1999 ROTAX Leonardo 120-154 / Scarabeo 120S-154S Engine Workshop Manual

Complete technical reference for Leonardo and Scarabeo gasoline engines. Covers diagnostics, repair procedures, valve clearance adjustment, and transmission service specifications. PN 8140291

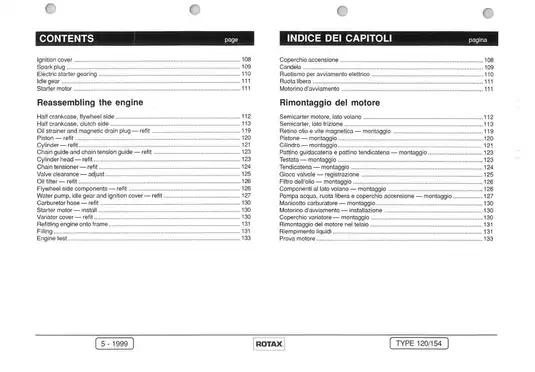

Manual Preview

Sample pages from the 1999 ROTAX Leonardo 120-154 / Scarabeo 120S-154S Engine Workshop Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

ROTAX Leonardo 120–154, Scarabeo 120S–154S — 1999 Structured Engineering Portfolio | Leonardo and Scarabeo Series Repository.

-

Designated Print Rate: Engine displacement is configured at 124.9 cm³ (type 120) and 150.9 cm³ (type 154) representing baseline engine architecture Benchmarks.

-

Verified Dimensional Limits: For maximum performance, bore and stroke limits are set to 56.4 mm / 50 mm (type 120) and 62.0 mm / 50 mm (type 154) establishing precise cylinder geometry Range.

-

Nominal DPI Rating: Compression ratios limits to 12.6 ±0.4:1 (type 120) and 12.35 ±0.4:1 (type 154) producing optimal combustion chamber pressure Sequences.

-

Design Volume Data: Coolant capacity is set to 50% antifreeze and 50% water mixture, regulated at thermostat opening temperature of approximately 75°C (Leonardo 120 only) Baseline.

-

Engineered Running Clearance: Spark plug gap represents 0.7–0.9 mm spacing configured to maintain ignition electrode distance Requirements.

-

Essential RPM Specs: Maximum engine speed is measured at 10,000 rpm representing the governed rotational velocity Threshold.

Professional Workshop Service Manual & Technical Specifications

Consolidated Technical Assembly Manual: Engines (Gasoline) Official Rotax Leonardo 120 - 154, Scarabeo 120S - 154S Engine Manual - Diagnostics & Repair (1999) Documentation-Set

Specification-Class: ROTAX Leonardo 120, Leonardo 154, Scarabeo 120S, Scarabeo 154S (1999) // Engineering-Base: Four-stroke liquid-cooled single-cylinder scooter powerplants with electronic ignition, automatic transmission, and integrated generator systems // Specification-Class: 124.9 cm³ and 150.9 cm³ displacement models producing 10–10.5 kW; multi-language service documentation covering complete maintenance and component replacement protocols.

| Document Overview | Technical Scope | Reference Material Provided |

|---|---|---|

| Service Manual | Engine systems and transmission procedures | Complete specifications documented |

| Bilingual Content | English and Italian technical instructions | Safety protocols and component specifications |

| 136 Pages | Comprehensive workshop resource | Wiring diagrams and technical reference data |

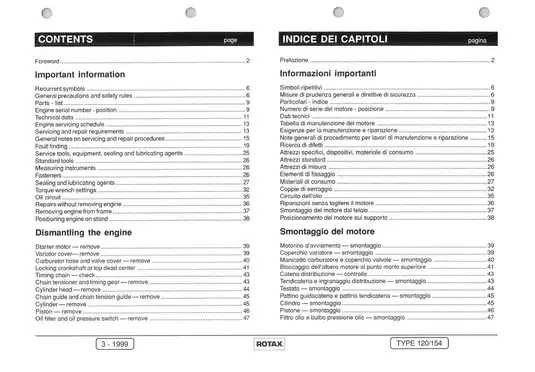

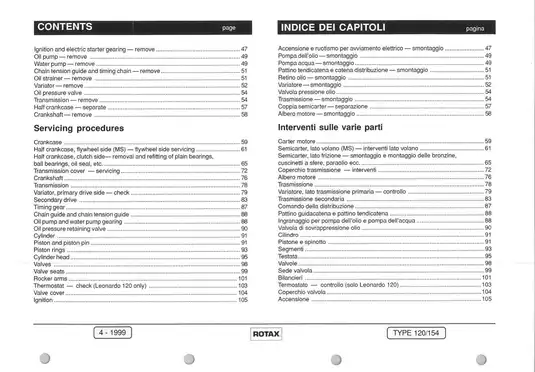

Engineering chapters address crankcase servicing and bearing replacement, followed by transmission component inspection and variator assembly procedures, with chain drive timing system checks, cylinder head valve adjustment documentation, and ignition system electrical troubleshooting guides. The manual encompasses oil circulation pathway analysis, cooling system thermostat function overview, fuel delivery carburetor configuration, and sequential engine reassembly methodology. Systematic coverage presents piston ring clearance measurement protocols, crankshaft end-float calibration processes, oil pump gear examination procedures, and water pump seal replacement operations.

Sequentially requiring technical knowledge and specialized service equipment, this manual provides systematic treatment of engine removal and frame installation, component disassembly methodology, bearing and oil seal replacement techniques, and reassembly sequencing. The document includes torque specifications for fastener installation to ensure proper assembly integrity. Diagnostic procedures are covered for ignition system faults, oil pressure circuit blockages, and thermal regulation anomalies. Wiring diagrams are provided for the 12V battery ignition system, generator output circuits, and electric starter motor control connections. Fuel system procedures are documented for carburetor hose routing, coolant circulation, and oil delivery pathway verification.

This manual documents torque specifications for critical fasteners including crankcase assembly bolts, cylinder head studs, and transmission cover screws to ensure proper assembly integrity. Complete specifications are included for bearing dimensions, oil seal sizing, gasket materials, and piston ring gap measurements. Service tool requirements and lubrication specifications are enumerated throughout, with reference to both synthetic and petroleum-based lubricants suitable for high-temperature engine operation.

FAQ

Customer Reviews

Read what our customers say about this Rotax Engines (Gasoline) manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (5)