2008 Evinrude/Johnson HP 115, 150, 175, 200 Outboard Service Manual

Diagnostic procedures and component service for Evinrude/Johnson HP 115, 150, 175, 200 outboards. PN 5005844

Manual Preview

Sample pages from the 2008 Evinrude/Johnson HP 115, 150, 175, 200 Outboard Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

2008 Evinrude/Johnson HP 115, 150, 175, 200 Outboard Service Manual Diagnostic procedures and component service for Evinrude/Johnson HP 115, 150, 175, 200 outboards. PN 5005844 | Service Manual Set

- Authorized Diagnostic Data: 30 VDC provides the essential diagnostic voltage for the EMM.

- Specific Temperature Range: For optimal operation, 176°F (80°C) defines the critical EMM temperature limit Framework.

- Operational Pressure Limit: 21 psi minimum @ 3000 RPM signifies the required minimum water pressure Threshold.

- Advanced Ignition Timing: The EMM controls the timing pointer to ensure proper synchronization Logic.

- Fundamental Fuel Delivery: Fuel injectors are electronically controlled by the EMM to ensure optimal performance Parameters.

- Maximum Engine Speed: RPM Limit restricts operation to 6250 RPM to prevent engine damage Baseline.

Professional Workshop Service Manual & Technical Specifications

Complete Repair Workshop Manual: Evinrude/Johnson Outboard Service Manual (2008) - HP 115, 150, 175, 200 Procedure-Library

Model-Specs: E115DPLSCR, E150HPLSCR, E175DPLSCR, E200DPLSCR, E115DSLSCR, E150DSLSCR, E175DSLSCR, E200DSLSCA, E115DBXSCR, E150DBXSCR, E175DPXSCR, E200DPXSCA, E115DPXSCR, E150DPXSCR, E175DPXSCF, E200DPXSCF, E115DCXSCS, E150DCXSCR, E175DCXSCR, E200DCXSCA, E150DCXSCF, E175DCXSCF, E200DCXSCF // Series-Validation: Evinrude E-TEC Outboard / Service Manual // Architecture-Focus: 60° V4 / V6 Engine Architecture

| Identifier | Parameters | Validation-Data |

|---|---|---|

| Engine Type | 60° V 4-Cylinder Loop-Charged | 60° V 6-Cylinder Loop-Charged |

| Displacement | 105.4 cu. in. (1727 cm³) | 158.2 cu. in. (2592 cm³) |

| Standard Bore | 3.6005 to 3.6015 in. (91.45 to 91.48 mm) | 3.601 in (91.47 mm) |

| Stroke | 2.588 in. (65.74 mm) | 2.588 in. (65.74 mm) |

| Rod Crankpin | 1.3757 to 1.3762 in. (34.94 to 34.96 mm) | 1.3757 to 1.3762 in. (34.94 to 34.96 mm) |

| Piston Ring End Gap | 0.011 to 0.023 in. (0.28 to 0.58 mm) | 0.011 to 0.023 in. (0.28 to 0.58 mm) |

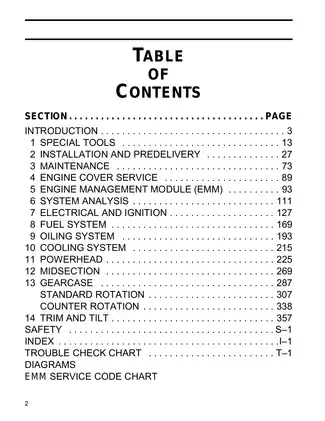

Repair procedures are structured around a clear, systematic approach to diagnose and repair all systems. This manual details procedures for the Engine Management Module (EMM), fuel system, ignition system, starter system, and lubrication systems. It includes diagnostic information, troubleshooting tips, and component-specific service instructions. It also covers pre-season checks, maintenance schedules, and guidelines for handling submerged engines, ensuring a comprehensive resource for technicians.

Engine Management Module (EMM) Systems

This section covers the functions of the EMM and its various internal and external sensors, including diagnostic software usage, troubleshooting procedures, and EMM LED indicators. It details system voltage tests, ignition tests, and fuel system tests.

Fuel System Components and Tests

It details fuel system components such as the fuel lift pump, fuel filter, vapor separator, fuel circulation pump, fuel supply and return manifolds, and fuel injectors. Specific tests include fuel system pressure, injector resistance, lift pump pressure, and vacuum tests, as well as anti-siphon valve and vapor separator vent checks.

Ignition System Diagnostics

This manual provides detailed procedures for testing ignition system components, including crankshaft position sensor, throttle position sensor, stator tests, and ignition coil tests. It covers static and running ignition tests, as well as troubleshooting for no spark or erratic spark conditions.

Starter System Service

It outlines the steps for starter removal, disassembly, cleaning, inspection, and assembly. This includes procedures for servicing the starter solenoid, checking current draw, and installing the starter motor.

Oiling System Components and Tests

This section details the oil tank assembly, oil injection pump, oil pressure sensor, and electrical circuits. It covers oil priming, oiling rates, break-in oiling, and specific tests for the oil injection pump and low oil sending unit.

FAQ

Customer Reviews

Read what our customers say about this Evinrude Outboard Motor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)