1998 Jeep Cherokee XJ Service Manual

Complete 1998 Jeep Cherokee XJ service and repair manual for 2.5L and 4.0L engines. Includes diagnostics, maintenance schedules, and component procedures. Part number: FSM2.

Manual Preview

Sample pages from the 1998 Jeep Cherokee XJ Service Manual manual

Purchase & Download

Models Covered & Key Technical Specifications

1998 Jeep Cherokee XJ Factory Service Manual This comprehensive factory service manual covers the 1998 Jeep Cherokee XJ 4x4 and 4x2 models with 2.5L and 4.0L engines. It provides detailed procedures, diagrams, and specifications for all major systems.

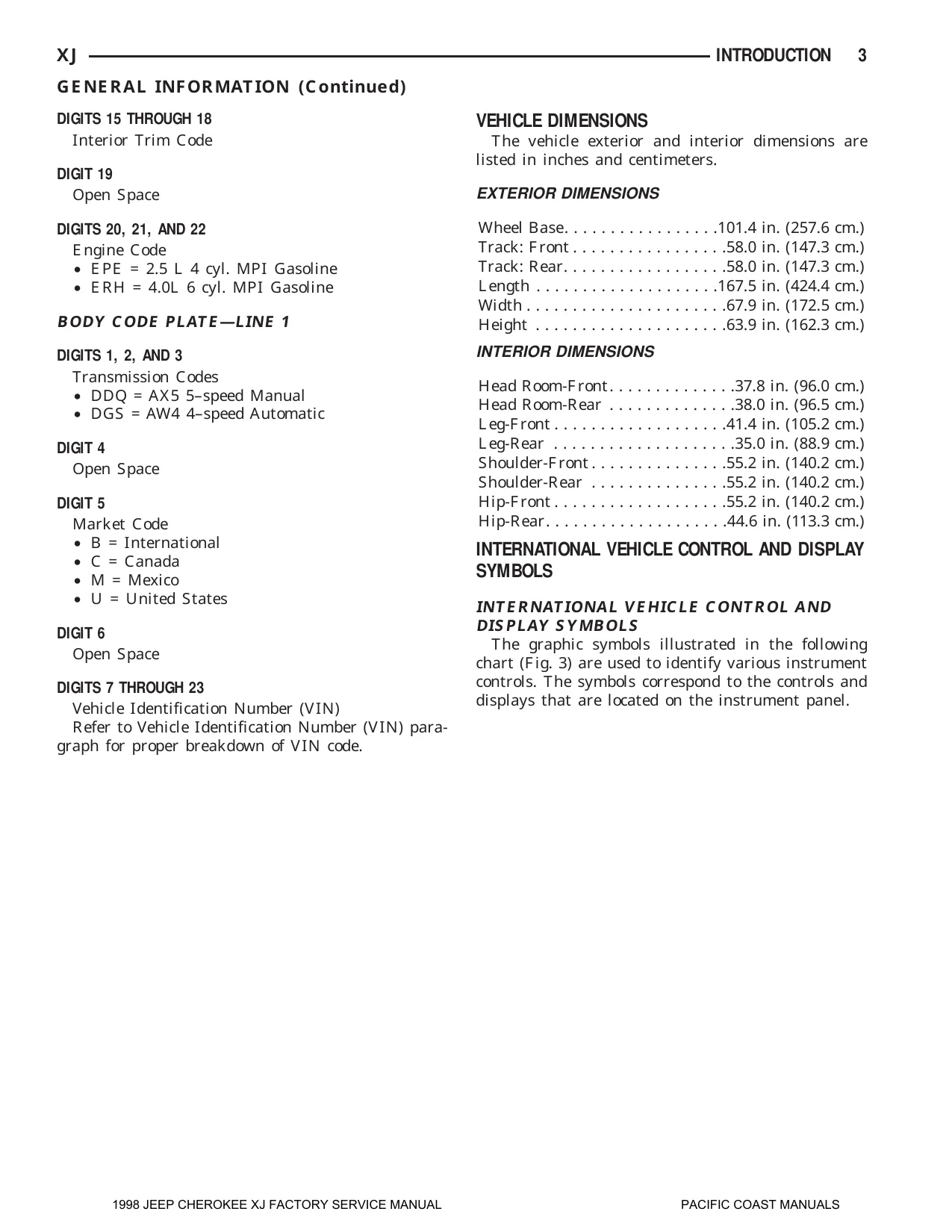

Engine Identification & Configuration:

- Jeep Cherokee XJ (1998) | Variant: 2.5L Gasoline (MPI) | Code: EPE | VIN Digit 8: P

- Jeep Cherokee XJ (1998) | Variant: 4.0L Gasoline (MPI) | Code: ERH | VIN Digit 8: S

- Jeep Cherokee XJ (1998) | Firing Order: 1-3-4-2 (2.5L) | 1-5-3-6-2-4 (4.0L)

Powertrain & Transmission Systems:

- Jeep XJ 5-Speed Manual (HD) | Model: AX15 | Fluid: 3.1L - 3.15L | Code: DDQ

- Jeep XJ 4-Speed Automatic | Model: AW4 | Fluid: 8.0L (Dry Fill) | Code: DGS

Driveline & Chassis Architecture:

- Jeep XJ Front Axle | Model 181-FBI (Dana 30) | Fluid: 1.48L | Nut Torque: 237 N·m

- Jeep XJ Rear Axle | Model 194-RBI (Dana 35) | Fluid: 1.66L | Trac-Lok Additive: 3.5-4.0 oz

Technical Fastener & Torque Matrix:

- Engine Component | Cyl. Head (4.0L): 149 N·m (Max) | Spark Plugs: 35-41 N·m

- Suspension | Lower Arm: 115 N·m | Track Bar: 100 N·m

Fluid & Capacity Specifications:

- Lubrication | 2.5L Engine: 3.8L | 4.0L Engine: 5.7L

- Thermal Management | Cooling System (4.0L): 11.4L

Professional Workshop Service Manual & Technical Specifications

1998 Jeep Cherokee XJ SUV Comprehensive Factory Service Manual

Subsystem-Focus: Powertrain and Driveline Logic // Conceptual-Layout: Complete Vehicle Schematics / Component Overviews // Maintenance-Category: Scheduled Service and Repair Procedures

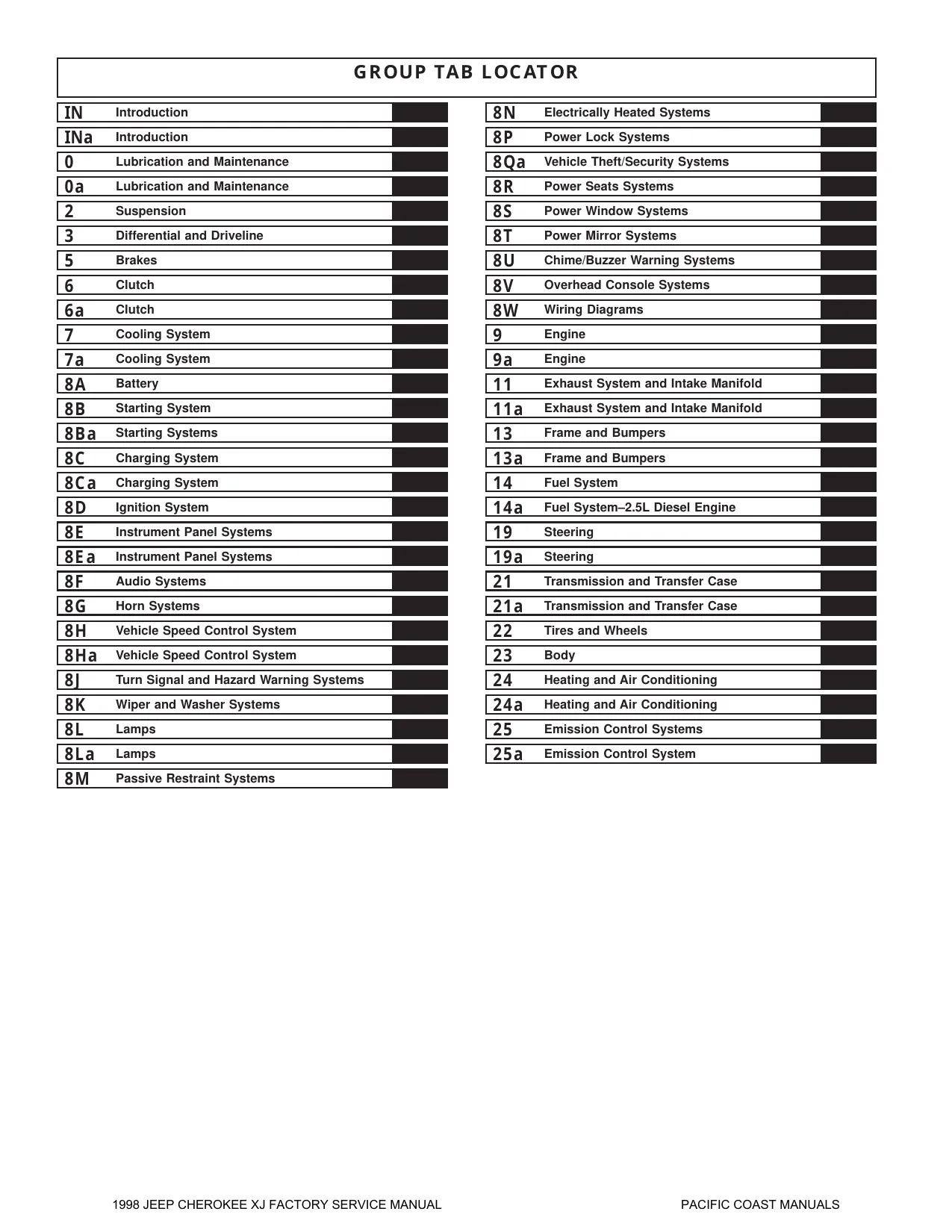

This extensive service manual details the inner workings of the 1998 Jeep Cherokee XJ SUV, covering everything from basic maintenance to complex component overhauls. It provides a thorough understanding of the vehicle's systems.

Service sections detail the function and repair of critical vehicle systems, including the engine, transmission, driveline, suspension, and braking systems. Wiring diagrams and diagnostic procedures are also included to aid in troubleshooting and repair.

The manual includes detailed instructions for the removal and installation of major components such as the engine, transmission, axles, and suspension parts. Rigorous procedures ensure that repairs are performed correctly and safely.

A comprehensive overview of the vehicle's electrical system is provided, covering the starter, charging systems, ignition, and lighting. Diagnostic charts are included to help identify and resolve electrical issues.

Torque specifications for critical components are documented to ensure proper assembly and clamp load consistency.

FAQ

Customer Reviews

Read what our customers say about this Jeep SUV manual and share your own experience.

Add a Review

This policy contains information about your privacy. By posting, you are declaring that you understand this policy:

- Your name, rating, website address, town, country, state and comment will be publicly displayed if entered.

- Aside from the data entered into these form fields, other stored data about your comment will include:

- Your IP address (not displayed)

- The time/date of your submission (displayed)

- Your email address will not be shared. It is collected for only two reasons:

- Administrative purposes, should a need to contact you arise.

- To inform you of new comments, should you subscribe to receive notifications.

- A cookie may be set on your computer. This is used to remember your inputs. It will expire by itself.

This policy is subject to change at any time and without notice.

These terms and conditions contain rules about posting comments. By submitting a comment, you are declaring that you agree with these rules:

- Although the administrator will attempt to moderate comments, it is impossible for every comment to have been moderated at any given time.

- You acknowledge that all comments express the views and opinions of the original author and not those of the administrator.

- You agree not to post any material which is knowingly false, obscene, hateful, threatening, harassing or invasive of a person's privacy.

- The administrator has the right to edit, move or remove any comment for any reason and without notice.

Failure to comply with these rules may result in being banned from submitting further comments.

These terms and conditions are subject to change at any time and without notice.

Reviews (3)