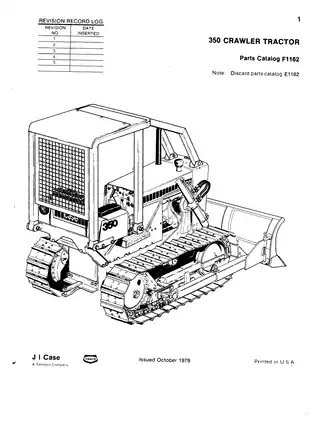

1979 Case 350 Crawler Tractor Parts Catalog

Complete illustrated parts list with part numbers. Comprehensive reference for all tractor components and assemblies. Part catalog F1162 covers engine, transmission, hydraulics, track, and attachments. Essential documentation for Case 350 crawler models.

Manual Preview

Sample pages from the 1979 Case 350 Crawler Tractor Parts Catalog manual

Purchase & Download

Models Covered & Key Technical Specifications

Case 350 Crawler Tractor — 1979 Technical Service Archive | 350 Series Repository.

- Documented System Fill: 188 diesel engine displacement reaches 5.75 L (351 cu in) representing the main power unit Specifications.

- Measured Hydraulic Capacity: For equipment operation, 17 L (4.5 gal) defines the shuttle transmission reservoir volume Baseline.

- Universal Pressure Rating: Hydraulic relief valve setting is standardized to 2070 kPa (300 psi) system threshold Mapping.

- Core Torque Data: Cylinder head bolts corresponds to 1/2 x 5-5/8" NC fastening 12 point head Configuration.

- Rated Track Assembly: Sealed track chain yields 33-unit or 16-17 unit link configurations per design Requirements.

- Prescribed Fuel Tank: Engine fuel storage is established at 50 L (13.2 US gal) capacity Parameters.

Professional Workshop Service Manual & Technical Specifications

Strategic Repair Reference Manual: Crawler Case 350 Crawler Tractor Parts Catalog (F1162) - Comprehensive Guide 1979 Technical-Guide

Technical-Benchmarks: JiCase 350 Crawler Tractor (1979) // Operational-Framework: Parts identification and component systems // Technical-Benchmarks: 499 pages with detailed assembly diagrams and cross-references.

| Integrated-Framework | Value | Architecture |

|---|---|---|

| Document Scope | Parts catalog with component listings | Comprehensive parts identification system |

| Engine Documentation | 188 diesel engine specifications | Complete engine and drive system components |

| Hydraulic Systems | Equipment and attachment circuits | Full hydraulic component documentation |

| Track Assembly | Undercarriage and mobility systems | Track shoes, rollers, and frame components |

Coverage is segmented into engine and transmission systems, hydraulic circuits for loader and dozer attachments, track assembly and undercarriage documentation, electrical system components and wiring, and final drive and differential assemblies. The manual comprises intake and exhaust manifolds, cylinder head and valve mechanism specifications, fuel injection system and filter documentation, cooling system and water pump reference, timing gear cover and camshaft assemblies, and crankshaft and piston component identification.

Core Benchmarks

Component locations are identified for engine mounting, generator and alternator assemblies, starter motor configurations, and battery electrical system layout. The document references engine serial number variations affecting fuel filter types, injection pump drives, and cooling system modifications across production dates. Torque converter, shuttle transmission, and power shuttle components occupy substantial documentation sections with detailed breakdowns of clutch assemblies, gear arrangements, and valve configurations.

Advanced Architecture

Service procedures are documented for track roller types including standard, heavy-duty, and face-seal configurations. The manual provides complete undercarriage component listings encompassing track chains, shoes in multiple groove patterns and materials, idler wheels with sealed and non-sealed options, track guides, and hydraulic track adjusters. Loader hydraulic circuits include lift cylinder assemblies, bucket tilt systems, hydra-leveling mechanisms, and grapple attachments with detailed component specifications.

Structured Threshold

Calibration requirements are specified for hydraulic pump types used across production serial numbers, with notation of Hydreco and Cessna pump variations. Dozer hydraulic systems are documented for mechanical angling, power angling, power tilt, and power angle-tilt blade configurations. Ripper hydraulic circuits appear with and without diversion valve configurations, and three-point hitch systems reference multiple control valve applications.

Modular Threshold

Electrical system documentation covers generator models including ventilated types (Delco-Remy), enclosed type assemblies, and alternator installations with voltage regulator components. Starter motor options document multiple configurations with different tooth drive pinion counts. Instrument panel layouts differ between generator and alternator equipped machines, incorporating gauges, switches, hourmeter assemblies, and circuit protection devices.

Advanced Nexus

Suspension service documentation covers differential and brake assemblies with planetary gear systems, sun gears, and brake band configurations. Cylinder identification for various attachment types references split piston designs, solid rod wipers, and gland configurations with identification markings. The manual documents torque specifications for hydraulic component fasteners to ensure proper assembly integration across multiple attachment systems.

FAQ

Customer Reviews

Read what our customers say about this Case Crawler manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)