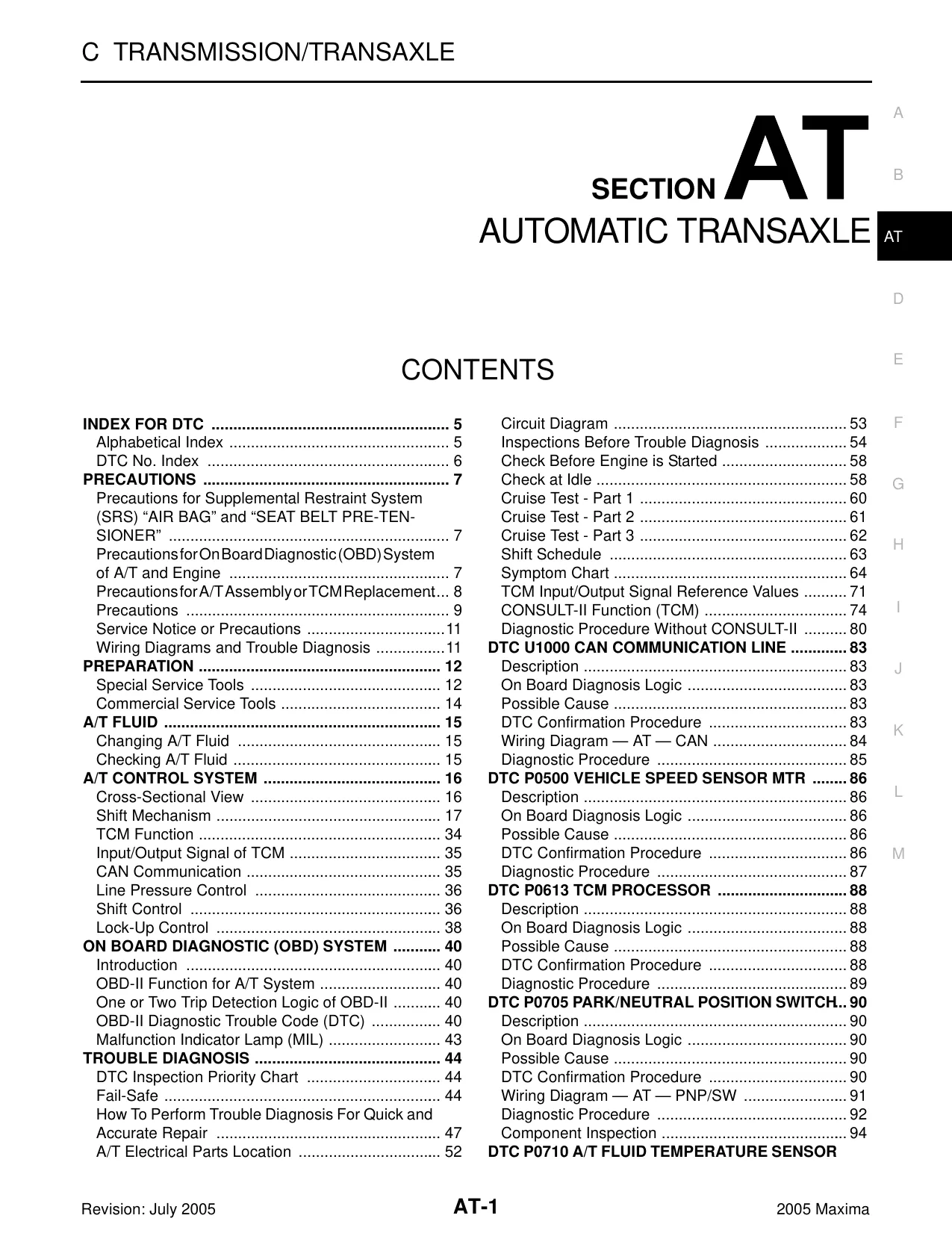

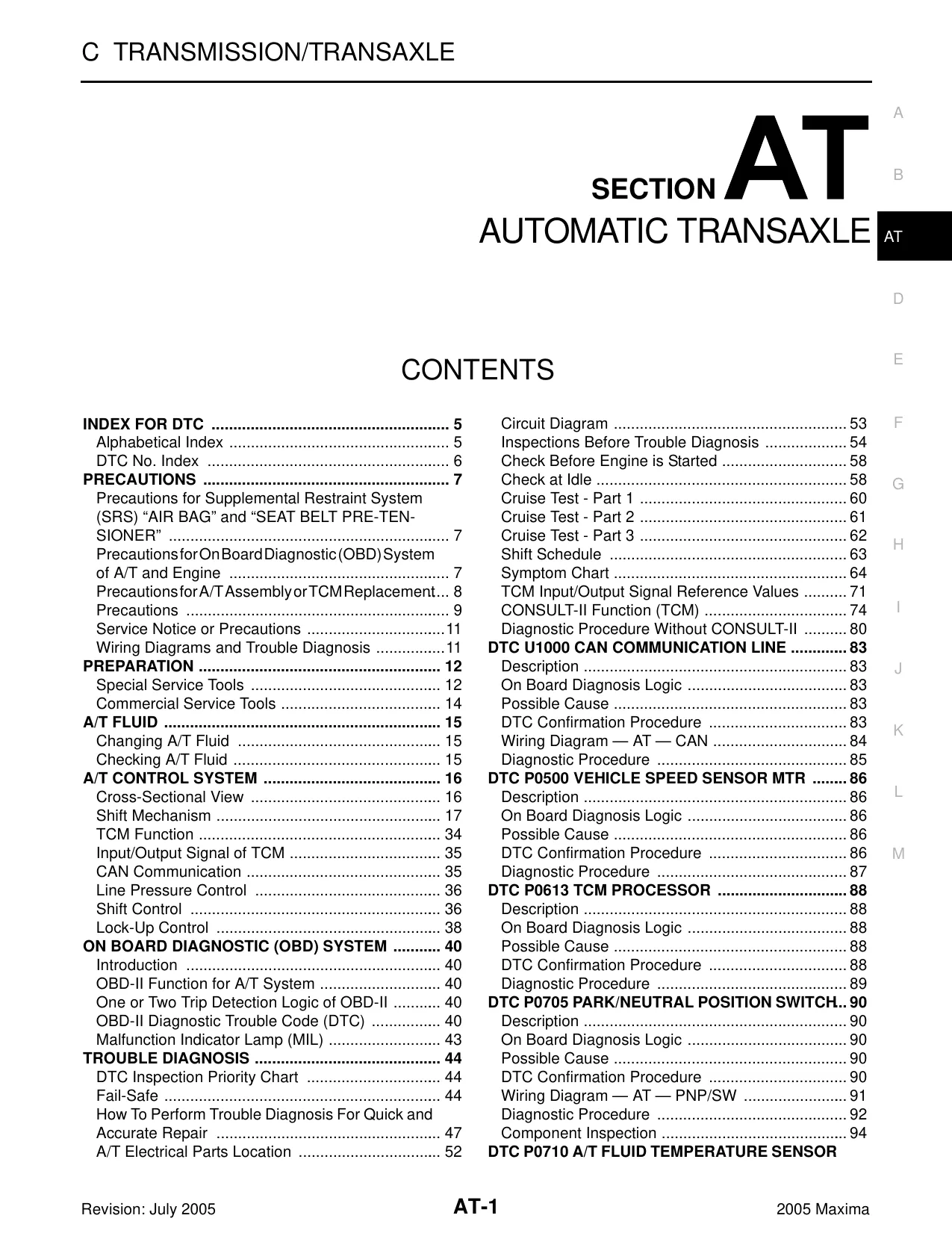

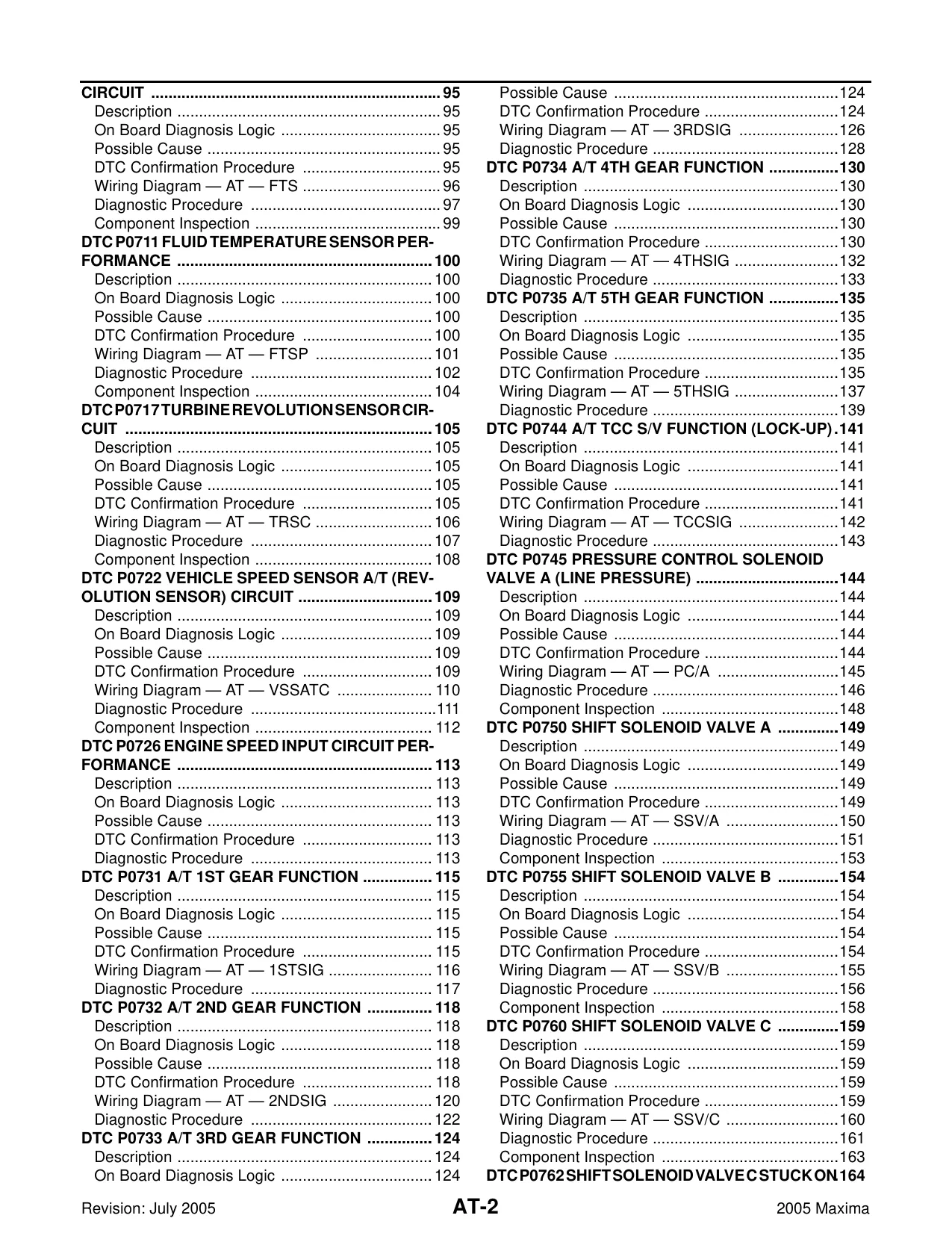

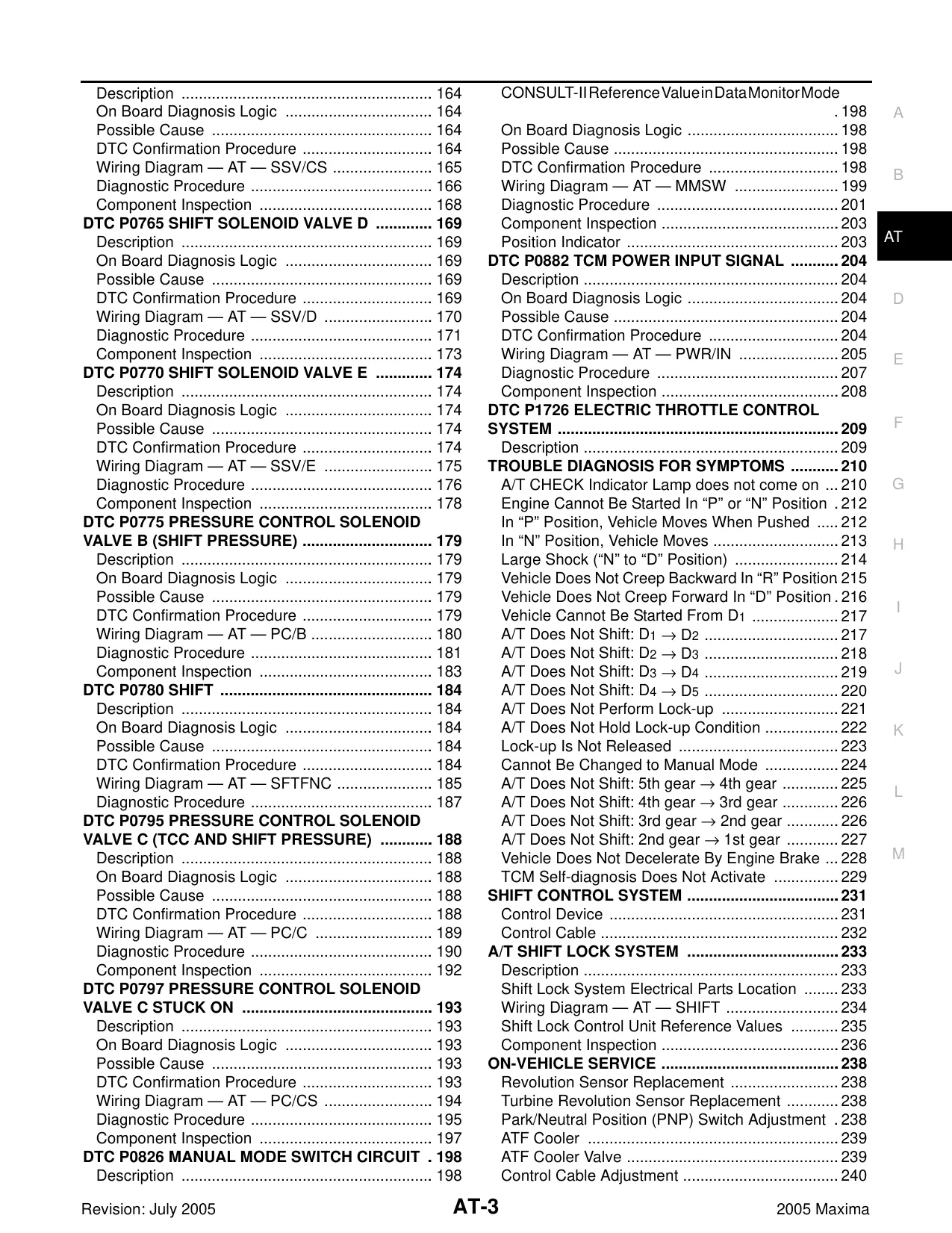

Nissan Maxima manual, covers 2004-2009, Automatic Transaxle

Manual Preview

Sample pages from the Nissan Maxima manual, covers 2004-2009, Automatic Transaxle manual

Purchase & Download

Models Covered & Key Technical Specifications

- Nissan Maxima SE (2004)

- Nissan Maxima SL (2004)

- Nissan Maxima 3.5 SE (2005)

- Nissan Maxima 3.5 SL (2005)

- Nissan Maxima SE (2006)

- Nissan Maxima SL (2006)

- Nissan Maxima SE (2007)

- Nissan Maxima SL (2007)

- Nissan Maxima SE (2008)

- Nissan Maxima SL (2008)

- Nissan Maxima SE (2009)

- Nissan Maxima SL (2009)

Professional Workshop Service Manual & Technical Specifications

Complete Automatic Transaxle Reference for Nissan Maxima

If you’re looking for a single, authoritative workshop document that brings together detailed automatic transaxle system documentation, diagnostic contexts, and structured transmission-level references for Maxima models from 2004 through 2009, this manual delivers exactly that in one comprehensive source.

This document is organized to reflect the factory’s own approach to automatic transaxle systems. Instead of just listing chapter titles, the narrative below translates the table of contents into grouped system descriptions that show how the transaxle, control logic, diagnostic codes, and system specifications are documented.

Precautions and System Awareness

The manual opens with carefully documented precautions covering supplemental restraint systems (SRS), onboard diagnostic systems (OBD), and specific transmission control module (TCM) concerns. This section lays the groundwork for safe and accurate reference to high-pressure components and electronic control logic.

Preparation and Tools Context

A dedicated preparation segment outlines special and commercial service tools that are integral to proper diagnosis and system references. Knowing which tools and data points are required ensures that technicians and experienced DIY owners can connect diagnostic logic with real-world test conditions.

Automatic Transmission Fluid (A/T Fluid) Systems

Transaxle maintenance and fluid system groupings give clear visibility into fluid change and inspection logic. This provides insight into how fluid condition and levels are referenced in the context of system operation rather than only serving as a checklist.

A/T Control System Architecture

A major portion of the manual focuses on the transaxle control system, including cross-sectional views, shift mechanisms, line pressure control logic, lock-up clutch references, and related control signal groupings. This part of the document shows how the transaxle’s electronic control logic is integrated with mechanical components.

On-Board Diagnostic (OBD) Logic for Automatic Transaxle

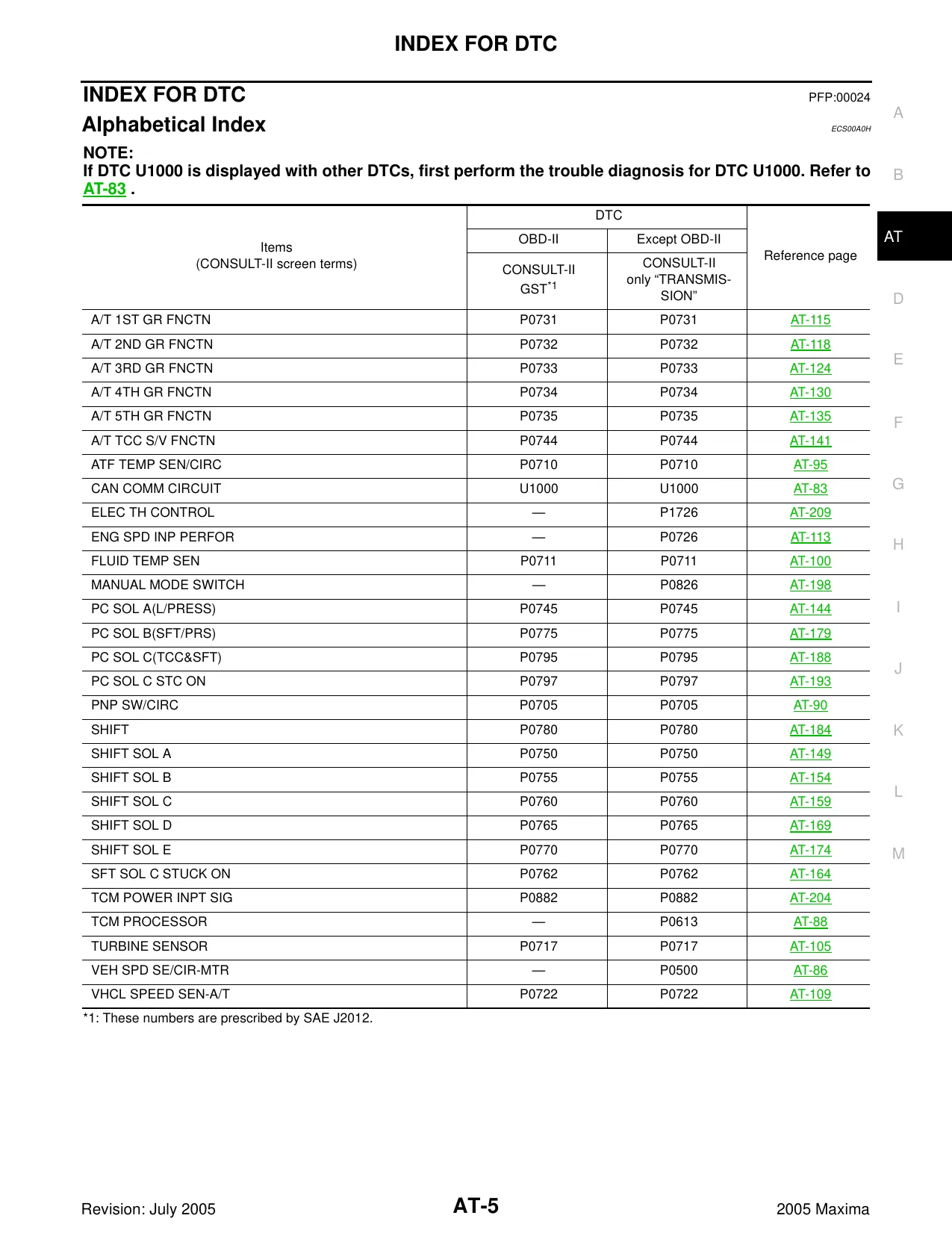

Diagnostic sections organize OBD system logic, detection criteria, the on-board diagnostic trouble code (DTC) framework, and malfunction indicator lamp behavior. These groupings give context on how the Maxima’s automatic system communicates faults and identifies system irregularities.

Trouble Diagnosis and DTC Scopes

The manual then expands on soul-level diagnostic groupings, including DTC inspection priority charts, fail-safe references, and diagnostic logic for efficient fault isolation. Symptom charts and diagnostic pathways support deeper technical understanding of complex automatic shift behaviors.

A/T Shift Lock & Circuit Logic

Shift lock and related circuit elements are grouped in a way that shows how electrical and mechanical control systems interact. This includes wiring diagrams, control logic, and component inspection references that connect transaxle behavior with electronic systems.

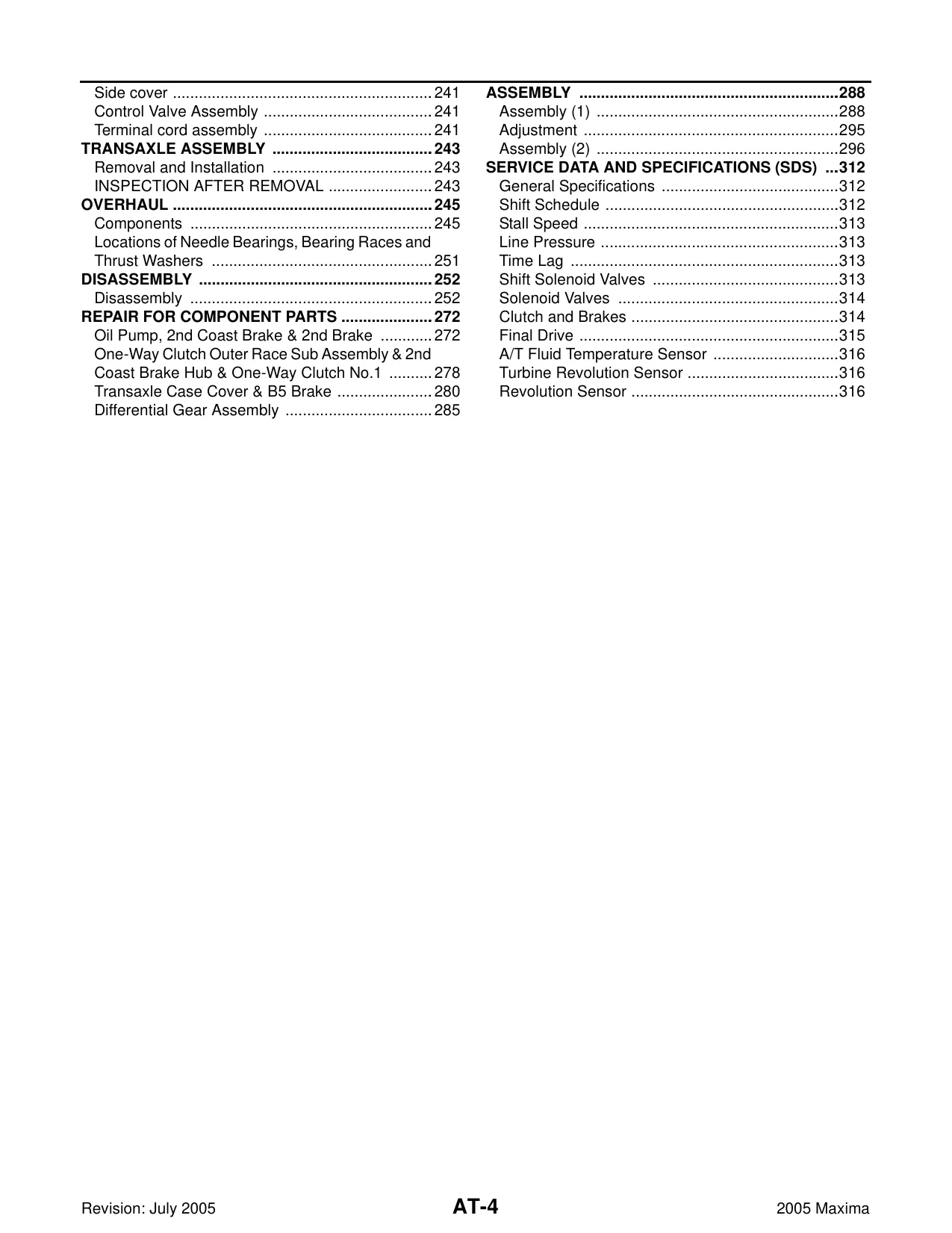

Transaxle Assembly, Overhaul & Service Data

The manual provides structured references for on-vehicle service procedures, complete transaxle assembly removal and installation, overhaul breakdowns, and component-level grouping for clutches, gears, bearings, and brake assemblies within the transaxle. Service data and specifications include shift schedules, line pressure values, stall speed references, and solenoid performance tables.

When This Manual Fits Best

This automatic transaxle manual is an excellent choice if you want a full-scope technical reference for the Nissan Maxima’s automatic transmission systems spanning model years 2004–2009. It’s especially valuable for professional technicians, transmission specialists, and owners who prioritize detailed, factory-aligned documentation over fragmented or partial resources.

Digital Format & Access

Delivered as a downloadable ZIP package with printable PDF content, this manual is ready for immediate access and long-term archival use. Its structured layout supports efficient lookup and repeated reference throughout the vehicle’s service life.

FAQ

Customer Reviews

Read what our customers say about this Nissan Car manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)