamentally requiring detailed operational guidance, this manual documents the comprehensive framework for the EPSON Stylus CX6300/CX6400/CX6500/CX6600 printer.

| Assessment-Element | Operational-Logic | Framework |

|---|---|---|

| Manual Configuration | System Layout | Schematics |

| Troubleshooting Guide | Error Diagnosis | Resolution Flowcharts |

| Disassembly Procedure | Unit Removal | Component Access |

| Printer Mechanism | Operation Principles | Drive Systems |

| Scanner Mechanism | Image Capture | Optical Path |

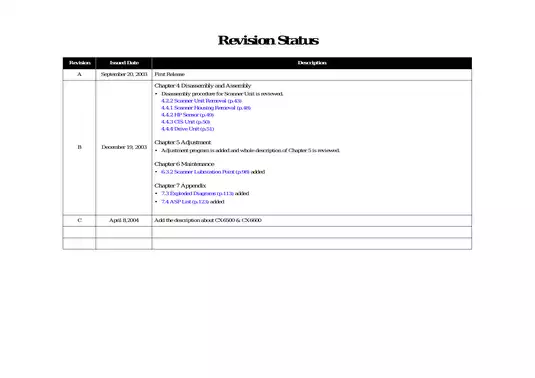

Outlining the operational framework across all key systems, this manual provides an in-depth look at the printer's internal workings. It details procedures for disassembly and assembly, covering major unit removals like the panel unit, scanner unit, and printer unit. Specialized sections are dedicated to specific components such as the printhead, linear scale, CR motor, and the paper feeding mechanisms.

Furthermore, the manual includes extensive troubleshooting sections addressing common issues like paper jams, ink errors, and scanner malfunctions. It also covers essential maintenance tasks, including cleaning and lubrication, with specific guidance on grease types and application points. Adjustment procedures, both mechanical and software-based, are clearly outlined, ensuring optimal printer performance after component replacement.

This document includes extensive diagrammatic representations and part lists for accurate identification and servicing of all components.

FAQ

Customer Reviews

Read what our customers say about this Epson Printer manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)