2000 John Deere 240 / 250 Skid Steer Technical Manual

Technical reference spanning John Deere 240 and 250 Skid Steers, covering engine, fuel system, electrical, and more. Ref: TM1747 (Nov00)

Manual Preview

Sample pages from the 2000 John Deere 240 / 250 Skid Steer Technical Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

John Deere 240 & 250 Skid Steer Technical Manual: John Deere 240 & 250 Skid Steers - TM1747 Model-Designation: John Deere 240 / John Deere 250 (TM1747) | Machine-Range: 2000 | Unit-Designations: Skid Steer Loaders

- Published Speed Rating: 11.7 km/h establishes the maximum operational capability.

- Specific Travel Rate: For efficient movement, 11.7 km/h is the specified top speed.

- Integral Net Mass: 2811 kg -- signifies the base operating weight.

- Operational Assembly Torques: The cylinder head requires 150 N-m for proper tightening.

- Established Adjustment Range: The valve clearance sets at 0.31-0.38 mm for intake valve operation.

- Authorized Cold Start Limits: For reliable cold weather operation, the engine coolant temperature must be maintained above -40°C.

Professional Workshop Service Manual & Technical Specifications

John Deere 240 & 250 Skid Steer Technical Manual: John Deere 240 & 250 Skid Steers - TM1747

Model-Designation: John Deere 240 / John Deere 250 (TM1747) // Machine-Range: 2000 / Unit-Designations: Skid Steer Loaders

| Assessment-Element | Value | Context |

|---|---|---|

| Cylinder Head Thickness | 104.87–105.13 mm | New part dimension specification. |

| Max Permissible Out-of-Flat | 0.08 mm | Cylinder head sealing surface tolerance. |

| Intake Valve Stem Diameter | 7.864–7.884 mm | Standard dimension for proper valve function. |

| Exhaust Valve Seat Angle | 29.25 ± 0.25° | Specified angle for intake and exhaust valve seating. |

| Piston Protrusion | Not to exceed 0.25 mm | Measurement critical for engine timing. |

| Crankshaft Journal OD | 79.324–79.350 mm | Standard dimension for crankshaft journals. |

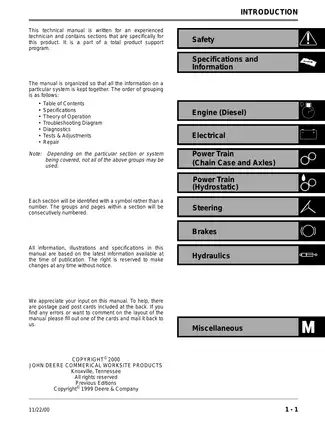

Maintenance hierarchies are structured into the following sections:

Engine Specifications

This section details crucial engine parameters such as bore, stroke, displacement, and compression ratio. It includes specifications for lubrication, air cleaner, and cooling systems, ensuring optimal engine performance.

Fuel and Electrical Systems

Covers specifications for the fuel system, including fuel type and delivery, and the electrical system, detailing battery type and charging system specifics for reliable operation.

Hydraulics and Hydrostatics

Provides detailed specifications for the hydraulic system, including pump types, displacement, relief pressures, and system capacities, essential for understanding machine operation.

Dimensions and Tires

Details the physical dimensions of the John Deere 240 and 250 skid steers, along with tire specifications, critical for understanding machine footprint and load bearing.

Recommended Lubricants

Lists recommended lubricants for various components, including engine oil, coolant, hydraulic oil, grease, and chain case oil, vital for maintenance and longevity.

This manual documents torque specifications for critical components to ensure proper structural misalignment prevention. It also includes operating procedures for various systems like the transmission, hydraulics, and engine.

FAQ

Customer Reviews

Read what our customers say about this John Deere Skid Steer Loader manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)