1978-1987 John Deere 670A/672A Motor Grader Repair Manual

Detailed service data for John Deere 670A/672A Motor Graders, covering engine, transmission, hydraulics, and more. Publication TM-1188.

Manual Preview

Sample pages from the 1978-1987 John Deere 670A/672A Motor Grader Repair Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Precision Operations Manual: John Deere 670A/672A Motor Grader Full Technical Manual (1978-1987) – 270 Pages | OEM Specs Factory-Standards John Deere 670A / John Deere 672A (1978-1987) | TM-1188 Compendium

- Approved Weight Data: 25,980 lb to 30,675 lb based on configuration and tires.

- Baseline Net Mass: 125 hp (93.2 kW) establishes the baseline net engine flywheel power rating.

- Verified Output Density: 414 cu. in. (6784 cm 3) signifies the piston displacement for efficient operation Framework.

- Designated Capacity Limits: 7 gal (26.5 L) is the specified cooling system capacity for sustained performance Logic.

- Certified Energy Draw: 24 volt systems are utilized for the main electrical operations Standards.

- Reference Angular Speed: 2300 RPM is the standard operating speed for the engine Metrics.

Professional Workshop Service Manual & Technical Specifications

Precision Operations Manual: John Deere 670A/672A Motor Grader Full Technical Manual (1978-1987) – 270 Pages | OEM Specs Factory-Standards

Series-Validation: 1978-1987 | Conceptual-Layout: Motor Grader / Tractor Chassis Logic | Specification-Class: Technical Manual.

The service manual covers the entire operation, maintenance, and repair of the John Deere 670A and 672A Motor Graders. It provides comprehensive information for technicians and owners alike, ensuring proper upkeep and functionality. This document is an essential resource for anyone working with these powerful machines, offering detailed guidance on all aspects of their mechanical systems.

Systems Overview

Fundamentally establishing the operational parameters, this manual includes detailed sections on hydraulic schematics, steering systems, and braking mechanisms. It covers the complex interplay of these systems to ensure efficient and safe operation. The manual also delves into the electrical system and engine auxiliary systems, providing a holistic view of the grader's capabilities.

Procedures and Components

Repair and maintenance procedures are meticulously outlined, covering everything from major overhauls to routine servicing. Specific guidance is provided for the transmission, axles, suspension, and ground conditioning tools. The document also details the operation and maintenance of the grading and lifting mechanisms, offering clear instructions for adjustments and repairs.

Specifications and Diagrams

This manual provides extensive technical specifications, including engine details, power transmission configurations, and hydraulic system markers. It also contains detailed diagrams and illustrations that aid in understanding the various components and their assembly. Crucially, it includes comprehensive information on torque specifications for numerous parts to ensure proper clamp load consistency and mechanical integrity.

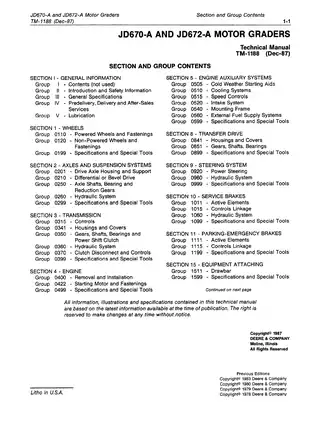

Table of Contents Summary The service manual covers:

- General Information and Specifications

- Wheels and Axles

- Transmission Systems

- Engine and Auxiliary Systems

- Hydraulic Systems

- Ground Conditioning Tools

Maintenance and Troubleshooting

The manual details the necessary steps for routine maintenance, such as lubrication schedules and fluid level checks. It also provides guidance on troubleshooting common issues, helping to diagnose and resolve problems efficiently. This structured approach ensures that the grader remains in optimal working condition, minimizing downtime and maximizing productivity.

FAQ

Customer Reviews

Read what our customers say about this John Deere Motor Grader manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)