1967-1969 International Cub Cadet 72/104/105/124/125 Operator's Manual

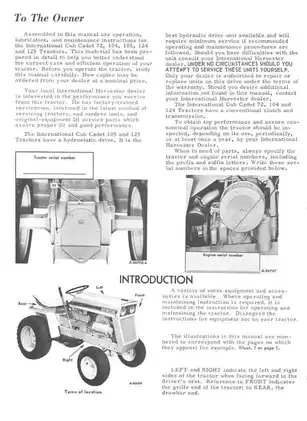

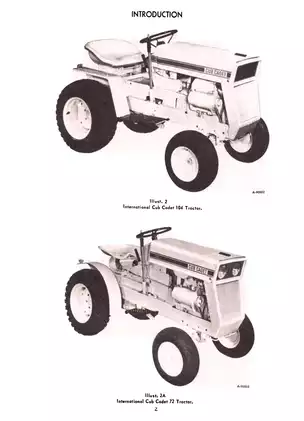

Complete operating instructions for International Cub Cadet small tractors — starting, fuel system, electrical, clutch/brake, hydraulics, and routine maintenance procedures with adjustment specifications.

Manual Preview

Sample pages from the 1967-1969 International Cub Cadet 72/104/105/124/125 Operator's Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

International Cub Cadet 72, 104, 105, 124, 125 — 1967–1969 Functional Primer Vault | Cub Cadet Series Kit.

- Prescribed Load Capacity: The hydraulic pump is rated at 2.5 gallons per minute at pressures up to 400 PSI Bounds.

- Standard Environmental Range: For optimal operation, engine oil change is specified as every 30 hours of operation Matrix.

- Core RPM Specs: Spark plug gap is set at 0.025-inch (0.635 mm) to establish proper ignition spacing Standards.

- Rated Installation Footprint: The motor-generator belt is designed for 1/4-inch maximum deflection with ten pound force applied midway Topology.

- Technical Threaded Fastener Data: Breaker points gap governs 0.020-inch (0.508 mm) spacing for accurate timing Protocol.

- Advanced Voltage Specs: The clutch release clearance is set to 0.050-inch (1.27 mm) to maintain proper brake engagement Margin.

Professional Workshop Service Manual & Technical Specifications

Definitive Quality Manual: International Cub Cadet 72, 104, 105, 124, and 125 Tractors Specification-Guide

Procedure-Type: International Cub Cadet 72, 104, 105, 124, 125 (1967-1969) // Component-Focus: Operator and maintenance systems / Transmission logic // Subsystem-Focus: Engine, electrical, hydraulic, and drivetrain documentation.

| Service-Nexus | Diagnostic-Logic | Framework |

|---|---|---|

| Engine Systems | Fuel and ignition circuit operation | Carburetor and spark plug specifications documented |

| Electrical Architecture | Starting and charging function | Motor-generator belt and regulator reference data |

| Transmission Operations | Gear selection and creeper drive | Speed table and clutch clearance parameters |

| Hydraulic Power Unit | Equipment control and lift function | Fluid capacity and pressure safety valve documented |

| Tire and Chassis | Front wheel geometry and inflation | Terra-Tire inflation and toe-in reference data |

Technical chapters are organized around engine startup procedures, fuel system maintenance, electrical component identification, and transmission operation across creeper and direct drive modes. The documentation addresses clutch and brake adjustment protocols, covers engine cooling requirements and air cleaner maintenance, and provides detailed lubrication schedules for steering components and transmission housings. System operation descriptions incorporate hydraulic cylinder control, front wheel toe-in specification, and tire care guidance for both standard and Terra-Tire equipment.

Advanced Benchmarks

Properly requiring operator familiarity with engine ignition timing, the manual documents reference points for breaker point gap adjustment and spark plug inspection intervals. The electrical circuit includes components such as the twelve-volt motor-generator, voltage regulator, safety starting switch, and storage battery management protocols. Wiring diagrams present cable routing for the charge indicator, ignition system, and lighting switches to facilitate troubleshooting of electrical connections.

Comprehensive Protocol

Wear limits are specified for multiple drivetrain components, including clutch pedal free movement, brake engagement distance, and creeper drive adjustment parameters. The documentation addresses engine oil viscosity selection based on operating temperature ranges, with distinct lubrication tables for Models 72, 104, and 124 tractors compared to Models 105 and 125 tractors. Transmission and creeper drive housing oil change intervals are documented, along with greasing schedules for front axle pivot pins, steering knuckles, and steering gear housing assemblies.

Technical Threshold

System operation descriptions cover carburetor high-speed and idle adjustment techniques, including fuel mixture lean-out procedures and throttle stop positioning. The documentation includes hydraulic system fill procedures using IH Hy-Tranle or equivalent SAE 10W engine oil, with fluid capacity reference of approximately 3 pints for the self-contained gear pump assembly. Assembly instructions are detailed for motor-generator belt installation, including tension adjustment methods using deflection measurement between pulleys.

Operational Framework

Hydraulic schematics are included for the directional control valve, companion cylinder, and safety relief valve that protects against system overload. The manual provides troubleshooting guidance for engine overheating, lack of power conditions, and creeping behavior in neutral position on hydrostatic drive models. Reference data documents torque specifications for bolt fastening to ensure proper joint separation prevention during assembly and maintenance operations.

Engineered Framework

The document includes specifications for sealed-beam headlights, fuse capacity ratings, and taillight lamp wattage requirements across all model variants. Front wheel turning radius adjustments using drag link ball joint manipulation are documented, along with tie rod modification techniques for toe-in correction. Spark plug gap settings, breaker point spacing measurements, and ignition timing sight hole locations are referenced for each model generation.

FAQ

Customer Reviews

Read what our customers say about this Cub Cadet Tractor manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (1)