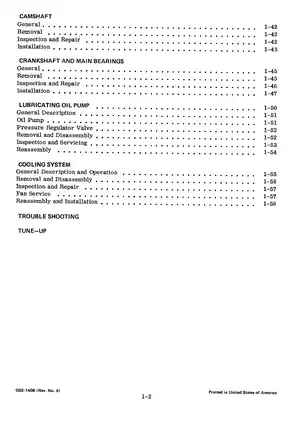

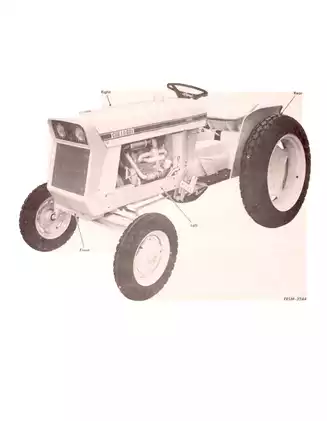

1969-1979 International Cub 154, 184 & 185 Lo-Boy Tractor and Mower Service Manual

Diagnostic procedures and component service for your International Cub Lo-Boy tractor, covering engine removal, installation, and detailed component repair. Ref: GSS-1408

Manual Preview

Sample pages from the 1969-1979 International Cub 154, 184 & 185 Lo-Boy Tractor and Mower Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

1969-1979 International Cub 154, 184 & 185 Lo-Boy Tractor and Mower Service Manual Covers your Lo-Boy tractor with detailed service information for engine, components, and troubleshooting.

- Engine Specifications: 59.5 cubic inches displacement, 7.5:1 compression ratio, 16° BTDC high idle ignition timing.

- Valve Specifications: .015 inch cold valve lash, 45-1/2 degree valve refacing angle.

- Connecting Rod Specifications: 1.625 + .025 inches bearing OD and spread, .002 - .003 inch rod bearing running clearance.

- Piston Specifications: 2.6230 - 2.6234 inches piston diameter, 3 rings per piston.

- Crankshaft Specifications: 1.623 - 1.624 inches main journal diameter, .004 - .008 inch thrust bearing side clearance.

- Timing Gear Specifications: 36 teeth camshaft gear, 90 ft. lbs. idler shaft retainer bolt tension.

Professional Workshop Service Manual & Technical Specifications

Commercial Calibration Training Manual: Tractor Service Manual for International Cub 154, 184 and 185 Lo-Boy Tractors and Mowers 1969-1979 Overhaul-Reference

Product-Line: Tractor // Repair-Classification: Engine & Drivetrain Logic // Operational-Scope: Service Procedures. The documentation provides guidance on:

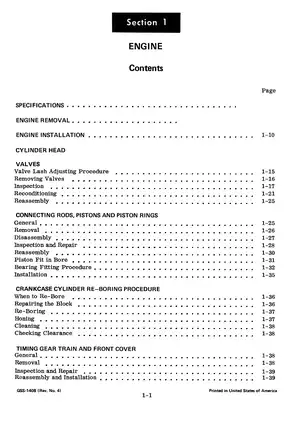

Engine

Specifications Engine Removal Engine Installation

Cylinder Head

Valves Connecting Rods, Pistons and Piston Rings Crankcase Cylinder Re-Boring Procedure Timing Gear Train and Front Cover

Camshaft

Crankshaft and Main Bearings Lubricating Oil Pump Cooling System Trouble Shooting Tune-Up

Carburetor

Specifications General Description Carburetor Operation Liquid Level Check (Carburetor on Engine) Removal and Installation of Carburetor Inspection and Repair Diagnosing Engine Troubles Fuel System Conditions Affecting Power Loss Fuel System Conditions Affecting Fuel Economy Principles of Operation Governor Removal, Inspection and Repair Adjustments

Main Clutch Shaft and Engine Clutch

154 & 185 Tractors (Below Serial No. U018709) 154 & 185 Tractors (Above Serial No. U018709) 184 Tractor Adjustments

Transmission and Differential

Specifications Transmission Countershaft spacer lengths Differential General

Creeper Drive (154 & 185 Tractors)

Removal Disassembly Inspection and Repair Reassembly

Creeper Drive (184 Tractor)

Removal Installation

Final Drive and Brakes

Specifications Final Drive Rear Axles Differential Shafts Brakes Brake Adjustment - Single Pedal Brakes Brake Adjustment - Two Pedal Brakes

Independent Power Take-Off and Mower

154 & 185 Tractors Checks Before Removal Removal Disassembly Inspection and Repair Reassembly and Installation IPTO Adjustments 184 Tractor Electric IPTO Clutch and Drive Shaft Assembly Drive Belt Replacement MOWER Mower Spindle Assembly Drive Belt Tension Blade Care

Hydraulic Lift and Three-Point Hitch

CONTENTS Specifications Hydraulic Lift Checking the Hydraulic System Hydraulic Pump Control Valve Circuit Relief Valve Hydraulic Cylinder (Cessna) Hydraulic Cylinder (IH) Three-Point Hitch Removal Adjustments Lift Links and Leveling Screws Hitch Upper Link

Electrical

CONTENTS SPECIFICATIONS 154 & 185 TRACTORS Motor Generator Voltage Regulator Distributor Electric PTO Clutch WIRING DIAGRAM 154 & 185 TRACTORS SAFETY STARTING CIRCUIT SPECIFICATIONS 184 TRACTOR WIRING DIAGRAM SAFETY STARTING CIRCUIT RESISTOR UNIT This manual details procedures for the disassembly, inspection, repair, and reassembly of various tractor components. Structured guidance covers engine systems, fuel delivery, lubrication, cooling, ignition, and more. It documents torque specifications for cylinder head installation to ensure proper seal compression uniformity.

FAQ

Customer Reviews

Read what our customers say about this International Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (4)