2003 Honda ST1300/ST1300A Pan European Service Manual

Factory PGM-FI fuel injection diagnostics, ABS brake modulator troubleshooting, and complete transmission/suspension service procedures for this 1261cc V-twin touring motorcycle. 632 pages.

Manual Preview

Sample pages from the 2003 Honda ST1300/ST1300A Pan European Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Honda ST1300/ST1300A Pan European — 2003 Comprehensive Operational Reference | ST1300 Series Archive.

- Calibrated Displacement Data: 1261 cm³ (76.9 cu-in) is established at the engine cylinder volume Topology.

- Nominal Bore and Stroke Specification: For engineering precision, 78.0 × 66.0 mm (3.07 × 2.60 in) specifies the piston travel dimensions Standards.

- Advanced Compression Ratio: 10.8:1 — represents the combustion chamber pressure configuration Matrix.

- Documented Engine Oil Capacity: The crankcase requires 3.6 liter (3.8 US qt, 3.2 Imp qt) after complete draining Protocol.

- Principal Fuel Tank Capacity: Tank volume reaches 29 liter (7.7 US gal, 6.4 Imp gal) for extended range Bounds.

- Key Cooling System Capacity: Radiator and engine coolant reaches 2.66 liter (2.81 US qt, 2.34 Imp qt) full specification Margin.

Professional Workshop Service Manual & Technical Specifications

Operational Diagnostic Factory Manual: Motorcycle 2003 Honda ST1300 and ST1300A Pan European - Factory-Grade Service Manual for Touring Motorcycle Maintenance & Repair Parts-Reference

Maintenance-Category: 2003 Honda ST1300, Honda ST1300A, Honda Pan European // Procedure-Type: Technical-Diagnostic-Operations / Component-Level Service Logic // Engineering-Metrics: Parametric-Data-Documentation, Multi-System Coverage, Factory-Specifications.

| Performance-Element | Technical-Path | Context |

|---|---|---|

| Fuel Injection System | PGM-FI Configuration & Sensor Integration | Complete electrical schematics and component locations documented |

| Engine & Drivetrain | Cylinder Head, Clutch, Transmission, Crankshaft Assembly | Full specifications with service limits and inspection procedures included |

| Hydraulic Systems | Brake, Clutch, ABS Modulation | Pressure specifications, fluid requirements, and bleeding procedures documented |

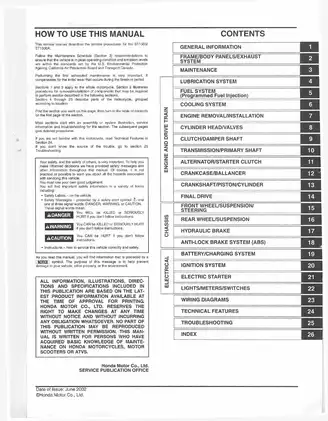

Providing a structural breakdown of the 2003 Honda ST1300/ST1300A service manual encompasses comprehensive systems, covers both the ST1300 and ST1300A platforms, traces frame and suspension configurations, and documents electrical architecture. The publication delivers maintenance schedules synchronized with factory intervals, presents troubleshooting matrices for PGM-FI self-diagnostics, examines cooling and lubrication subsystems, and includes wiring diagrams for complete motorcycle circuitry.

Structured Framework

Parts identification is covered for frame body panels, exhaust systems, windscreen assemblies, and seat rail configurations. The document encompasses component location illustrations showing alternator placement, fuel pump positioning, sensor arrays, and relay arrangements. Detailed removal and installation sequences address trim clips, saddlebags, cowl assemblies, mirrors, and body panel fastening procedures. Specifications for torque values across engine mounting bolts, frame attachment points, and suspension components appear throughout the manual's technical tables.

Diagnostic Topology

Removal procedures are documented for clutch assemblies, transmission shafts, crankshaft components, cylinder head structures, and valve train configurations. The manual provides step-by-step extraction and reinstallation sequences for the PGM-FI fuel injection system, including fuel pump units, pressure regulators, throttle body assemblies, and injector rail configurations. Service procedures address oil pump disassembly, oil strainer cleaning, relief valve inspection, and cooler installation protocols. Brake system component removal covers master cylinders, calipers, pad replacement, and ABS modulator extraction.

Modular Protocol

Technical specifications are provided for the 90° V-twin engine displacing 1261 cc with 10.8:1 compression, DOHC chain-driven valve train configuration, and forced pressure lubrication system. Valve clearance reference data is included (intake 0.16 + 0.03 mm, exhaust 0.25 + 0.03 mm). Engine oil specifications document Honda GN4 or HP4 4-stroke oil requirements with SAE 10W-40 viscosity and 3.6-4.7 liter capacity depending on service type. Cylinder compression ranges, bearing clearances, piston dimensions, and connecting rod specifications appear in detailed measurement tables.

Advanced Parameters

Factory specifications are documented for transmission gear ratios (five-speed constant mesh), final drive reduction (2.833:1), and clutch system hydraulic operation. Cooling system capacity encompasses 2.66 liters radiator volume plus 0.865 liters reserve tank, with thermostat opening at 80-84°C and full valve lift at 8 mm minimum. Fuel system specifications include PGM-FI throttle bore diameter (36 mm), fuel pressure at idle (343 kPa), and fuel pump flow (180 cm³ minimum per 10 seconds). Tire specifications reference 120/70 ZR 18 front and 170/60 ZR 17 rear Bridgestone or Dunlop compounds with 290 kPa cold pressure settings for standard and deluxe models.

Strategic Benchmarks

Engine rebuild procedures are documented for camshaft installation with molybdenum disulfide lubrication applied to lobes and journals. The manual documents torque specifications for the connecting rod bearing cap nuts (35 N-m), cylinder head flange bolts (69 N-m), primary drive gear assembly (93 N-m), and final drive special nut (186 N-m) to ensure proper component assembly and flange face sealing. Fuel system self-diagnostic procedures reference ECM failure codes 0-33, malfunction indicator lamp (MIL) blink sequences, and peak voltage inspection protocols for ignition and cam pulse generators. ABS modulator mounting, front and rear wheel pulser ring installation, and proportional control valve assembly appear in chassis service sections.

Emission control systems are fully described including PGM-FI fuel management, PAIR (Pulse Secondary Air Injection) reed valve operation, catalytic converter arrangement, and EVAP canister purge control solenoid valve function. Secondary air supply introduces filtered air at exhaust ports to promote unburned gas oxidation. The document includes vacuum hose routing diagrams, emission control information labels, and evaporative family classifications relevant to California Air Resources Board compliance standards.

FAQ

Customer Reviews

Read what our customers say about this Honda Motorcycle manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)