1996-1997 Land Rover Defender 300TDI Workshop Manual (458 P.)

Complete workshop procedures for Defender 300TDI covering engine tuning, fuel systems, and suspension specifications. Detailed repair guidance for R380 gearbox, differentials, and brake assemblies. PN LRL 0097 ENG

Manual Preview

Sample pages from the 1996-1997 Land Rover Defender 300TDI Workshop Manual (458 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Land Rover Defender 300Tdi (LRL 0097 ENG) — 1996–1997 Integrated Documentary Manual | Defender 300Tdi Series Division.

- Published Output Rating: 106 hp at 6200 rpm corresponds to the maximum rated engine horsepower Matrix.

- Specific Cooling Specs: For optimal thermal operation, 11.50 litre (20.20 pints) achieves the complete system capacity Specifications.

- Approved Print Rate: 88° C is calibrated to the thermostat opening temperature Standards.

- Reference Precision Specs: The cylinder head requires 19.5:1 ± 0.5:1 is calibrated to the compression ratio Protocol.

- Established Locking Torques: Cylinder head retaining bolts achieve 40 Nm (30 lbf/ft) initial torque in sequence Architecture.

- Authorized Load Capacity: The fuel tank usable fuel is standardized to 89.0 litres (19.5 gallons) Norms.

Professional Workshop Service Manual & Technical Specifications

Thorough Operations Training Manual: SUV Land Rover Defender 300TDI Manual (1996-1997) - Expert Workshop Procedures & Diagnostics Engineering-Archive

System-Identifier: 1996–1997 Defender 300TDI models // Architecture-Focus: Diesel turbocharger and transmission logic // System-Identifier: 458-page comprehensive technical resource.

| Specification | Baseline | Logic |

|---|---|---|

| Engine Type | 2.5L Direct Injection Turbodiesel | Complete operation and overhaul procedures documented |

| Transmission System | R380 Five-Speed Manual + LT230 Transfer Box | All adjustment and repair sequences included |

| Brake Architecture | Hydraulic front disc, rear disc parking | Torque specifications and maintenance steps provided |

| Fuel Delivery | Bosch rotary injection pump with EGR option | Priming, timing, and pressure check data included |

| Suspension Design | Coil spring with telescopic dampers | Component identification and service intervals referenced |

Integrated service sections encompass engine tuning data and general fitting reminders, proceeds with detailed coverage of the 300TDI diesel propulsion unit and fuel system architecture, transitions through cooling system operations and manifold exhaust assemblies, and incorporates clutch transmission mechanisms alongside transfer gearbox functionality and propeller shaft assemblies. The document addresses rear and front axle final drive systems, documents steering power assistance procedures, and concludes with front suspension, rear suspension, brake system, wheels and tires, plus chassis and body supplementary systems.

Effectively requiring technician reference, the manual systematically presents systematic coverage of the 300TDI engine with injection timing marks, crankshaft pulley removal sequences, camshaft drive belt service intervals, and front cover plate gasket specifications. Brake system specifications are included for hydraulic pressure testing methodologies and servo cylinder operation parameters. Safety procedures are documented for fuel system handling precautions, including fuel tank drainage protocols and sedimentor cleaning processes. Fluid capacities are listed for engine sump, cooling system, transmission boxes, axle differentials, and power steering reservoirs. Tool requirements are listed for special service equipment including transmission hoists, axle spreaders, and seal replacement instruments.

The document includes torque specifications for engine block bearing caps, cylinder head fasteners, flywheel housings, crankshaft components, transmission bell housing connections, transfer gearbox mounting brackets, propeller shaft flanges, axle hub assemblies, and suspension linkage attachments. Detailed wiring diagrams accompany the electrical section covering starter motors, generator specifications, battery connections, and instrument illumination circuits. Comprehensive maintenance schedules address engine oil and filter renewal procedures, gearbox and transfer box oil service intervals, front and rear axle lubrication, swivel pin housing grease applications, and brake fluid bleeding protocols.

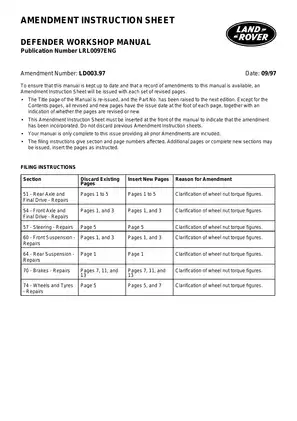

The manual documents torque specifications for the 300TDI engine components to ensure proper joint separation prevention.

FAQ

Customer Reviews

Read what our customers say about this Land Rover SUV manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)