2001 Aprilia Rotax 120/154/177 Workshop Manual (140 P.)

Timing chain, valve clearance, and oil pressure specifications for Leonardo and Scarabeo scooter engines with complete teardown and assembly procedures.

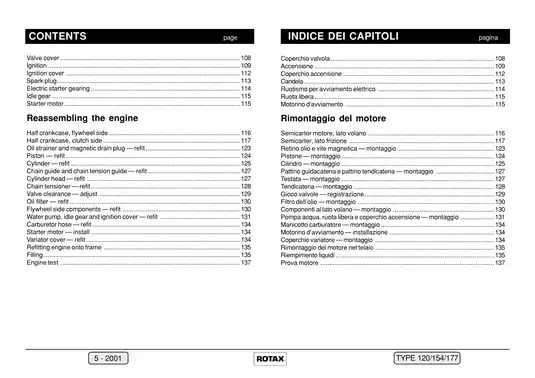

Manual Preview

Sample pages from the 2001 Aprilia Rotax 120/154/177 Workshop Manual (140 P.) manual

Purchase & Download

Models Covered & Key Technical Specifications

Aprilia Leonardo 125 (Type 120), Leonardo 150 (Type 154), Scarabeo 150 (Type 154S), Scarabeo 175/180 (Type 177S) — 2001 Digital Precision Sourcebook | Rotax Engine Record.

- Verified Weight Data: The Leonardo 125 engine is rated at approximately 27 kg dry weight, while Scarabeo models achieve 29 kg dry weight Standards.

- Engineered Net Mass: For optimal performance, the 177S Scarabeo model engine establishes 176.3 cm³ cylinder displacement with 12 kW maximum power output Architecture.

- Prescribed Output Density: The Type 120 achieves 10 kW at 9000 rpm — supports efficient fuel combustion with 124.9 cm³ displacement capacity Margin.

- Nominal Capacity Limits: The transmission requires 95 cm³ (Leonardo) or 110 cm³ (Scarabeo) of HD 75W-90 gearbox oil for proper lubrication Protocol.

- Defined Energy Draw: Maximum spark advance reaches 30° BTDC starting from approximately 4000 rpm, providing 12V 160W direct current generator power Norms.

- General Angular Speed: Engine idle speed governs 1500 rpm minimum rotation, with maximum permissible engine speed achieving 10,000 rpm Guidelines.

Professional Workshop Service Manual & Technical Specifications

Essential Safety Factory Manual: Aprilia Rotax Engine Service Documentation (2001) OEM-Documentation

Asset-ID: Aprilia Leonardo 125 (120), Leonardo 150 (154), Scarabeo 125 (120S), Scarabeo 150 (154S), Scarabeo 175/180 (177S) // Model-Portfolio: Rotax 120/154/177 engine systems and component assemblies // Asset-ID: Complete technical service resource covering displacement 124.9 cm³ to 176.3 cm³, liquid-cooled configuration.

| Integrated-Framework | Rating | Framework |

|---|---|---|

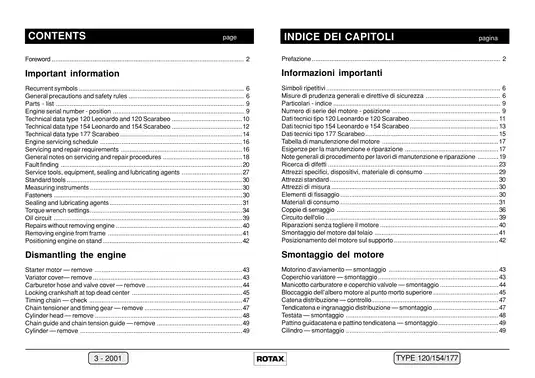

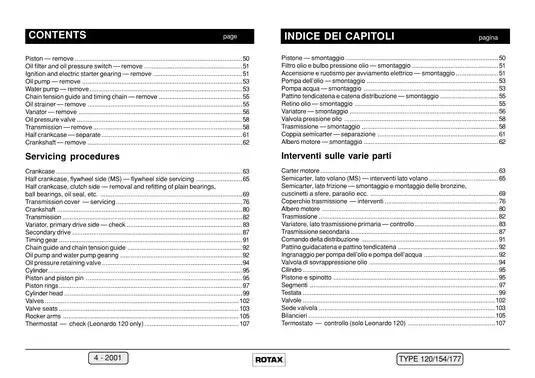

| Engine Dismantling & Component Servicing | Complete | Documentation addresses crankcase separation, timing chain management, cylinder head work, valve servicing, transmission procedures |

| Electrical System & Ignition Architecture | Complete | Battery-powered electronic ignition system with variable spark advance; pick-up sensor data, stator testing, control unit diagnostics |

| Transmission & Drive Systems | Complete | Variator assembly, primary and secondary pulley servicing, centrifugal clutch inspection, belt tension procedures, gearbox oil specifications |

Engineering chapters address the complete engine assembly, beginning with systematic component removal procedures and progressing through detailed servicing instructions for crankcase halves, bearings, and oil seals. The manual documents timing chain inspection methods, chain guide positioning, and tensioner operation to ensure precise valve timing alignment. Cylinder head servicing encompasses valve guide replacement, valve seat re-cutting procedures, spark plug specification data, and valve clearance adjustment sequences at top dead center.

Cooling system maintenance receives dedicated coverage, including water pump inspection, thermostat function verification at approximately 85°C opening temperature, and coolant circuit bleeding procedures. Testing requirements are specified for ignition system components including stator resistance measurement (0.1-1.0Ω for light coils), external pick-up gauge clearance at 11.5±0.1mm, and ignition coil primary winding data. Special procedures are addressed for variator maintenance, distinguishing between type 120/154 greasing protocols and type 177 dry-fitting assembly.

Clearance measurements are addressed for piston-to-cylinder fit (0.04-0.072mm nominal), main bearing journals at three measurement points to determine radial runout (maximum 0.07mm permissible), and crankshaft end float validation (0.2-0.4mm required). The document includes torque specifications for fasteners across all assemblies, with diagrammatic illustrations showing precise wrench sizes and bolt sequences. Reassembly protocols emphasize proper orientation of components such as timing gear prongs into camshaft recesses, thrust washer positioning, and oil seal lip direction toward internal engine chambers.

The manual documents torque specifications for the crankshaft primary drive (60 Nm), transmission cover bolts (11 Nm per standard fastener), cylinder head flange nuts (24 Nm ±1 Nm), and secondary drive assembly (60 Nm) to ensure proper structural assembly and bearing preload. Maintenance intervals are established at 1,000 km, 2,000 km, 6,000 km, and 12,000 km phases, with specifications for engine oil capacity (approximately 1.0 liter), transmission oil quantities (95-110 cm³ depending on model), and coolant mixture ratio (50% antifreeze and 50% water).

FAQ

Customer Reviews

Read what our customers say about this Rotax Engines (Gasoline) manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)