1975-1976 Triumph Trident T160 Workshop Manual (198 P.)

Complete T160/T150 750cc three-cylinder service and repair procedures, electrical diagrams, torque specifications with disc brake, transmission, and fuel system detail. OEM-sourced technical documentation covering disassembly, maintenance, and rebuilding sequences.

Manual Preview

Sample pages from the 1975-1976 Triumph Trident T160 Workshop Manual (198 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Triumph Trident T160 (99-0973) — 1975–1976 Established Reference Manual | Trident Series Unit.

- Calibrated Displacement Data: 740.4 cm³ (45.2 cu. in.) is measured at the engine cylinder volume Architecture.

- Measured Power Output: For optimal performance, 28 hp at 6500 rpm is set to the maximum rated horsepower Norms.

- Primary Torque Specification: 145 N·m (107 lb-ft) at 5000 rpm — limits the peak crankshaft output capability Bounds.

- Advanced Compression Ratio: The cylinder head requires 9.5:1 for standard combustion chamber pressure Topology.

- Operational Fuel Capacity: Tank volume maintains 20 L (5 U.S. gal) Parameters.

- Specific Valve Clearance: Intake/exhaust gap is established at 0.006–0.008 in. (0.15–0.20 mm) cold adjustment Standards.

Professional Workshop Service Manual & Technical Specifications

Triumph Trident T160 1975-1976 Workshop Manual (99-0973)

Strategic Performance Manual: Triumph Trident Complete Workshop Manual for Triumph Trident T160/T150 Motorcycle (# 99–0973) | OEM Specs Field-Reference

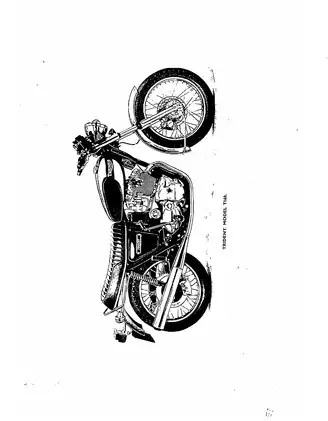

Technical-Benchmarks: Triumph T160 Trident 750cc, T150 Early Models // Specification-Class: Engine and Transmission Systems / Complete Specifications // Conceptual-Layout: 198-page comprehensive factory documentation with technical diagrams.

| Metric | Technical-Path | Calibration-Data |

|---|---|---|

| Three-Cylinder Engine | Displacement: 750cc (45 cu. in.), 9.5:1 compression | Documented specifications provided |

| Crankshaft Configuration | 120-degree three-throw design with roller/ball main bearings | Complete bearing dimensional data |

| Valve Timing Systems | Inlet/exhaust camshaft pinions with auto advance mechanism | See Chapter B pages |

| Primary Drive | Duplex chain transmission via shock absorber to diaphragm clutch | Sprocket alignment procedures documented |

| Transmission System | Five-speed constant mesh with gearbox sprocket drive | Full gear ratio calculations included |

Major sections focus on the engine and cylinder head assembly, which involves detailed inspection and maintenance of all combustion chamber components, and the transmission and gearbox mechanisms, which encompasses gear selection camplate operation and bearing specifications, along with the electrical system incorporating contact breaker ignition and alternator charging architecture, the frame and suspension systems including swinging fork adjustment and rear damper units, and the front telescopic fork assembly with hydraulic damping and steering head adjustment procedures. The primary drive systems document primary chain tensioning and clutch operating mechanism calibration, the braking systems reference hydraulic disc brake bleeding sequences and caliper piston maintenance, and the wheels and tire systems provide bearing lubrication schedules and chain adjustment protocols.

Technical content addresses the rotary oil pump with internal feed and scavenge gears operating at 1.9:1 drive ratio from the crankshaft, documenting torque specifications for the cylinder head to ensure proper cyclic stress resistance. The manual provides comprehensive detail on contact breaker lubrication at the camshaft-mounted seven-point-A unit, with auto-advance centrifugal mechanisms operating at 2,000 r.p.m. full advance conditions. Fuel system information includes specifications for triple Amal model 626 concentric carburetors with common linkage control and pilot air screw adjustment procedures.

Accurate assembly procedures for the three-cylinder engine block are included with protective connecting rod installation protocols, piston ring gap measurement techniques, and cylinder bore honing specifications for new ring bedding. The document provides reference data for main bearing journal dimensions, cam follower inspection criteria using steilite-tip identification methodology, and tappet guide block clearance tolerance references. Cooling system lubrication networks are documented through the oil cooler mounting bracket configurations and rocker oil feed pipe connection procedures.

Troubleshooting guidance addresses ignition system operation through static spark timing at 38 degrees before T.D.C. using service tool location methods, ignition coil continuity verification across the contact breaker point sets, and stroboscopic timing mark alignment techniques for running engine adjustments. Brake system procedures reference bleeding operations for both front and rear hydraulic circuits, master cylinder reservoir fluid level maintenance, and caliper piston seal replacement using Lockheed disc brake lubricant specifications. Electrical charging system documentation includes alternator A.C. output verification at 3,000 r.p.m., silicon diode bridge rectifier testing sequences, and Zener diode voltage regulation procedures for 12-volt battery protection.

OEM Technical Details

This original equipment manual incorporates genuine factory engineering data compiled after the Meriden factory closure, preserving technical specifications and assembly procedures that became unavailable following production discontinuation. The document references original workshop practices including service tool part numbers, torque wrench settings for engine and transmission assemblies, and component clearance tolerances from the original design documentation. Wiring diagrams and electrical schematic details provide complete system architecture for the three-coil ignition system, starter motor circuit operation, and warning lamp indicator functions.

Service information covers routine maintenance intervals starting at 250 miles for oil tank level verification, progressing through 1,000-mile transmission oil changes, and 12,000-mile brake system fluid renewal procedures. Lubrication specifications are provided for each system component including engine oil (20/50 SAE grade), transmission gear oil (SAE 90 EP), and automatic transmission fluid for telescopic fork damping media. The manual identifies all proprietary component suppliers including Lucas electrical equipment, Girling brake systems, and Amal carburetor manufacturers with their original supplier addresses.

Reference charts at the conclusion include metric-to-imperial conversion tables, torque value references, and complete vehicle dimensional specifications. Exploded assembly diagrams accompany each major system section, with component identification numbering and cross-reference callouts to the general data section. The document was originally compiled by John R. Nelson with contributions from former BSA Service Department personnel, ensuring authenticity of factory specifications and assembly procedures.

FAQ

Customer Reviews

Read what our customers say about this Triumph Motorcycle manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)