Rotax 655/95 Engine Repair Manual

Complete service data for Rotax 655/95 engine featuring technical specs, maintenance schedules, and precision diagnostics for professional repair and overhaul procedures.

Manual Preview

Sample pages from the Rotax 655/95 Engine Repair Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

ROTAX Type 655/95 — 1995–2000 Documentary Sourcebook | 655/95 Series Edition.

- Established Amperage Specs: The generator system is measured at 12V 280W output capacity Matrix.

- Operational Thermal Envelope: For cooling system function, liquid coolant circulation maintains operation between 15–35°C operating bounds Standards.

- Certified Production Rate: Engine displacement is set to 651.88 cc (cubic centimeters) representing total swept volume Margin.

- Factory Imaging Specs: Maximum horsepower output limits 34 kW at 6750 rpm defines peak engine performance Protocol.

- Approved Fluid Capacity: Peak torque output is established at 56 Nm (41 lb-ft) at 5500 rpm Architecture.

- Measured Output Rating: Idle speed controls 1400 rpm for baseline engine operation Norms.

Professional Workshop Service Manual & Technical Specifications

Comprehensive Procedure Field Manual: Engines (Gasoline) Official Rotax Type 655 Engine Repair Manual - Precision Diagnostics & Maintenance Procedures Standards-Vault

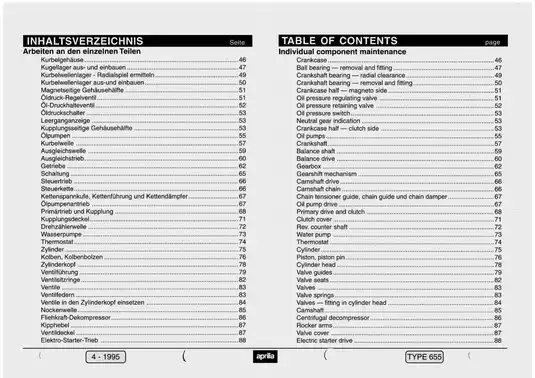

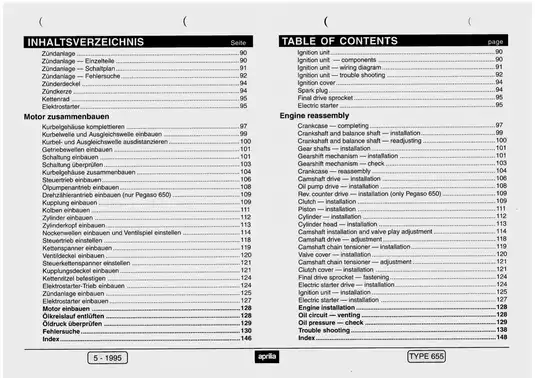

Engineering-Metrics: ROTAX Type 655/95 four-stroke air-cooled engine // Component-Focus: Engine disassembly, reassembly, maintenance procedures / Crankcase, valve train, fuel and ignition systems Logic // Engineering-Metrics: 149 pages, bilingual German-English technical documentation.

| Identifier | Technical-Path | Framework |

|---|---|---|

| 1. Disassembly & Removal | Complete step sequences for engine extraction from frame through component separation | Documented |

| 2. Individual Component Service | Bearing maintenance, seal replacement, wear measurement protocols | Complete specifications provided |

| 3. Reassembly Procedures | Systematic crankcase completion, shaft installation, torque protocols | See Chapter X |

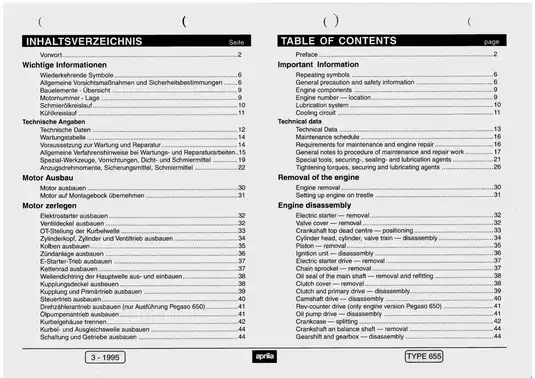

The repository is divided into major sections encompassing engine removal and preliminary preparation, followed by sequential disassembly of the crankcase halves, valve train, and transmission components. The manual then proceeds through detailed maintenance of individual elements including camshaft drive systems, oil pump mechanisms, and primary clutch assemblies. Reassembly instructions work in reverse sequence to disassembly, with special emphasis on dimensional checks and clearance verification between major component interfaces.

Advanced Sequences

Effectively requiring thorough understanding of fastener locations and torque application, the document provides structured guidance for removing the engine from the motorcycle frame and securing it on a workshop trestle. Reference data is included for all fastening hardware, both threaded connections and retaining rings, ensuring proper assembly during reinstallation phases. The manual covers systematic progression from external component removal through complete crankcase separation, documenting each withdrawal sequence to prevent binding or component damage.

Advanced Threshold

This manual covers detailed procedures for crankshaft and balance shaft removal, including precision measurement protocols for radial clearance determination. Diagnostic procedures are covered for identifying wear conditions in bearing journals, evaluating proper oil supply routing through internal galleries, and assessing internal centrifugal filtering systems. Wiring diagrams are provided for the breakerless capacitor-discharge ignition unit, displaying generator connections, trigger sensor placement, and emergency shutoff circuit logic. The technical content emphasizes wear limit specifications with dimensional tolerances, requiring micrometrical verification before component reinstallation.

Comprehensive Threshold

Fuel system procedures are documented for carburetor integration and engine control linkage alignment. The manual provides comprehensive coverage of the liquid cooling system including thermostat operation, water pump drive mechanics, and coolant circulation pathways through integrated passages within the cylinder head and block structure. Photographs and exploded diagrams illustrate component positioning at critical assembly stages, particularly where multiple parts interface at shared mounting surfaces.

Engineered Nexus

This manual documents torque specifications for the crankshaft fasteners to ensure proper cone joint separation prevention. Oil pump specifications address dual-stage flow routing through pressure regulators and sump return filtration, with numbered passage identification correlating to internal gallery locations within the crankcase halves. Special tools and insertion fixtures are catalogued with their ROTAX part numbers, essential for bearing press-fitting and seal installation without component damage.

Modular Logic-Path

The troubleshooting section covers symptom-based diagnosis across engine starting, idle stability, power delivery, thermal management, and audible fault identification. Each trouble condition lists probable causes ranked by frequency and provides systematic remedy sequences. Content addresses electrical system diagnostics using resistance measurement protocols, mechanical wear indicators with failure progression timelines, and fluid condition assessment parameters.

The document includes complete specifications for motor oil viscosity grades, antifreeze mixture ratios for the cooling system, and fuel octane requirements. Component clearance data is provided for piston-to-bore fit, crankshaft journal play measurement, and camshaft bearing preload determination using precision gauge methods. Maintenance intervals are tabulated with service task descriptions and distance-based scheduling recommendations, enabling systematic upkeep planning for operating vehicles.

FAQ

Customer Reviews

Read what our customers say about this Rotax Engines (Gasoline) manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)