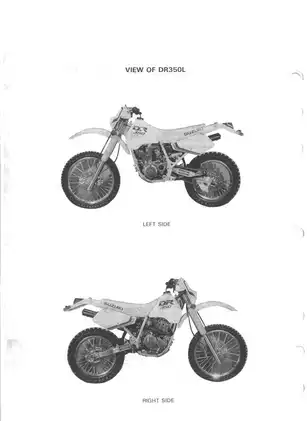

1990-1999 Suzuki DR350 / DR350S / DR350SE Service Repair Manual (797 P.)

Complete service manual with engine specs, carburetor MIKUNI TM33SS/BST33SS, transmission 6-speed, fuel tank 9.5L, four-stroke OHC single-cylinder engine. Full procedures for maintenance and overhaul with torque specifications and special tools.

Manual Preview

Sample pages from the 1990-1999 Suzuki DR350 / DR350S / DR350SE Service Repair Manual (797 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Suzuki DR350, DR350S & DR350SE — 1990–1999 Technical Archive Compilation | DR350 Series Repository.

- Nominal Displacement Data: 349 cm³ (21.3 cu in) is specified as the engine cylinder volume Specifications.

- Principal Power Output: For optimal performance, the engine achieves 20.9 kW (28 hp) maximum rated horsepower Baseline.

- Rated Torque Specification: The crankshaft develops 35–40 N·m (25.5–29.0 lb-ft) at the cylinder head fastening requirement Threshold.

- Calibrated Valve Clearance: Intake valve gap is measured at 0.05–0.10 mm (0.002–0.004 in) cold lash setting Requirements.

- Documented Fuel Capacity: Tank volume reaches 9.5 L (2.5 US gal) including 1.8 L (0.5 US gal) reserve Mapping.

- Design Oil Capacity: Engine oil holds 1700 ml (1.8 US qt) during standard oil change configuration Configuration.

Professional Workshop Service Manual & Technical Specifications

Professional Installation Manual: Suzuki DR350, DR350S & DR350SE Service & Repair Manual 1990-1999 Repository

Technical-Domain: DR350L, DR350S, DR350M, DR350SM, DR350N, DR350SN, DR350P, DR350SP, DR350R, DR350SER, DR350S, DR350SES, DR350T, DR350SET, DR350V, DR350SEV, DR350W, DR350SEW, DR350X, DR350SEX (1990-1999) // Technical-Benchmarks: Four-stroke single-cylinder / Dry sump lubrication Logic // System-Coverage: Engine assembly, transmission, electrical subsystems, comprehensive chassis procedures.

| Topic Category | Reference Source | Documentation |

|---|---|---|

| Periodic Service Schedule | Chapter 2 | Maintenance intervals and component service procedures provided |

| Engine Systems | Chapters 3-4 | Complete engine disassembly, reassembly, and component specifications documented |

| Electrical Function | Chapter 5 | Ignition system, magneto coil resistance, CDI unit testing parameters included |

Systematizing the service groups into engine maintenance, fuel and lubrication circuits calls for transmission service information covers both standard and emission-controlled procedures, while chassis procedures document suspension adjustment and brake system configuration, and electrical system coverage furnishes ignition timing and lighting circuit information, then supplement these with comprehensive specifications and torque application references.

Service procedures are grouped by OEM guidelines are included for cylinder head fastener assembly and piston ring placement. Transmission service information covers six-speed constant mesh gear arrangements and drive chain slack settings. Cooling system procedures are included for engine lubrication monitoring through oil level inspection and filter replacement cycles. Torque specifications are documented for engine mounting hardware to ensure proper bolt stretch prevention. Parts identification is covered for carburetor jet configurations and valve clearance measurement points.

The manual documents comprehensive service procedures across major subsystems. Engine chapters address cylinder head servicing, valve adjustment protocols, and piston ring positioning requirements. Fuel system data includes carburetor construction details and float height adjustment specifications. Brake system procedures cover disc pad replacement sequences and master cylinder servicing steps. Suspension chapters encompass front fork oil level adjustment and rear shock absorber spring preload modification techniques. Electrical section contains magneto coil resistance testing procedures and spark plug gap verification protocols. The document includes wiring diagrams illustrating lead wire routing, cable guide placement, and hose clamp positioning throughout the chassis framework.

| Maintenance Topic | Interval Specification | Service Description |

|---|---|---|

| Oil and Filter Service | Every 60 hours (initial 5 hours) | Oil change and filter replacement with specific API classification requirements |

| Valve Clearance Inspection | Every 60 hours (initial 5 hours) | Intake and exhaust valve adjustment procedures with cold engine specifications |

| Spark Plug Service | Every 30-60 hours | Inspection, carbon cleaning, and replacement guidelines with heat range selection |

| Brake Fluid Level | Initial 5 hours, every 30 hours | Reservoir inspection and DOT 4 fluid replenishment documentation |

| Drive Chain Maintenance | Every 1,000 km (each ride) | Tension adjustment, slack measurement, and lubrication with specified oil types |

Separate table identifies document overview organization including dedicated chapters for general information with VIN identification procedures, periodic maintenance schedules with hour-based intervals, and engine component removal sequences. Intake and exhaust valve service sections document both standard and emission-controlled specifications for DR350S variants. Transmission troubleshooting guides include gear shift fork clearance measurements and final reduction ratio calculations. Carburetor sections reference MIKUNI TM33SS and BST33SS specifications with jet numbering systems for mixture control. Electrical chapters cover PEI ignition timing control and battery charging system operation principles. Chassis information addresses both telescopic front fork assemblies and link-type rear suspension configurations with damping force adjustment procedures.

The document includes detailed component specifications across all major systems. Engine displacement, bore and stroke measurements, and compression ratios are tabulated for reference. Transmission gear ratios from low through top gear appear in specification tables. Electrical wiring diagrams illustrate color-coded lead wire connections and switch terminal configurations. Brake system disc thickness and runout service limits are documented. Tire pressure tables reference both solo and dual riding load conditions. Fork oil viscosity ratings and suspension spring preload adjustment positions are specified. The manual documents torque specifications for engine mounting bolts to ensure proper fastener tightening sequences.

DR350S model variants receive dedicated attention with separate specifications for fuel tank capacity, carburetor I.D. numbers, and tire sizes. Emission control carburetor components are featured with close-tolerance jet identification systems. Battery specifications including capacity ratings and electrolyte S.G. values are detailed. Charging system operation and regulator function principles are explained. Troubleshooting charts address generator charging performance, battery discharge conditions, and alternator output specifications. Cable and hose routing sections illustrate proper clamp positioning throughout the frame assembly.

The document provides service data tables covering valve specifications, camshaft journal clearances, piston ring groove measurements, and crankshaft runout limits. Oil pump reduction ratios and clutch spring free lengths are tabulated. Drive chain link counts and 20-pitch length specifications are documented. Carburetor float height adjustment values are included. Suspension spring preload settings and shock absorber gas pressure ratings appear in specification sections. Electrical component resistance values and voltage output requirements are provided. Brake disc thickness limits and wheel bearing runout specifications complete the reference material.

The manual documents comprehensive wiring diagrams for standard models and DR350S variants, illustrating ignition coil connections, magneto lead wire routing, and lighting circuit configurations. Cable routing sections specify clutch cable guide placement, de-compression cable path management, and throttle cable feed through frame openings. Hose routing diagrams show brake fluid line clamp positions, crankcase breather hose alignment, and fuel vapor separation procedures for emission-controlled models. Electrical schematic components include neutral indicator switches, side stand interlock switches, and brake light activation points. The document provides complete troubleshooting procedures addressing engine starting issues, electrical charging system performance, carburetor mixture control problems, and brake system hydraulic operation.

FAQ

Customer Reviews

Read what our customers say about this Suzuki Motorcycle manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)