Case 580 Super K Loader Backhoe Service Manual

Case 580 Super K technical guide detailing common maintenance and repair procedures. Includes troubleshooting and specifications. PN JJG0160001+.

Manual Preview

Sample pages from the Case 580 Super K Loader Backhoe Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Case 580 Super K Loader Backhoe (JJG0160001+) - Service Manual | Workshop Ready Service-Catalog Case 580 Super K Loader Backhoe (JJG0160001+) -- 1992-1996 Engine & Drive Sourcebook | Repository

- Engine Power Specs: 85 hp at 2330 RPM establishes the maximum power output Capability.

- Engine Cooling System: For optimal operation, 17.2 quarts defines the coolant capacity Framework.

- Hydraulic System: The reservoir capacity requires 21.5 quarts -- signifies the total fluid volume Threshold.

- Transmission: The power shuttle transmission requires 47.6 quarts for standard operation Logic.

- Max PTO Torque: Engine speeds reach 2200 RPM Parameters.

- Fuel Capacity: 25 gallons is the standard fuel tank capacity Configuration.

Professional Workshop Service Manual & Technical Specifications

Case 580 Super K Loader Backhoe Essential Case 580 Super K Loader Backhoe Service Manual (JJG0160001+) 700+ Pages | Workshop Ready Service-Catalog

| Component-Focus: Engines // Technical-Scope: 1248 Pages / 4-390 Diesel Engine Logic // System-Identifier: Lubrication System. | Integrated-Framework | Baseline | Calibration-Data |

|---|---|---|---|

| Engine Specifications | 102.00-102.04 mm | 0.038 mm | |

| Piston Ring Specs | 0.25-0.55 mm | 0.15 mm | |

| Crankshaft Journals | 68.987-69.013 mm | 0.050 mm | |

| Valve Specs | 7.960-7.980 mm | 0.038 mm | |

| Oil Pump Clearance | 0.178 mm | - | |

| Turbocharger Movement | 0.10-0.16 mm | - |

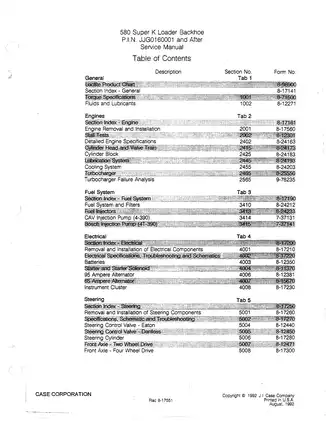

Integrated service sections encompass:

Engine Removal and Installation

Torque Specifications - Decimal Hardware

Fluids and Lubricants

Engine Oil Recommendations

Diesel Fuel

Reliably demanding.

FAQ

Customer Reviews

Read what our customers say about this Case Backhoe Loader manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)