Stihl MS 341, MS 361 chainsaw service manual/parts list

Manual Preview

Sample pages from the Stihl MS 341, MS 361 chainsaw service manual/parts list manual

Purchase & Download

Models Covered & Key Technical Specifications

-

STIHL MS 341, MS 361 (1135 Series) — [2003–2012] Secure Repository ◊ MS 341, MS 361, MS 361 C, MS 361 C-B, MS 361 C-M, MS 361 C-Q, MS 361-W, MS 361-VW Mid-Range Professional Library (Archive-Standard).

-

Advanced Parameter: 13,500 rpm establishes the maximum permissible engine speed with bar and chain installed.

-

Specific Measurement: 0.5 mm is required for the electrode gap of the spark plug to ensure reliable ignition.

-

Technical Data-Point: 0.44 kW defines the heating power for the carburetor heating system on V-variants.

-

Essential Rating: 0.2–0.4 mm must be maintained as the air gap between the ignition module and the flywheel.

-

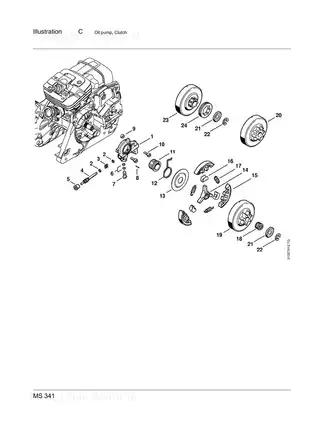

Core Limit: 0.65 mm signifies the maximum permissible wear limit for the clutch shoes before replacement.

Professional Workshop Service Manual & Technical Specifications

Integrated Technical Manual Reference: STIHL MS 341 / MS 361 Series

STIHL MS 341, MS 361 (1135 Series) — [2003–2012] Manual-Nexus

Precise Methodology

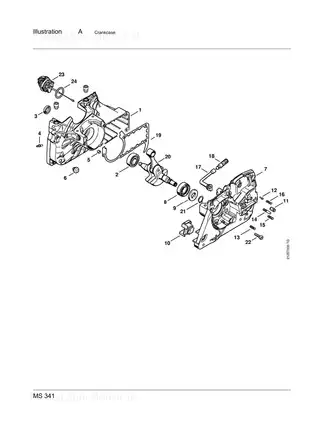

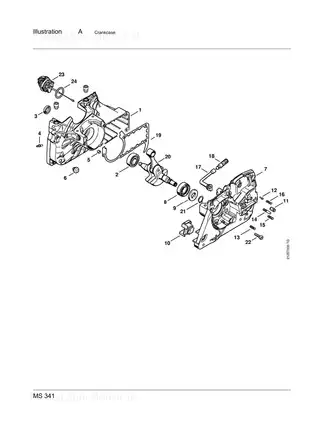

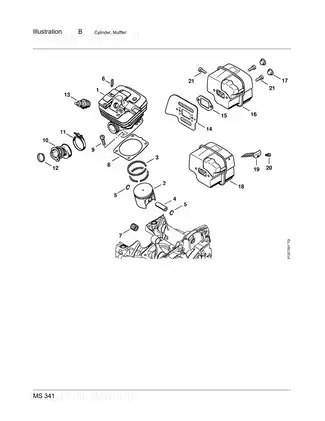

Within the assembly architecture, specific service protocols delineate the interface between the power unit and the drive components. To ensure system alignment, the documentation outlines structural requirements for the crankcase and cylinder assembly without deviating from established factory standards. Proper handling of specialized adjustment tools remains a prerequisite for technicians interacting with the ignition and carburetor systems. Governing operational sequences, the provided framework emphasizes the importance of utilizing original components for all maintenance-related activities. Maintaining structural integrity relies upon adhering to the designated sequence for mechanical disassembly as defined by the manufacturer.

Technical Parameters

| Component Category | System Groupings | Document Scope Areas |

|---|---|---|

| Power Plant | Engine Housing & Cylinder Unit | Internal Combustion & Compression Logic |

| Fuel Management | Carburetion & Tank Ventilation | Air/Fuel Ratio Control Framework |

| Safety Systems | Chain Brake & Hand Guard | Inertia-Activated Protection Sequences |

| Ignition Group | Flywheel & Module Interface | Electrical Timing & Spark Generation |

| Auxiliary Units | Oil Pump & Tensioning Hardware | Lubrication & Cutting Interface |

Systematic Nexus

By referencing the manufacturer-defined specifications, qualified personnel can identify the precise relationship between the centrifugal clutch and the chain drive mechanism. To facilitate effective troubleshooting, the architecture organizes electrical and mechanical components into distinct functional blocks. Rigorously validating system logic ensures that all safety-critical interfaces operate within the intended design parameters. Professional execution of repair tasks necessitates a comprehensive understanding of the specialized pullers and mounting tools described within the repository. Operational limits follow OEM-defined parameters to safeguard the longevity and reliability of the professional-grade equipment.

FAQ

Customer Reviews

Read what our customers say about this Stihl Chainsaw manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)