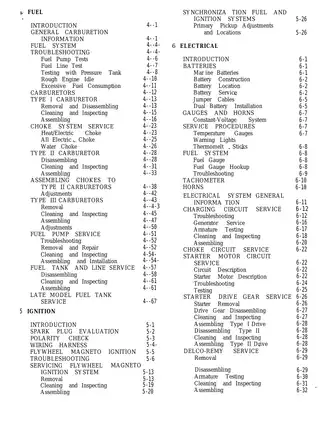

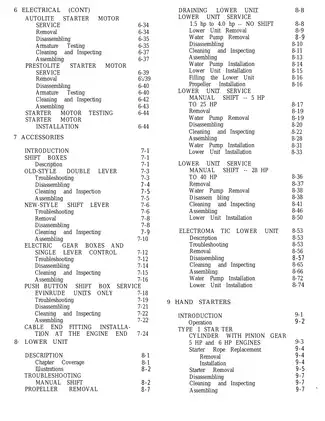

1956-1972 Evinrude Johnson 1.5-40 hp Outboard Workshop Manual

This comprehensive service manual for Evinrude Johnson 1.5-40 hp outboards (1956-1972) offers detailed repair procedures and specifications. PN 58014-8.

Manual Preview

Sample pages from the 1956-1972 Evinrude Johnson 1.5-40 hp Outboard Workshop Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

Unified Service Technical Manual: Outboard Motor Official Evinrude Johnson 1.5–40 hp Outboard Workshop Manual (1956–1972) – 417 Pages | Factory Grade Workshop-Compendium Evinrude Johnson Outboard Series (1956–1972) — Series: 00000. Automotive Resource Documentation Kit.

- General Rotation Data: 783 rpm corresponds to the minimum speed parameters.

- Design Shipping Weight: For 1.5 hp models, 45 lbs defines the typical unit weight Framework.

- Engine Lubrication Specifications: The formatter board requires 73-3/4 inches for standard operation Logic.

- Factory Fuel System: The fuel line requires specific fuel pump connections Standards.

- Verified Wattage Specs: 40 hp signifies the maximum engine output Threshold.

- Certified Fluid Levels: For correct operation, 10W oil is the specified lubrication Protocol.

Professional Workshop Service Manual & Technical Specifications

Unified Service Technical Manual: Outboard Motor Official Evinrude Johnson 1.5–40 hp Outboard Workshop Manual (1956–1972) – 417 Pages | Factory Grade Workshop-Compendium

Technical-Scope: Evinrude Johnson Outboard Series (1956–1972) // Engine-Type: Two-cycle engine architectures // Operational-Framework: 1.5–40 hp Outboard Workshop Manual

| Identifier | Value | Calibration-Spec |

|---|---|---|

| Two-cycle engine operation | 73-3/4 to 75-3/4 inches | as specified in Appendix A-15 |

| Fuel Delivery | Carburetor choke solenoid | White and green wire lead configurations |

| Ignition System | Flywheel magneto | Specific serial number identification |

| Carburetor | Type I, II, and III | With manual, heat/electric, or water choke |

| Lower Unit | Manual Shift | With different gear oil capacities |

| Tune-up | Minor & Major | Based on 20-hour and 80°F rating |

Systematizing the service groups into comprehensive chapters, this manual covers all aspects of your Evinrude Johnson outboard motor. From basic safety and tune-up procedures to detailed breakdowns of the powerhead, fuel system, ignition, and electrical systems, this document provides the necessary information for proper maintenance and repair.

Fuel system components and their functions are clearly outlined, including the fuel tank, fuel pump, and carburetor systems. Discussions cover fuel flow principles, float systems, and detailed instructions for various carburetor types.

Ignition system principles are explained, covering flywheel magneto ignition, spark plug evaluation, and wiring harness checks. Troubleshooting tips for common ignition issues are also provided.

Electrical system components such as batteries, gauges, horns, and the starting system are detailed. Service procedures for battery testing, charging, and maintenance are included.

This manual documents torque specifications for critical engine components to ensure proper assembly and performance. Adhering to these specifications is essential for maintaining the integrity of the engine and preventing damage. Clearance measurements are addressed for essential engine parts, detailing the necessary steps to ensure correct assembly and function. The manual guides users through these procedures to guarantee optimal engine performance and longevity. Special procedures are addressed for specific engine components, ensuring that even complex tasks are explained in a way that is easy to understand and follow. Verification procedures are included for critical adjustments and installations, providing a step-by-step guide to confirm that all work has been completed correctly. Repair information is provided for common issues and wear components, ensuring that users can effectively diagnose and fix problems to keep their engines running smoothly. The document includes coverage of the engine's operational framework, detailing how different systems interact to produce power and maintain performance.

FAQ

Customer Reviews

Read what our customers say about this Evinrude Outboard Motor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)