1967-1969 Cub Cadet Tractor 72/104/105/124/125 Service Manual

Troubleshooting, parts diagrams, and service data for Kohler K-161S, K-241AS, and K-301AS engines. Complete transmission, differential, clutch, and hydrostatic drive procedures. PN GSS-1398

Manual Preview

Sample pages from the 1967-1969 Cub Cadet Tractor 72/104/105/124/125 Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

International Cub Cadet Models 72, 104, 105, 124, and 125 (GSS-1398) — 1967–1969 Precision Engineering Vault | Cub Cadet Series Repository.

- Engineered Operational Speed: The governed engine speed is established at 3600 rpm minimum idle without load and rises to 3800 rpm maximum full load operation Mapping.

- Design Unit Dimensions: For the Model 72 variant, 2-7/8 inches represents the cylinder bore measurement Configuration.

- Documented Print Quality: Cylinder block specifications are standardized to achieve 16.23 cu. inches for Model 72 displacement Benchmarks.

- Principal Tank Capacity: The fuel system reaches 3.5 gallons tank volume for standard operation Range.

- Advanced Dimensional Tolerance: Crankpin diameter is established at 1.1855 to 1.1860 inches new specification for Model 72 Baseline.

- Primary Production Rate: Rated horsepower yields 7.0 hp at 3600 rpm for the Kohler K-161S engine assembly Sequences.

Professional Workshop Service Manual & Technical Specifications

Detailed Workshop Workshop Manual: Tractor Official Cub Cadet Tractor 72, 104, 105, 124, 125 - Comprehensive Service & Repair Manual Procedure-Library

Validation-Data: Models 72, 104, 105, 124, 125 (1967-1969) // System-Coverage: Multi-system engine and transmission framework / Hydraulic and mechanical components // Application-Range: International Cub Cadet tractor service documentation for comprehensive workshop reference.

| Assessment-Parameter | Rating | Calibration-Data |

|---|---|---|

| Engine Systems Documentation | Complete | Includes specifications for K-161, K-241, K-301 engines across models |

| Transmission Coverage | Comprehensive | Gear-drive and hydrostatic transmission procedures documented |

| Electrical System Reference | Full Coverage | Magneto and battery ignition circuits with wiring diagrams included |

| Hydraulic Systems | Documented | Models 105 and 125 hydrostatic transmission principles and service procedures |

| Chassis Components | Complete | Steering, brakes, clutch, and final drive assemblies covered |

Table of Contents Summary: The documentation is partitioned into detailed engine specifications covering cylinder bore, stroke, and displacement parameters alongside general information sections, continues with fuel system and carburetor adjustment references, incorporates electrical system diagrams for magneto and battery configurations, addresses transmission and differential assembly procedures, details hydrostatic transmission operation for applicable models, and concludes with chassis adjustments and equipment service information for mowers and tillers.

Core Nexus

The manual provides comprehensive technical data across five tractor models spanning multiple engine variants. Specifications for valve clearances, bearing tolerances, and piston-to-cylinder clearances are documented throughout the engine section. The fuel system chapter covers carburetor component identification and assembly sequences. Electrical system documentation includes wiring diagrams for both magneto and battery ignition systems with regulator adjustment references included in the manual.

Systematic Protocol

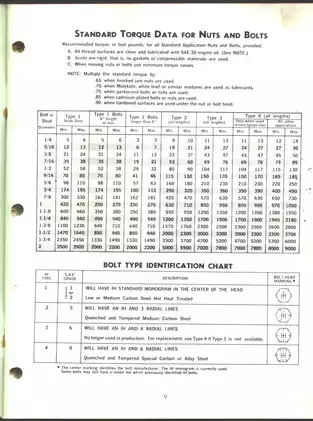

Alignment specifications are included for front axle steering geometry with toe-in and caster angle reference data documented. The transmission section contains detailed specifications for gear spacing, bearing preload limits, and differential backlash measurements. The manual documents torque specifications for critical fasteners including engine head bolts, connecting rod fasteners, and transmission assembly bolts to ensure proper component retention. Service bulletins and special tools required are listed at the manual's beginning for technician reference.

Advanced Framework

Reference data is included for hydrostatic transmission principles explaining fluid pressure, flow direction, and pump displacement control across models 105 and 125. The document covers charge pump service procedures, relief valve adjustment, and check valve maintenance with component identification provided. Troubleshooting sections address erratic speed operation and movement issues with diagnostic steps outlined for verification of charge pump and valve function. Wiring diagrams are provided for tractor electrical systems showing battery, generator, and ignition circuit connections with terminal identification marked.

Systematic Architecture

This manual covers clutch assembly service including removal, disassembly, and reassembly procedures with spring tension specifications documented. Brake adjustment reference data is included with brake engagement zone definitions and clearance measurements specified. Reduction drive and creeper attachment sections contain bearing arrangement details and gear ratio information. The rear axle section documents bushing and bearing service for differential-driven shafts with snap ring retention procedures referenced.

Comprehensive Protocol

Diagnostic procedures are covered for recoil starter inspection and reassembly with spring preload specifications included. The front PTO clutch section contains pressure spring adjustment procedures and bearing snap ring positioning details. Mower spindle assembly documentation includes bearing cone replacement sequences and blade nut torque specifications. The rotary tiller section addresses tine positioning requirements for proper knife-edge alignment with gear box service procedures documented for backlash verification and bearing inspection protocols.

The manual documents torque specifications for the connecting rod assemblies to ensure proper fastener retention and prevent mechanical failure.

Sources: International Harvester Company (1969). International Cub Cadet Tractor Service Manual (Models 72, 104, 105, 124, 125). GSS-1398.

FAQ

Customer Reviews

Read what our customers say about this Cub Cadet Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (2)